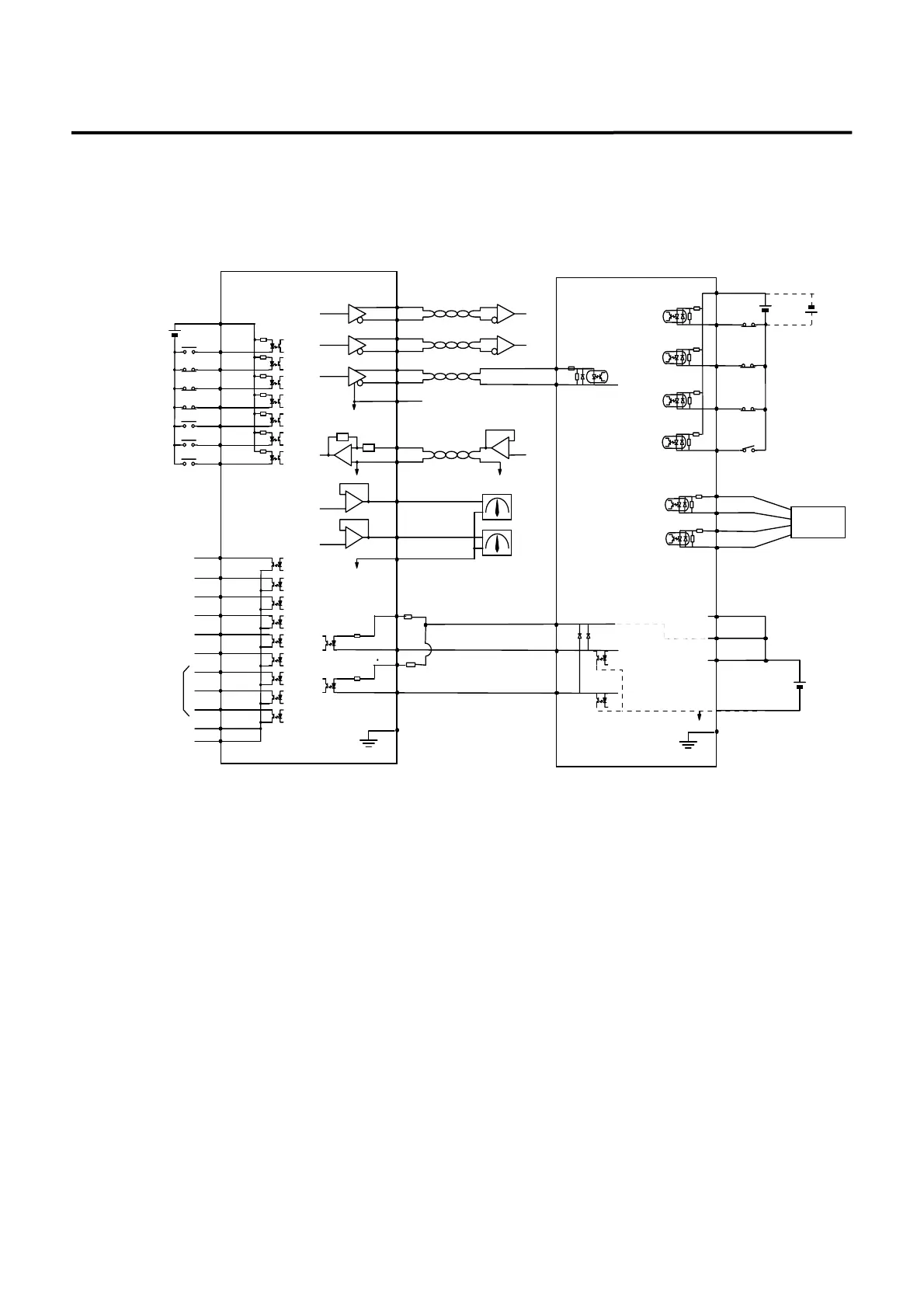

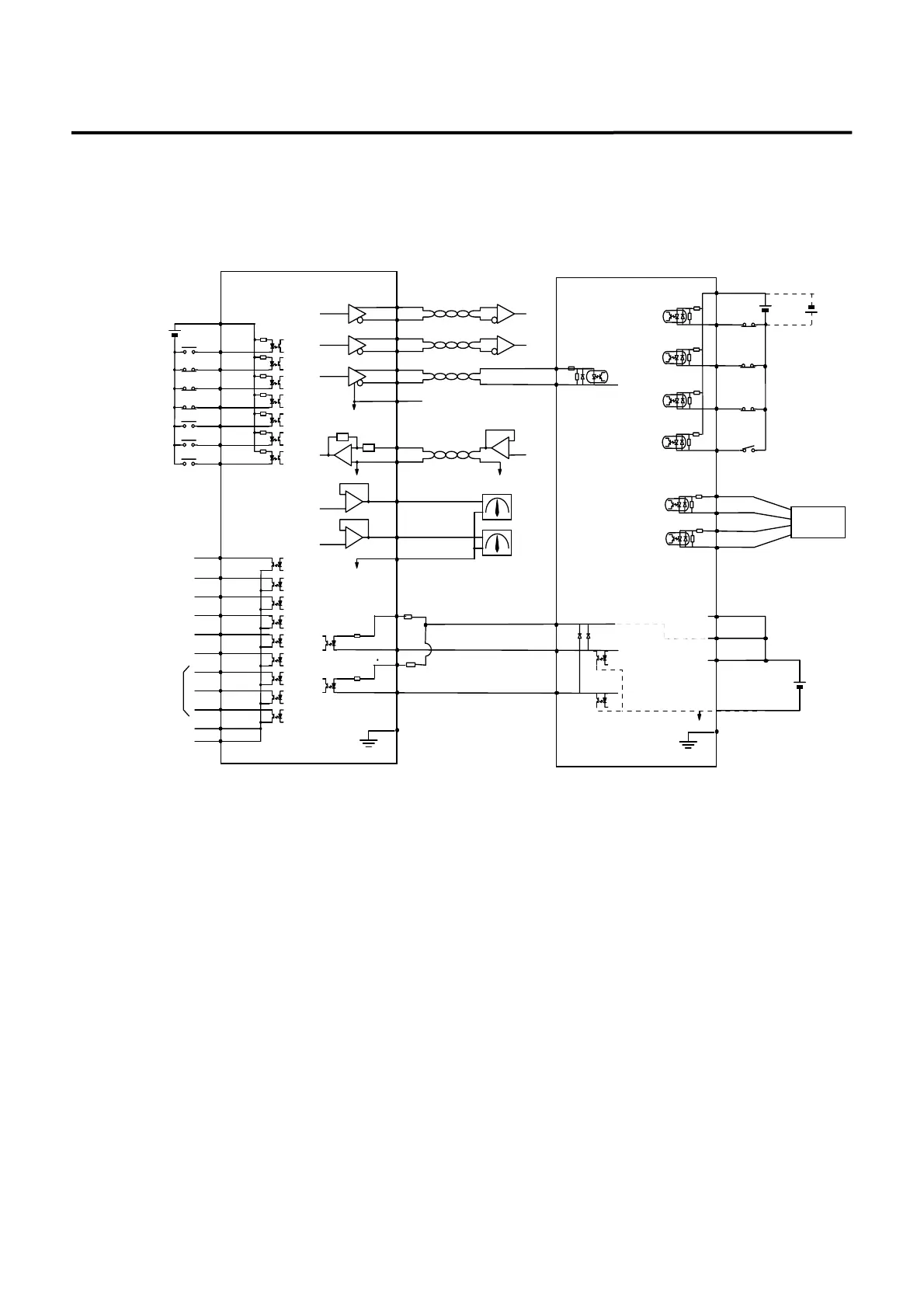

Chapter 13. Examples of Operation Flow and PLC Wiring

13-3

13.5 Example of positioning Unit K7F-POSP connection between FDA-5000,

the AC servo driver of HIGEN and PLC MASTER-K

*2 : USE CN1 shield wire to groung the F.G(Frame Ground) terminal

Manual pulse

DC 5V ~ 12V

1

4

5

10

24V GND

+24V

24V COM

24 COM

7

16

8

9

MPGA

MPGA-C

MPGB

MPGB-C

22

19

18

3

2

ICOM

UpperL/S

Lower L/S

Emergency

stop

Origin L/S

DC 24V

DC 24V

11

2

4,5

24 COM

FP

RP

6

FG

MASTER-K (K7F - POSP)

ZL

ZCOM

25

15

/PAO

PAO (7)

(32)

/PBO

PBO

(6)

(31)

/PZO

PZO (5)

(30)

GND [*1]

*1 : Use GND terminal from among 1,8,26,33,34,36

-

+

-

+

MONIT1

MONIT2

(3)

(2)

TRQIN

(28)

GND

[*1]

-

+

-

+

GND

[*1]

10k

0~5V

0~5V

PPFIN

(10)

PFIN

PRIN

(9)

(12)

F.G (50)

[*2]

10k

Speed

Torque

0~10V

CN1 of FDA-5000

PPRIN

(11)

SVONEN(18)

(38)

ALMRST

CLR

(41)

PI/P

(14) TLIM

(15) CCWLIM

(40) CWLIM

(39)

ESTOP

24[V]

+24VIN(49)

Servo enable

CCW limit

CW limit

Emergency stop

Alarm reset/

Cumulative pulse clear

Select PI/P control

Analog torque limit

avaliable

(24) GND24

(25) GND24

A_CODE0

A_CODE1

A_CODE2

(45)

(44)

(19)

0 SPD(47)

ALARM(20)

INPOS(22)

(21) RDY

BRAKE(48)

Servo ready

In position

Zero speed

Brake activate

Alarm status

Alarm code

TLQOUT

(46)

1/2W 1.5K

1/2W 1.5K

Torque under limit

-4 ~ +4V

-4 ~ +4V

-10 ~ +10V

.

Loading...

Loading...