Maintenance 8. Arm #4

136 G3 Rev.14

8.2 Replacing the Timing Belt

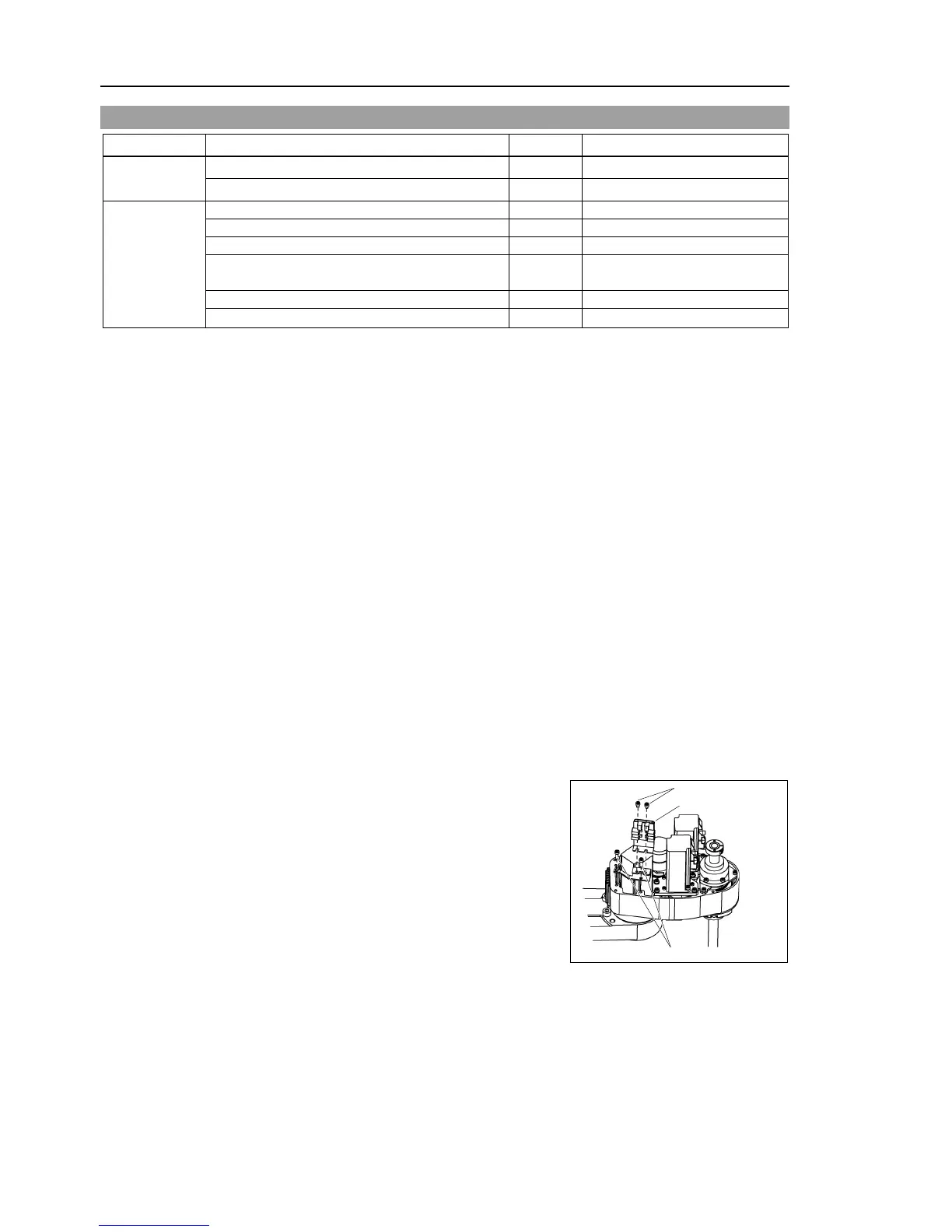

Name Quantity Note

Maintenance

parts

Hexagonal wrench (width across flats: 3 mm)

Spanner (width across flats: 7 mm)

Belt tension

98N (10 kgf) / 74N (7.5kgf)

Suitable cord (Length about 800 mm)

A brake is mounted on the motor of Joint #3 to prevent the shaft from lowering due to the

weight of the end effector while the power to the Controller is OFF or while the motor is

in OFF status (MOTOR OFF).

Note that the brake will not work during the replacement procedure.

Move the shaft down to its lower limit before the replacement procedure following the

removal steps from (1) to (3).

