Chapter 1. Checking and Handling

1-2

1.2 Caution during Use

Improper handling of the driver may lead to unexpected accident or damage. The following are

important points in operating the driver.

1.2.1 Handling

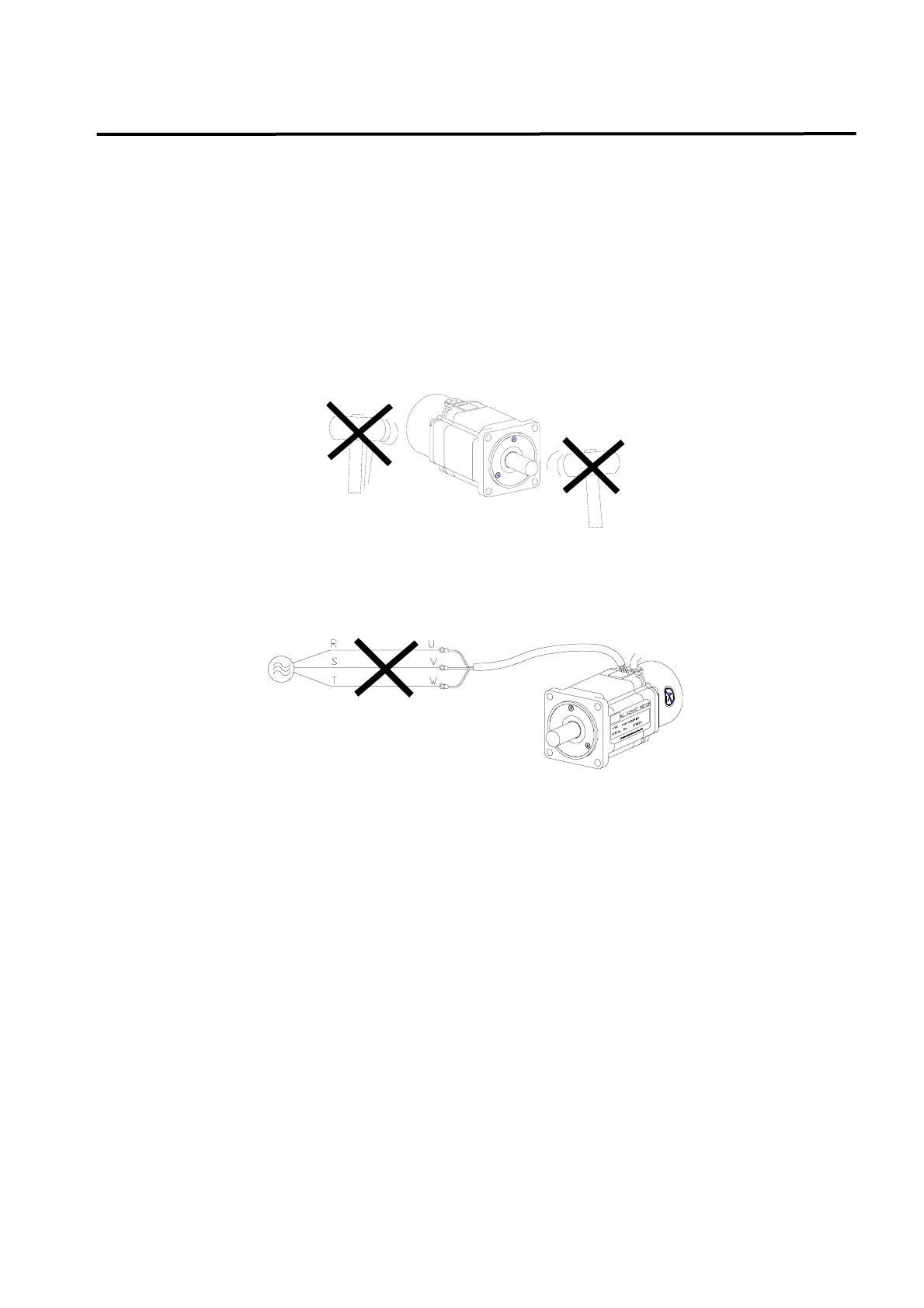

y Avoid impact to the encoder, the motor detector.

Striking the shaft with a hammer may cause the motor to drop leading to unexpected damage.

y Do not connect commercial power supply (AC 220V) directly to the motor.

Direct connection induces flow of overcurrent leading to the deterioration of the magnetic effect.

Always use specified servo driver.

