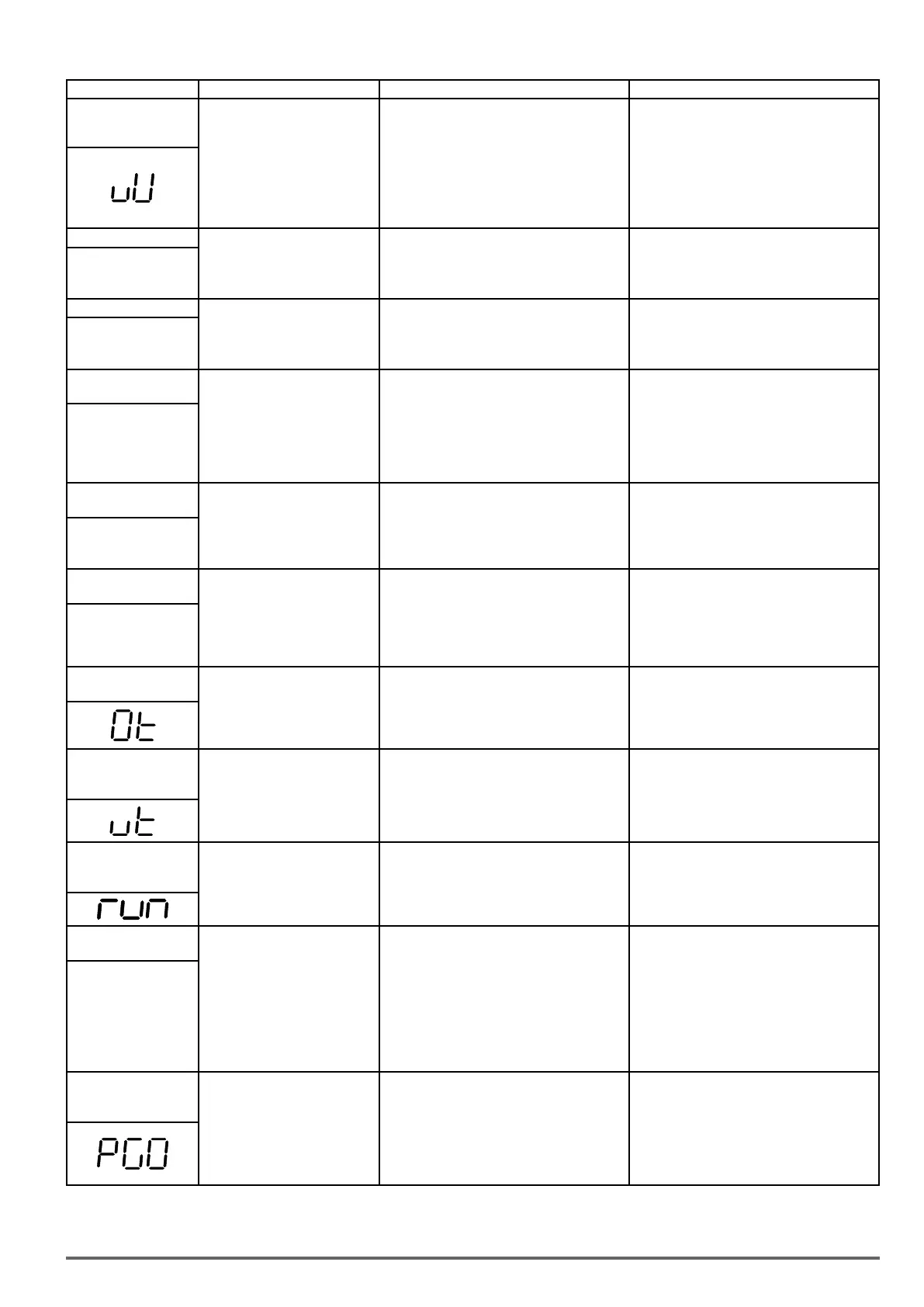

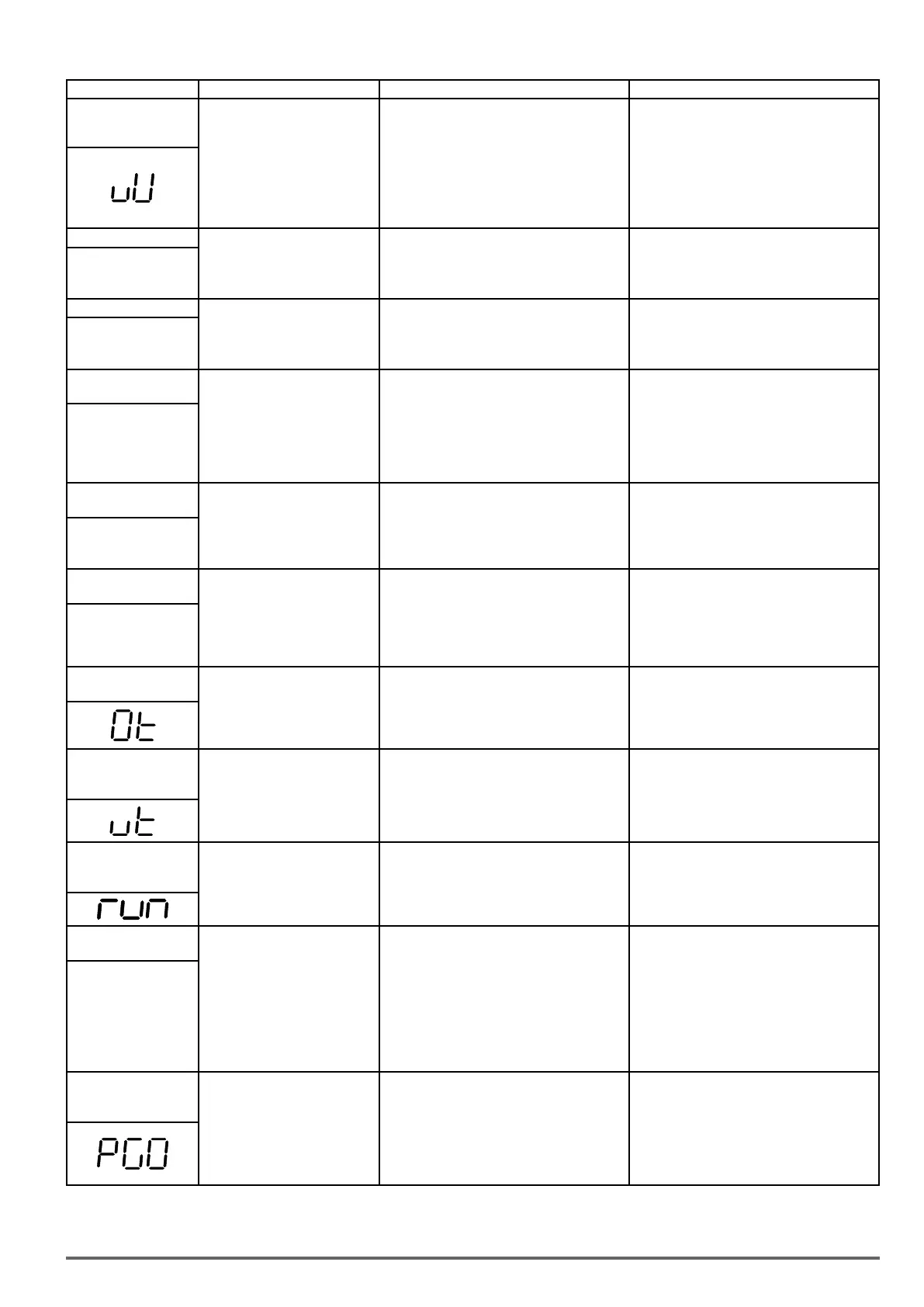

LED display Description Cause Possible solutions

UV

Under voltage

DC bus voltage is lower than

the UV detection level or the

pre-charge contactor is not active

while the inverter is running.

190Vdc: 230V class;

380Vdc: 460V

class

(The detection value can be

adjusted by 07-13).