Push down the shaft to its lower limit while pressing the brake release switch. Be

sure to keep enough space and prevent the

hitting any peripheral

equipment.

The brake release switch affects only Joint #3. When the brake release switch is

pressed, the brake for Joint #3 is released simultaneously.

shaft while the brake release switch is being pressed because

the

shaft may be lowered by the weight of an end effector

top cover and the arm bottom cover.

For details, refer to Maintenance: 3. Covers.

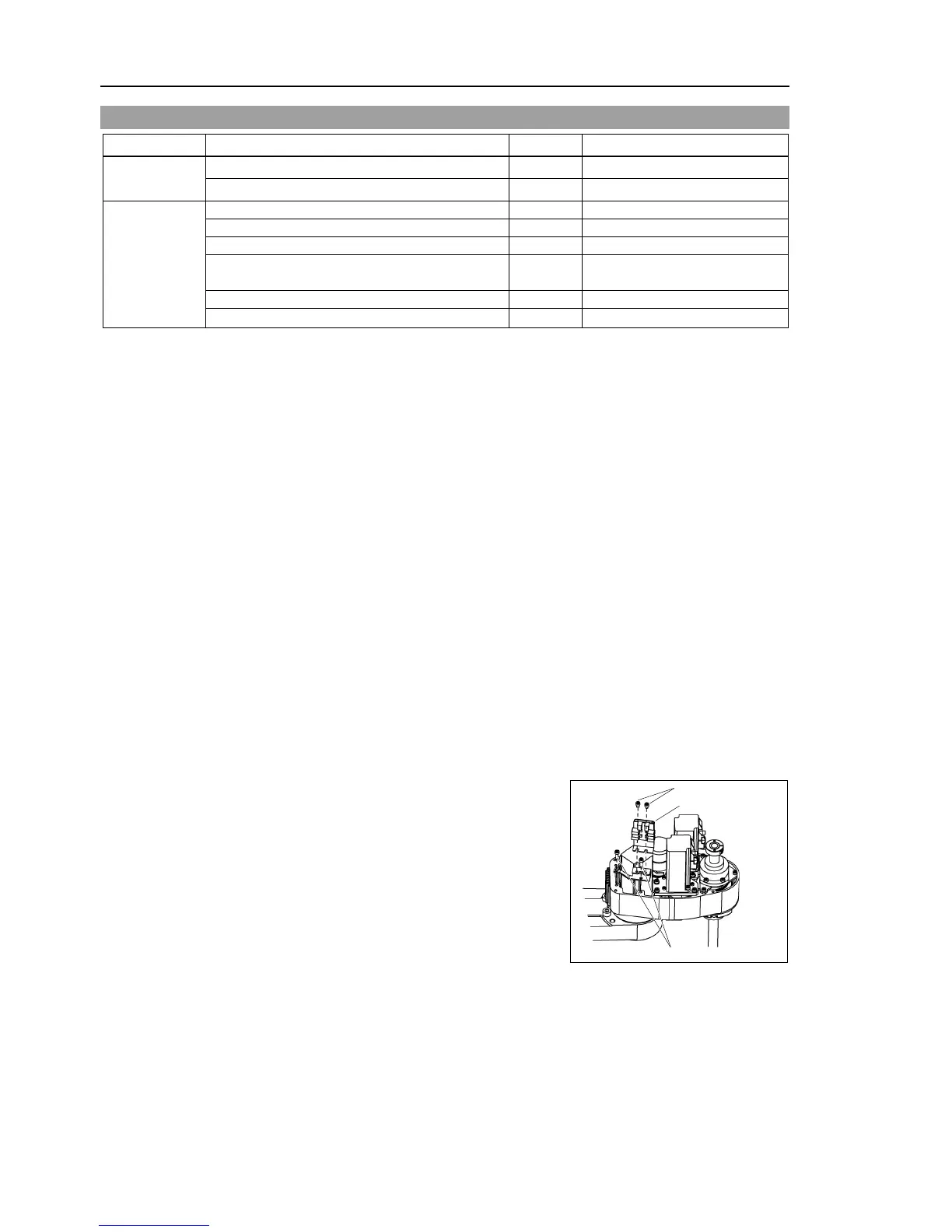

the battery board and mounting metal

Remove the user plate and ground wire

Cut off a wire tie bundling the motor cables and

signal cables.

Disconnect the following connectors.

Connectors X231, X241, X31, X32, X41 (Hold the claw to remove.)

Connector X63, X64 (for backup cable connector of Joint #3 and 4)

Loading...

Loading...