12 - Monitoring Parameters

Code Parameter Name / Range

12-00 Display screen selection (LED)

Highest

digit => 0 0 0 0 0 <= lowest digit

The value range of each digit is 0~7 from the highest to the lowest,

0: Default display (frequency¶meters)

1: Output current

2: Output voltage

3: DC bus voltage

4: Heatsink temperature

5: PID feedback

6: Analog Signal Input. (AVI)

7: Analog Signal Input. (ACI)

Note: The highest bit is used for power-up monitor. The 4 least significant bits can be used to customize the display se-

quence see chapter 4.1.3.

Code Parameter Name / Range

12-01 PID feedback display mode (LED)

0: Display the feedback value in integer (xxx)

1: Display the feedback value with one place after the decimal point (xx.x)

2: Display the feedback value (x.xx) with two places after the decimal point

12-02 PID feedback display unit setting (LED)

0: xxxxx (no unit)

1: xxxPb (pressure)

2: xxxFL (flow)

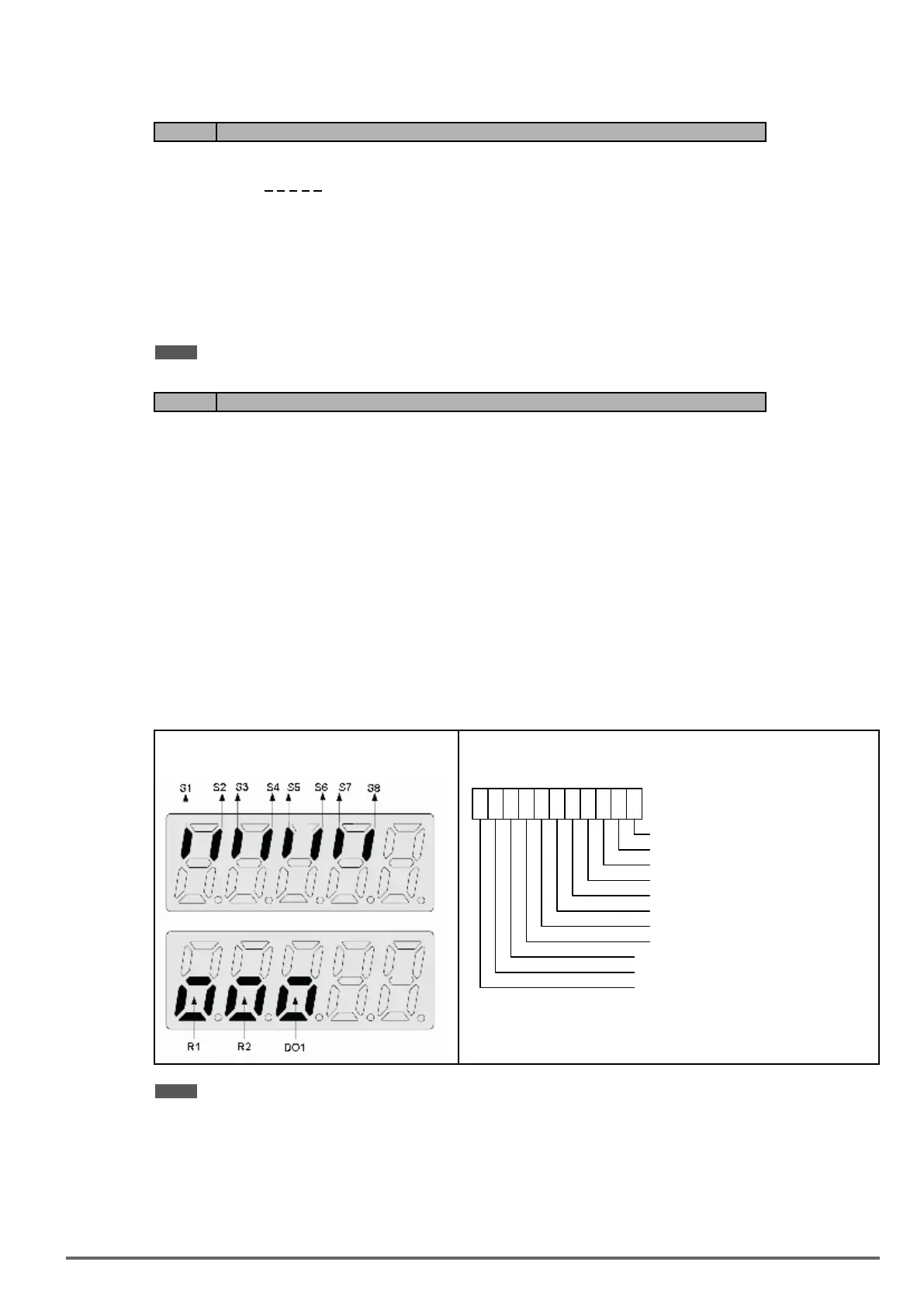

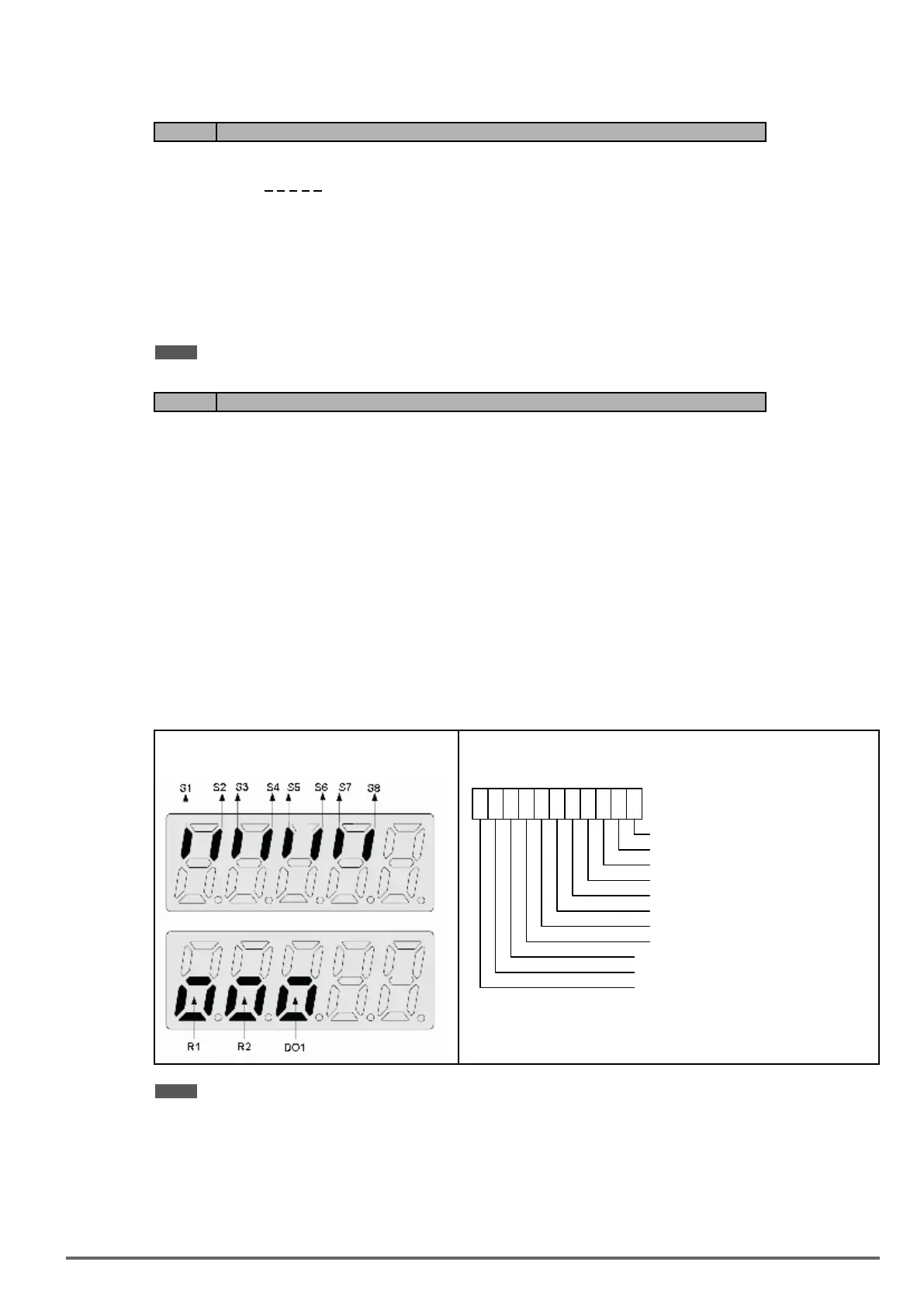

12-05 Status display of digital input terminal (LED / LCD)

Read-only

Terminals S1-S8 are represented using two segments of each digit. Segment turns on when input is active.

The bottom segments of each of the rst three digits are used to represent the digital outputs (R1, R2, DO1).

Segments turn on when output is active.

Example1:

S1~S8, R1, R2 and DO1 are ON

Example 2:

S1~S8, R1, R2 and DO1 are OFF

00 00 00 0 0

Input Terminal(S8)

Input Terminal(S7)

Input Terminal(S6)

Input Terminal(S5)

Input Terminal(S4)

Input Terminal(S3)

Input Terminal(S2)

Input Terminal(S1)

0: OPEN

1: CLOSE

000

Output Terminal(DO1)

Output Terminal(R2)

Output Terminal(R1)

Note: Refer to section 4.3 for monitors 12-11~12-64.

Monitoring parameter 12-66: Encoder Angle

Encoder PG pulse (20-27) is set to correct connection with the encoder wiring. Make the motor rotate forwardly

at non-run state and the angle will accumulate to 360°at two times; if make the motor rotate reversely, the angle

will regress to 360° at two times.

Monitoring parameter 12-67: Cumulative Energy (kWHr) & 12-68: Cumulative Energy (MWHr)

VDI100 • Instruction manual 239

Loading...

Loading...