7B -- 30 MANUAL CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM

DAEWOO M-150 BL2

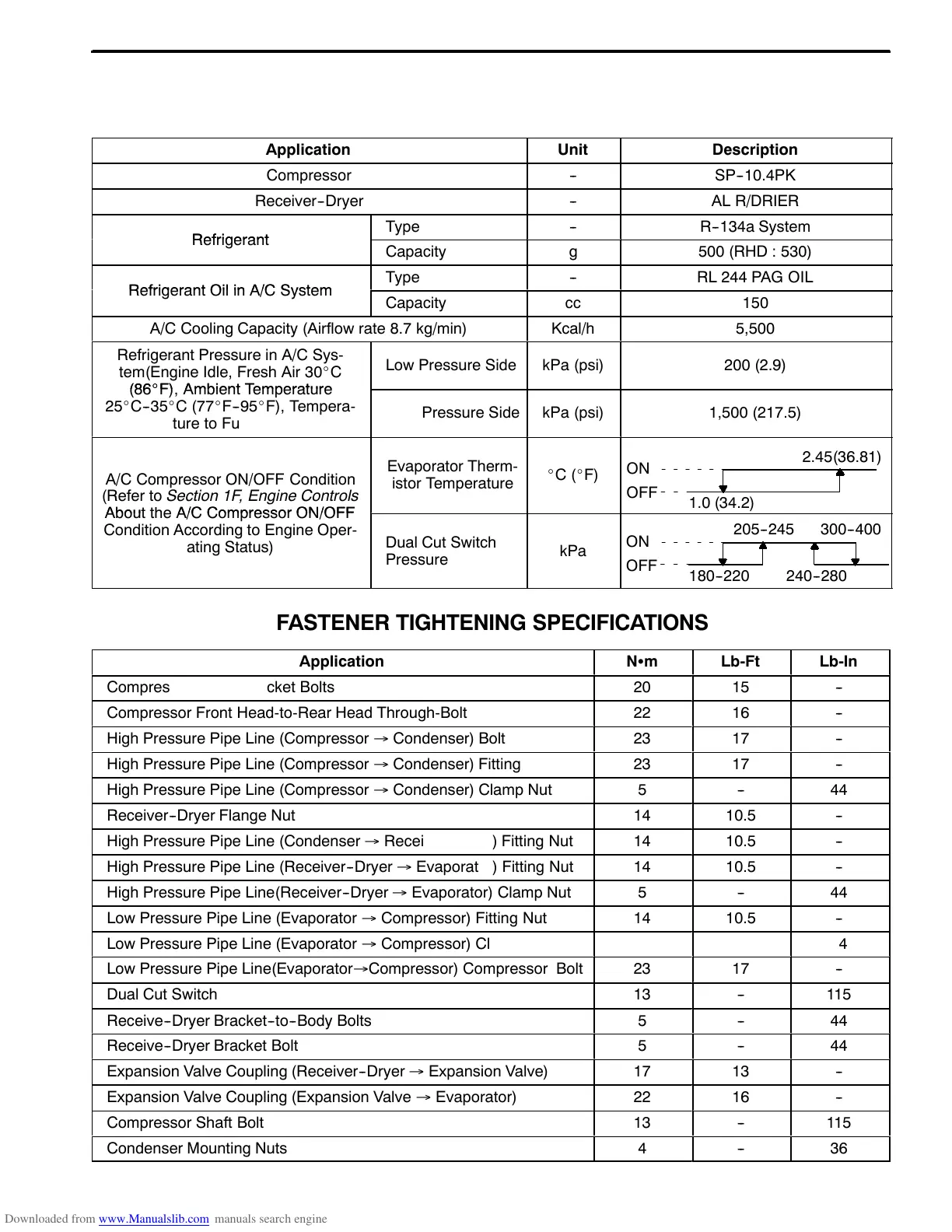

SPECIFICATIONS

GENERAL SPECIFICATIONS

Application

Unit

Description

Compressor

--

SP--10.4PK

Receiver--Dryer

--

AL R/DRIER

Type

--

R--134a System

e

r

gerant

Capacity

g

500 (RHD : 530)

Type

--

RL 244 PAG OIL

e

r

gerant

n

ystem

Capacity

cc

150

A/C Cooling Capacity (Airflow rate 8.7 kg/min)

Kcal/h

5,500

Refrigerant Pressure in A/C Sys-

tem(Engine Idle, Fresh Air 30_C

_

Low Pressure Side

kPa (psi)

200 (2.9)

_

,

m

ent

emperature

25_C--35_C(77_F--95_F), Tempera-

ture to Full Cold)

High Pressure Side

kPa (psi)

1,500 (217.5)

A/C Compressor ON/OFF Condition

(Refer to Section 1F, Engine Controls

Evaporator Therm-

istor Temperature

_C(_F)

2.45(36.81)

1.0 (34.2)

ON

OFF

out t

e

ompressor

Condition According to Engine Oper-

ating Status)

