Chapter 4 Disassembly / Assembly and Adjustment

4.1 Preface

4-3

4.1.2 Before starting service work

Start the procedure after turning off the power and removing the power cord from the outlet.

Wear an anti-static wrist band or the like whenever possible to remove static electricity of the human

body.

When removing parts, remove the XERO ASSY if necessary.

When performing the service operation around the FUSING UNIT, ensure that the FUSING UNIT

and its surrounding area have cooled down sufficiently.

Pay sufficient attention to the parts during the procedure because they may be broken or may cease

to function properly if unreasonable force is applied.

Put the removed parts such as TONER CARTRIDGE in a place where they do not affect the service

procedures. (Note that the service procedures can be performed with those parts in place depend-

ing on the target section of removal/replacement.)

Since various types of screws are used, ensure that the right screws are used in their right positions.

Use special caution not to confuse the screws for plastic and the ones for sheet metal, because

using the wrong type of screws may result in damage to the screw threads or other troubles.

At the locations with "TAP" marked on the base material and sheet metal, use tap screws for plastic.

Screws you should not loosen are used the special screw.

Never loosen the special screws because the equipment may not operate correctly.

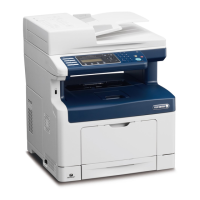

No. Type Application Shape How to distinguish

Points to be

noted

1

Screw for

plastic

Silver, tap

Plastic

Silver-colored

・

Thread is coarser

than that of the

sheet metal type.

・

Screw tip is thin.

Oblique screw-

ing damages the

thread because

this screw cuts

female threads

in the base

material as it

goes in.

2

Screw for

metal sheet

Silver

Sheet metal

・

Silver-colored

・

Diameter of the

thread section is

uniform.

Loading...

Loading...