7-10

(3) For a load running horizontally

Assume a carrier table driven by a motor as shown in Figure 7.7. If the table speed is X (m/s) when the

motor speed is N

M

(r/min), then an equivalent distance from the rotation axis is equal to 60·X / (2S·N

M

) m.

The moment of inertia of the table and load to the rotation axis is calculated as follows:

)mkg()WW()

N

ʌ2

ȣ60

(J

2

0

2

M

xx

x

x

(7.9)

[ 2 ] Calculation of the acceleration time

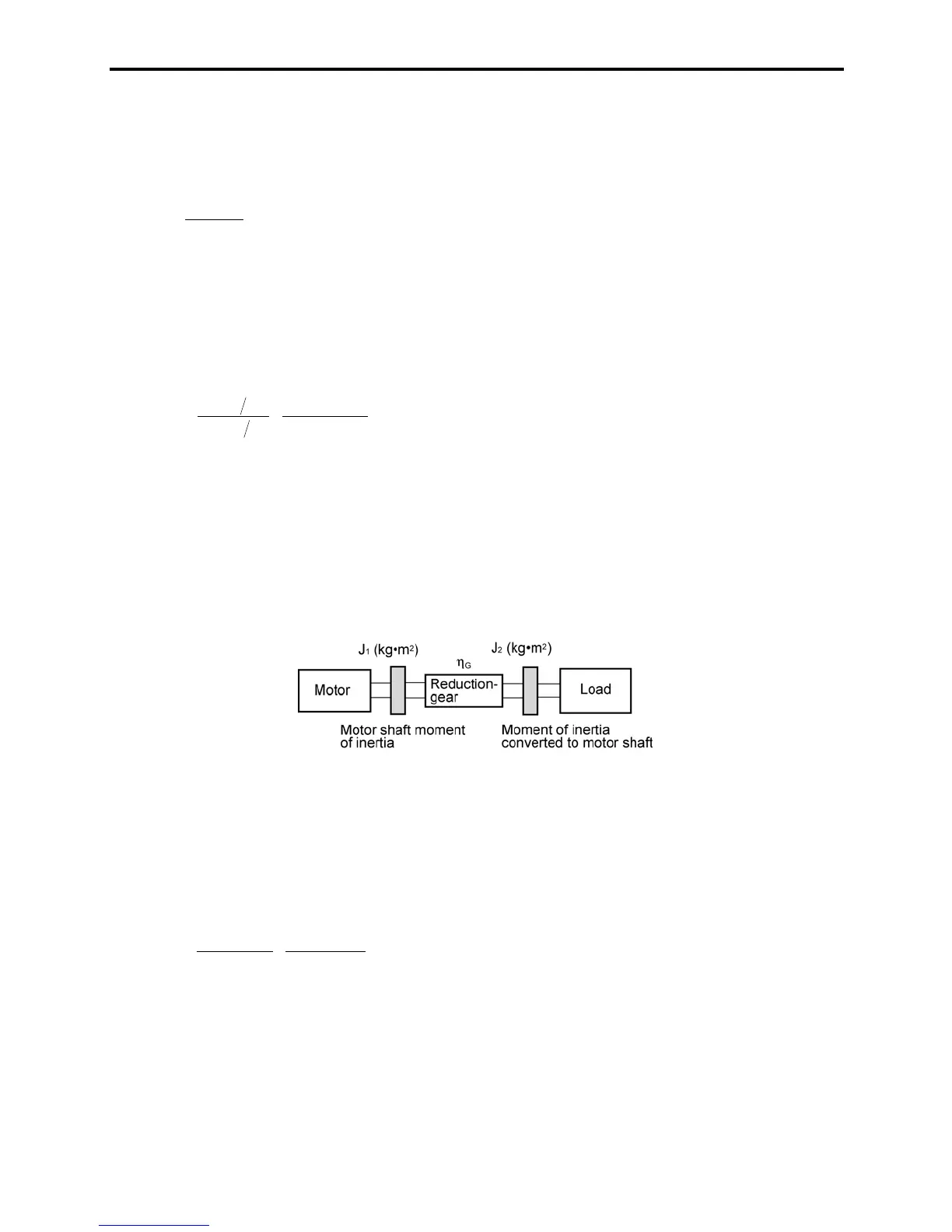

Figure 7.9 shows a general load model. Assume that a motor drives a load via a reduction-gear with

efficiency K

G

. The time required to accelerate this load to a speed of N

M

(r/min) is calculated with the

following equation:

)s(

60

)0

N

(2

JJ

t

M

G

LM

G

21

ACC

S

W

W

x

x

K

K

(7.10)

where,

J

1

: Motor shaft moment of inertia (kg·m

2

)

J

2

: Load shaft moment of inertia converted to motor shaft (kg·m

2

)

W

M

: Minimum motor output torque in driving motor (N·m)

W

L

: Maximum load torque converted to motor shaft (N·m)

K

G

: Reduction-gear efficiency.

As clarified in the above equation, the equivalent moment of inertia becomes (J

1

+J

2

/K

G

) by considering the

reduction-gear efficiency.

Figure 7.9 Load Model Including Reduction-gear

[ 3 ] Calculation of the deceleration time

In a load system shown in Figure 7.9, the time needed to stop the motor rotating at a speed of N

M

(r/min) is

calculated with the following equation:

)s(

60

)

N0

(2

JJ

t

M

G

LM

G

21

DEC

S

x

x

x

x

W

K

W

K

(7.11)

where,

J

1

: Motor shaft moment of inertia (kg·m

2

)

J

2

: Load shaft moment of inertia converted to motor shaft (kg·m

2

)

W

M

: Minimum motor output torque in braking (or decelerating) motor (N·m)

W

L

: Maximum load torque converted to motor shaft (N·m)

K

G

: Reduction-gear efficiency

In the above equation, generally output torque W

M

is negative and load torque W

L

is positive. So,

deceleration time becomes shorter.

Loading...

Loading...