Dual Cut Switch

Pressure

kPa

205-- 245

180-- 220

ON

OFF

300-- 400

240-- 280

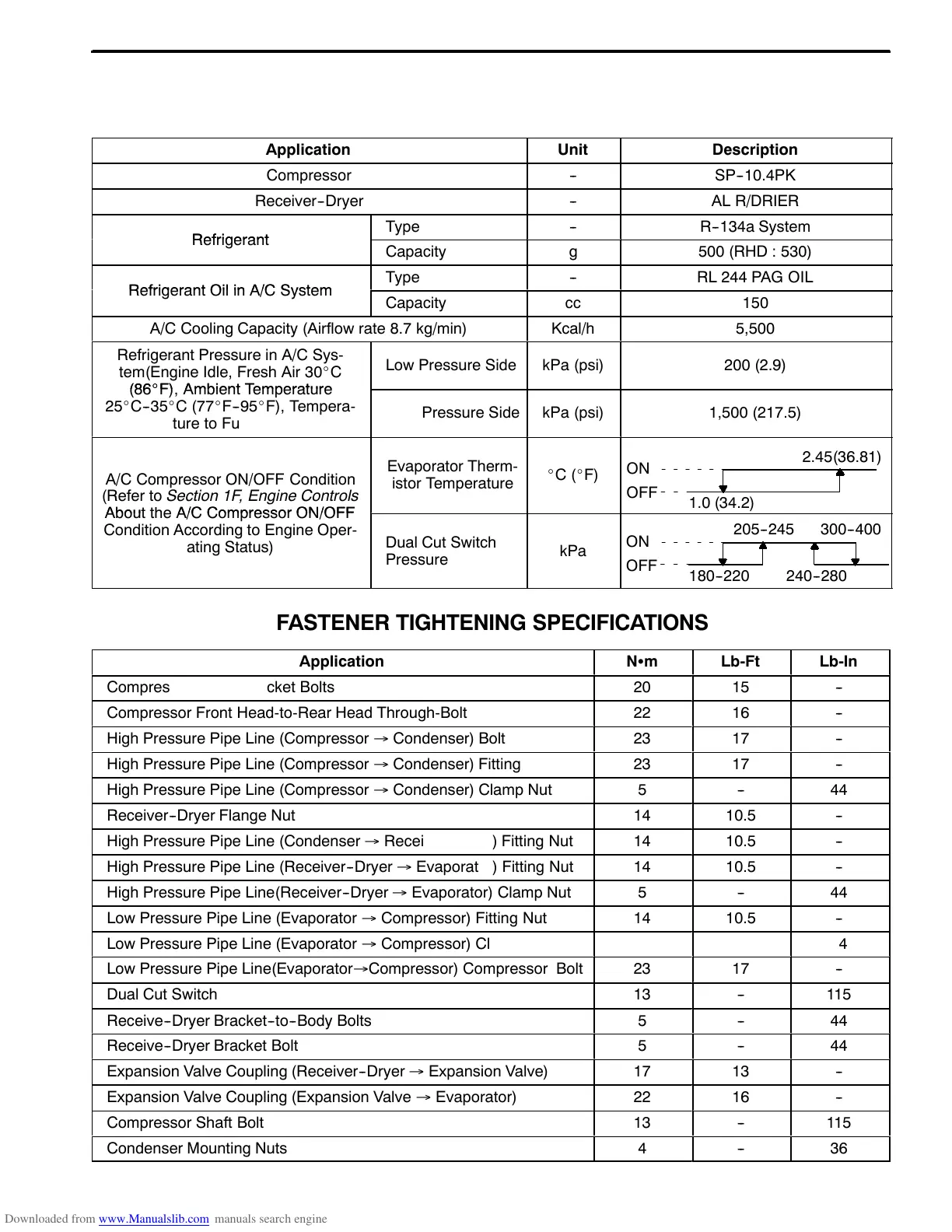

FASTENER TIGHTENING SPECIFICATIONS

Application

NSm

Lb-Ft

Lb-In

Compressor Upper Bracket Bolts

20

15

--

Compressor Front Head-to-Rear Head Through-Bolt

22

16

--

High Pressure Pipe Line (Compressor → Condenser) Bolt

23

17

--

High Pressure Pipe Line (Compressor → Condenser) Fitting

23

17

--

High Pressure Pipe Line (Compressor → Condenser) Clamp Nut

5

--

44

Receiver--Dryer Flange Nut

14

10.5

--

High Pressure Pipe Line (Condenser → Receiver--Dryer) Fitting Nut

14

10.5

--

High Pressure Pipe Line (Receiver--Dryer → Evaporator) Fitting Nut

14

10.5

--

High Pressure Pipe Line(Receiver--Dryer → Evaporator) Clamp Nut

5

--

44

Low Pressure Pipe Line (Evaporator → Compressor) Fitting Nut

14

10.5

--

Low Pressure Pipe Line (Evaporator → Compressor) Clamp Nut

5

--

44

Low Pressure Pipe Line(Evaporator→Compressor) Compressor Bolt

23

17

--

Dual Cut Switch

13

--

115

Receive--Dryer Bracket--to--Body Bolts

5

--

44

Receive--Dryer Bracket Bolt

5

--

44

Expansion Valve Coupling (Receiver--Dryer → Expansion Valve)

17

13

--

Expansion Valve Coupling (Expansion Valve → Evaporator)

22

16

--

Compressor Shaft Bolt

13

--

115

Condenser Mounting Nuts

4

--

36

Loading...

Loading...