1.2.2 Wiring

y Connect the driver and the motor earth terminals in the direction of the driver, and ground the

terminals at the shortest distance in one operation. To prevent electric shock and improper

operation, use class-3 earth (Less than 100 Ω).

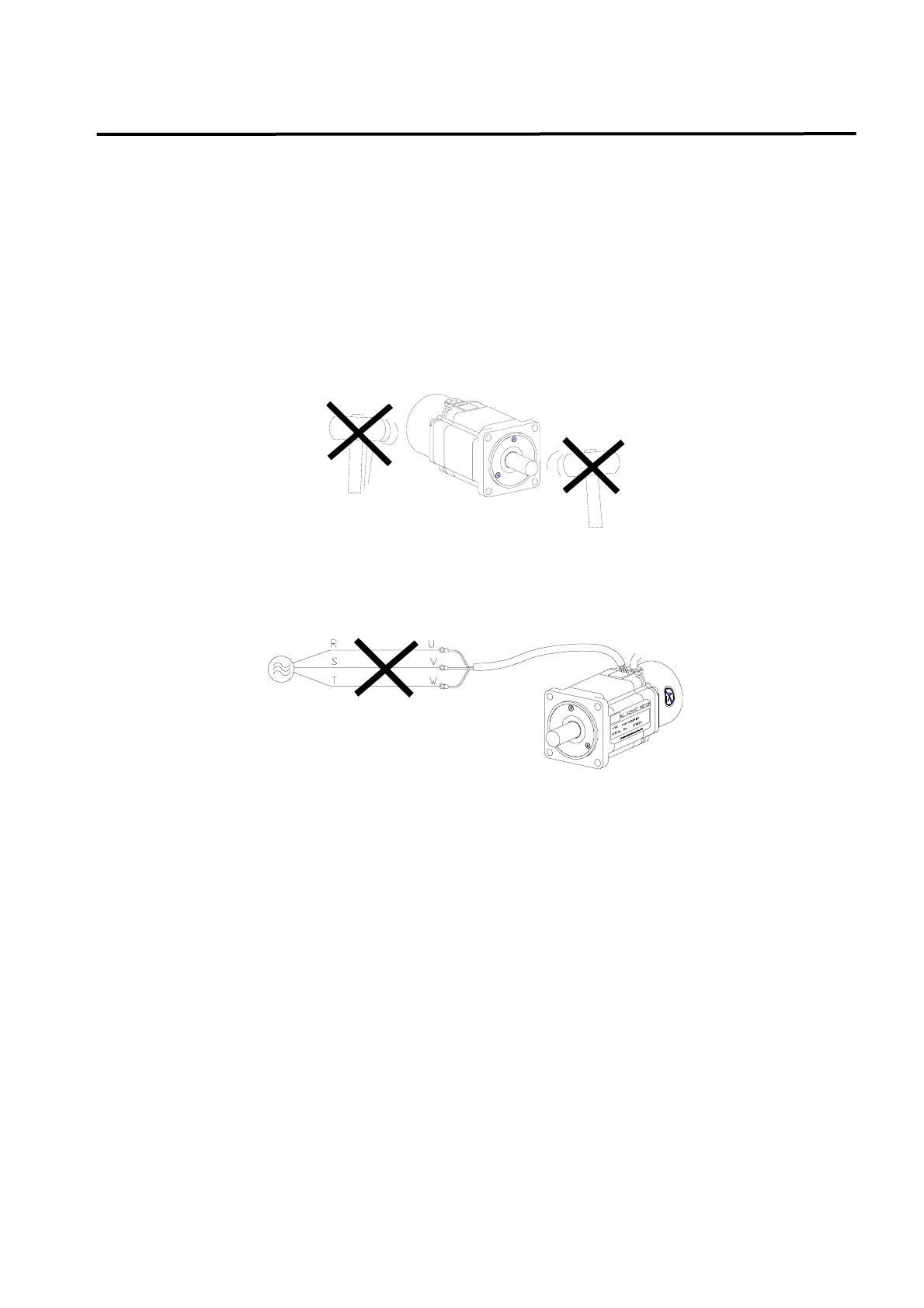

y Always match the U, V ,W and FG terminals of the motor with those of the driver. You cannot

change the direction of rotation by changing 2 wires as in the case of widely used common

motors.

y Connecting commercial power supply to the U, V, W and FG terminals of the driver may cause

damage.

(Apply 200V power supply to R, S and T terminals)

Use a transformer in case power supply is other than 200V.

y Connect standard regenerated resistance to the P and B terminals of the driver.

Loading...

Loading...