• The input voltage is too low.

• Input phase loss.

• Acceleration time set too short.

• Input voltage fluctuation.

• Pre-charge contactor damaged.

• DC bus voltage feedback signal value not

incorrect.

• Check the input voltage.

• Check input wiring.

• Increase acceleration time.

• Check power source

• Replace pre-charge contactor

• Replace control board or complete inverter.

IPL input phase loss

Phase loss at the input side of

the inverter or input voltage

imbalance, active when 08-09 =

1 (enabled)

• Wiring loose in inverter input terminal.

• Momentary power loss.

• Input voltage imbalance.

• Check input wiring / faster screws.

• Check power supply

IPL

OPL output phase loss

Phase loss at the output side of

the inverter, active when 08-10 =

1 (enabled).

• Wiring loose in inverter output terminal.

• Motor rated current is less than 10% of the

inverter rated current.

• Check output wiring / faster screws.

• Check motor & inverter rating.

OPL

OH1

Heatsink overheat

The temperature of the heat sink

is too high.

Note: when OH1 fault occurs

three times within five minutes,

it is required to wait 10 minutes

before resetting the fault.

•Ambient temperature too high.

• cooling fan failed

• Carrier frequency set too high.

• Load too heavy.

•Install fan or AC to cool surroundings.

•Replace cooling fan.

•Reduce carrier frequency.

•Reduce load / Measure output current

OHI

OL1

Motor overload

Internal motor overload protection

tripped, active when protection

curve 08-05 = xxx1.

•Voltage setting V/f mode too high, resulting in

over-excitation of the motor.

•Motor rated current (02-01) set incorrectly.

•Load too heavy.

•Check V/f curve.

•Check motor rated current

•Check and reduce motor load, check and

operation duty cycle.

OLI

OL2

Inverter overload

Inverter thermal overload pro-

tection tripped.

If an inverter overload occurs 4 ti-

mes in five minutes, it is required

to wait 4 minutes before resetting

the fault.

• Voltage setting V/f mode too high, resulting

in over-excitation of the motor.

• Inverter rating too small.

• Load too heavy.

•Check V/f curve.

•Replace inverter with larger rating.

•Check and reduce motor load, check and

operation duty cycle.

OL2

OT

Over torque detection

Inverter output torque is higher

than 08-15 (over torque detection

level) for the time specified in

08-16. Parameter 08-14 = 0 to

activate.

• Load too heavy.

• Check over torque detection parameters (08-

15 / 08-16).

• Check and reduce motor load, check and

operation duty cycle.

UT

Under torque

detection

Inverter output torque is lower

than 08-19 (under torque detec-

tion level) for the time specified

in 08-20. Parameter 08-18 = 0 to

activate.

•Sudden drop in load.

•Belt break.

•Check under torque detection parameters

(08-19 / 08-20).

•Check load / application.

run

Switch for Motor1/

Motor2

Switch for Motor1/Motor2 in

running time

• Execute command for switching motor2 in

running time

• Execute command for switching motor in

running time

•Revise the sequence control and switch motor

in top time.

OS

Over speed

Motor speed exceeds level set

in 20-20 (PG Over speed Level)

for the time set in 20-21 (PG over

speed time). Active when 20-19

(= 0 or 1).

This fault is active V/f + PG and

SV control mode (00-00 = 1

or 3 or 4). Motor speed can be

monitored by 12-22

•Motor speed overshoot (ASR)

•PG ppr set incorrectly.

•Overspeed parameters set incorrectly.

•Check ASR parameters group 21.

•Check PG parameters

•Check overspeed parameters 20-20/20-12

O5

PGO

PG

Open circuit

PG pulses are not received by the

inverter for the time specified in

20-26 (PG open circuit detection

time).

This fault is active V/f + PG and

SV control mode (00-00 = 1 or

3 or 4).

•PG cable disconnected.

•PG has no power.

•Mechanical brake active preventing motor

from turning.

•Check PG wiring.

•Check PG power-supply.

•Make sure brake is released.

VDI100 • Instruction manual 331

Loading...

Loading...