Loading...

Loading...

Do you have a question about the Canon imagePRESS C7000VP Series and is the answer not in the manual?

Error code E000-0102 indicates the fixing belt did not separate from the fixing roller.

Error E007-0001 caused by improper position of tracking detection arm adjustment plate.

Error E012-0180 caused by omission of primary transfer roller pressurization.

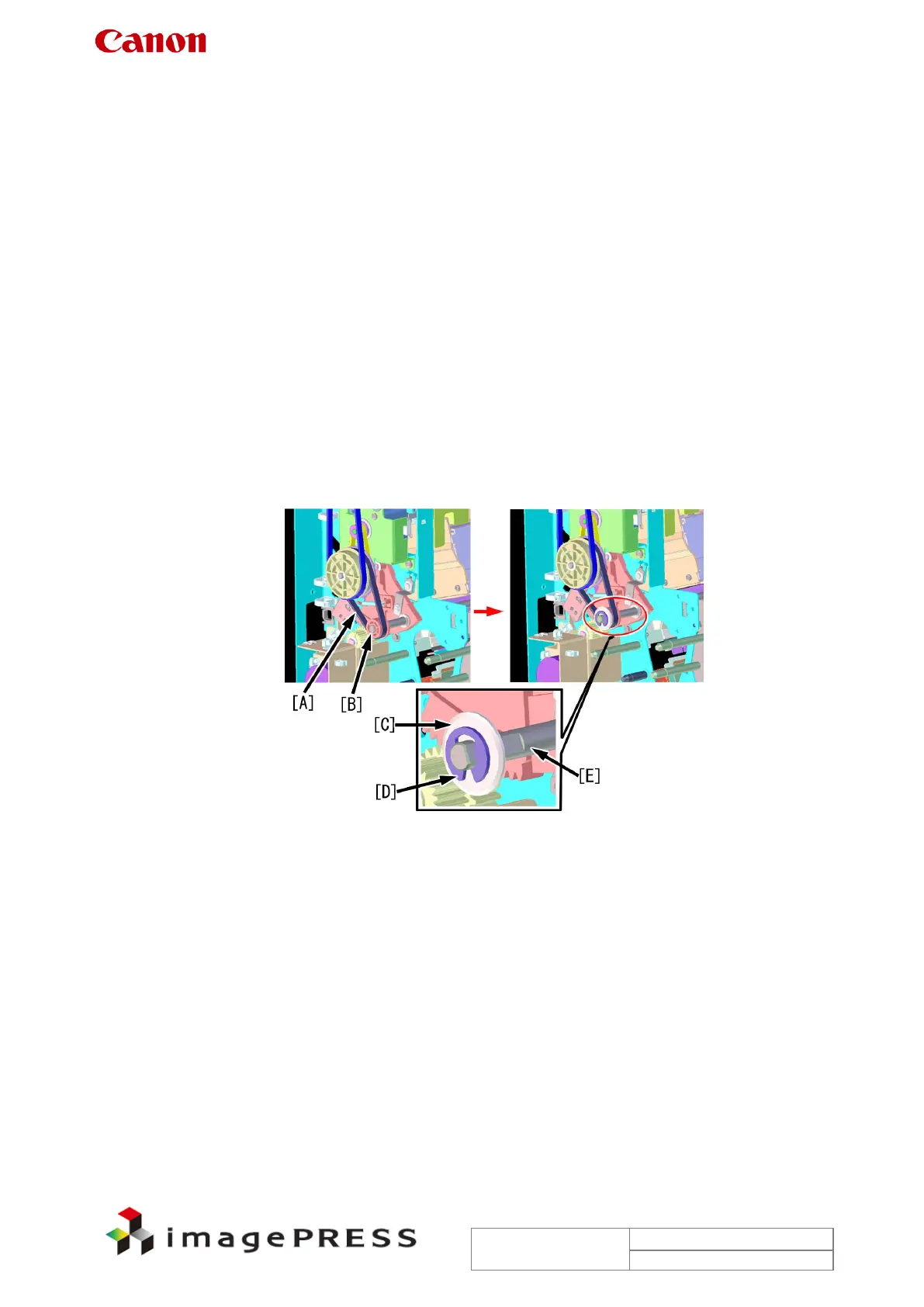

Error E014-0100 caused by chipped transmission shaft in fixing assembly.

Error E016-0x00 caused by feed screw of photosensitive drum cleaner locking.

Errors E018-0x11, E018-0x13, E018-0102 related to drum patch shutter or sensor issues.

Error E061-0181 is a low laser power error due to deformed H.V. cable spring terminal.

Error E062-0300 caused by insecurely fitted connector of Process Unit Driver PCB.

Error E065-0201 due to primary corona high voltage leakage at drum end of life.

Error E077-0001 when secondary transfer external roller engagement fails within 5 sec.

Error E078-0001 when ITB cleaner motor does not rotate.

Error E202-0001 caused by pinched cooling fan harness on Interface PCB.

Errors E260/E227 series due to insecurely fitted connectors in 24V power supply 2.

Error E260-2004 caused by tie-wrap on harness between DC-CON and ITB driver PCB.

Error E512-8011 when stack tray overruns lower limit position.

Error E514-8001 observed due to slight weight difference in rail assembly.

Error E578 due to stapling more than the specified number of sheets.

Error E590-8003 occurs when dipswitch setting does not match punch unit.

Error E747-051B when S-B PCB was faulty.

Error E750-0002 due to mistaken connector connection after relocation.

Error E750-2012 when fixing intermediate assembly connectors are not reattached.

Error E804-0001 detected when a power supply fan error occurs.

Error E805-0404 after replacement of fixing/feeder driver assembly.

Error E805-0701 indicated due to wire pinching of cooling fan 1.

Error E822-0903 due to poor contact of fixing duplexing drawer.

Errors E020-0x81 to E020-0xB1 related to drum base and toner density sensor.

E194 and Color Registration Failure due to factor analysis and workflow.

Error E842-0211 when ball bearing in pressure roller drive assembly breaks.