7.1 Selecting Motors and Inverters

7-1

Chap. 7 SELECTING OPTIMAL MOTOR AND INVERTER CAPACITIES

7.1 Selecting Motors and Inverters

When selecting a general-purpose inverter, first select a motor and then inverter as follows:

(1) Key point for selecting a motor: Determine what kind of load machine is to be used, calculate its

moment of inertia, and then select the appropriate motor capacity

(2) Key point for selecting an inverter: Taking into account the operation requirements (e.g., acceleration

time, deceleration time, and frequency in operation) of the load machine to be driven by the motor

selected in (1) above, calculate the acceleration/deceleration/braking torque.

This section describes the selection procedure for (1) and (2) above. First, it explains the output torque

obtained by using the motor driven by the inverter (FRENIC-Mini).

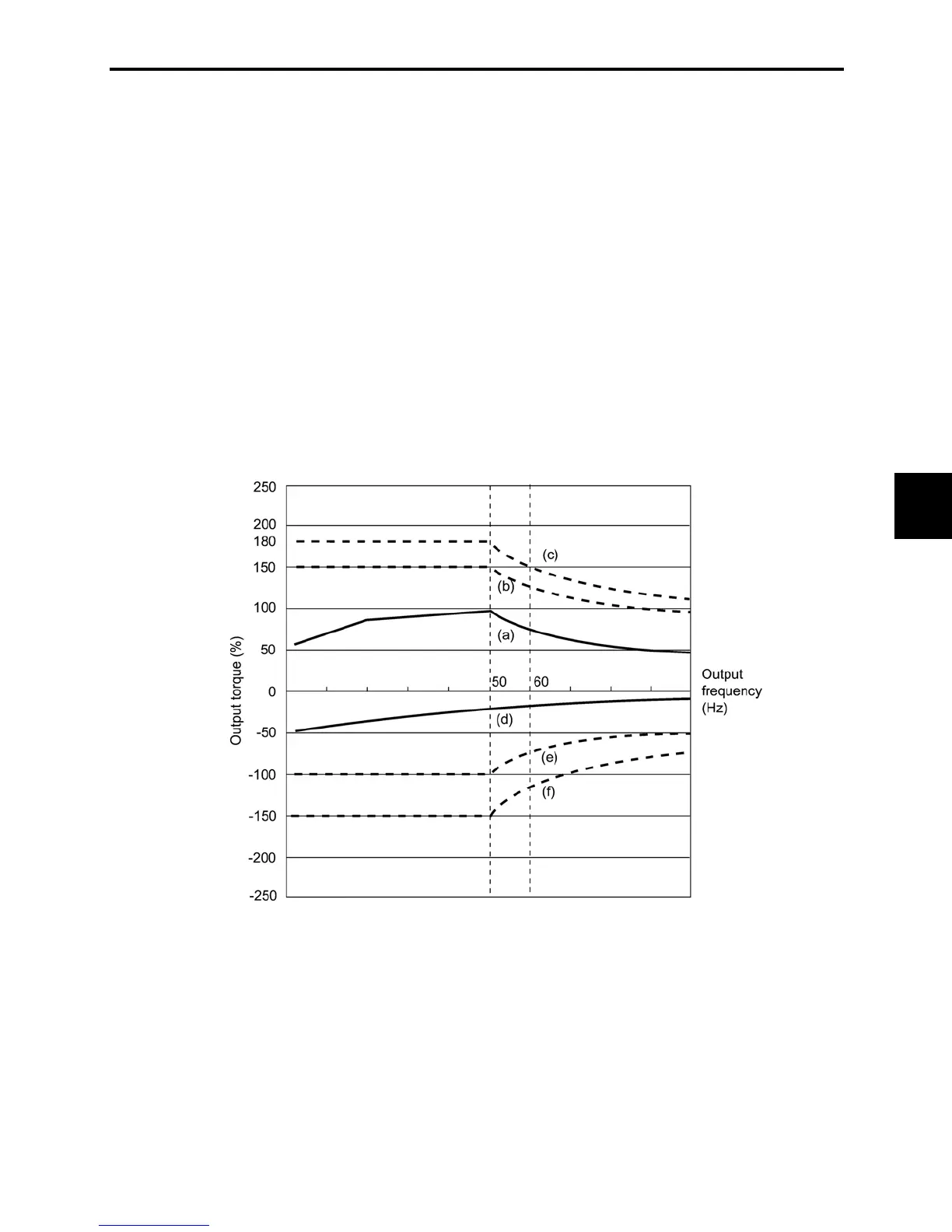

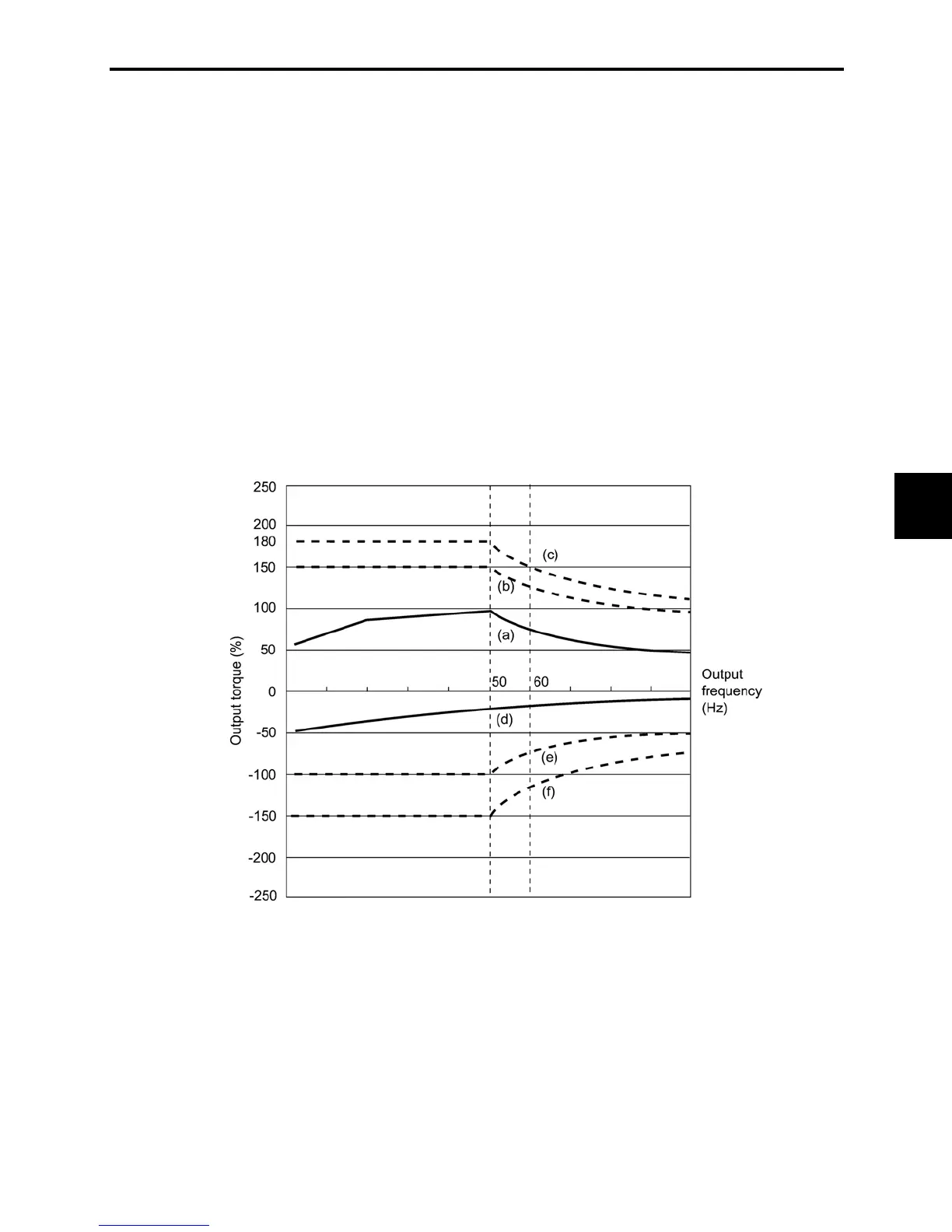

7.1.1 Motor output torque characteristics

Figures 7.1 and 7.2 graph the output torque characteristics of motors at the rated output frequency

individually for 50 Hz and 60 Hz base. The horizontal and vertical axes show the output frequency and

output torque (%), respectively. Curves (a) through (f) depend on the running conditions.

Figure 7.1 Output Torque Characteristics (Base frequency: 50 Hz)

Loading...

Loading...