4

3

2

1

4

3

2

1

4. Testing and calibrating the edger

If you notice deviations in the job, or encounter difficulties while using the touch screen,

You can:

an inspection of the calibration of the position of the feeler in the trough, (p.128)

calibrate the touch screen (p.129).

If the edger detects a variation, an adjustment is carried out during the cycle.

a. Control the calibration of the monofeeler

If the beveling or chamfering are misaligned, the edger may need to be recalibrated.

You can perform a calibration inspection of the position of the monofeeler in the trough.

At the time of the cycle of calibration of the feeler, the edger takes into account the wear of the feelers since the last

calibration and adjusts it to mitigate any possible variation.

Have the plastic calibration gauge to hand.

Press on > > > to reach the menu of calibration.

The following screen is displayed:

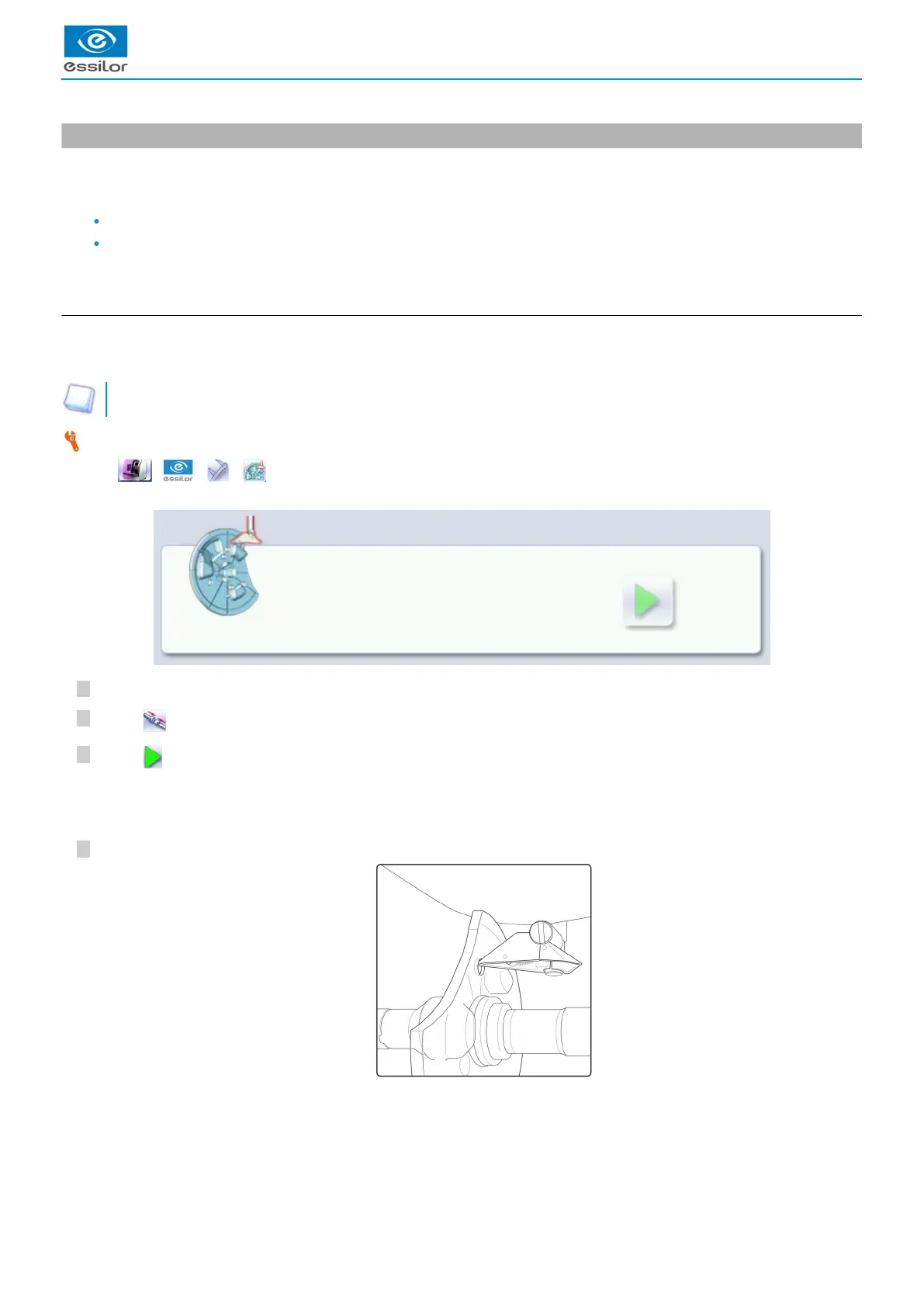

Place the calibration gauge in the posiblock holder.

Press to tighten the clamps.

Press to start the calibration cycle.

Check that the point of the feeler is positioned correctly.

The gauge is positioned at the level of the feeler, the feeler moves.>

Does a message appears “is the point of the feeler positioned correctly in the drill-hole of the plastic pattern?”>

Loading...

Loading...