LUBRICATION SYSTEM

5-5

OIL PRESSURE CHECK

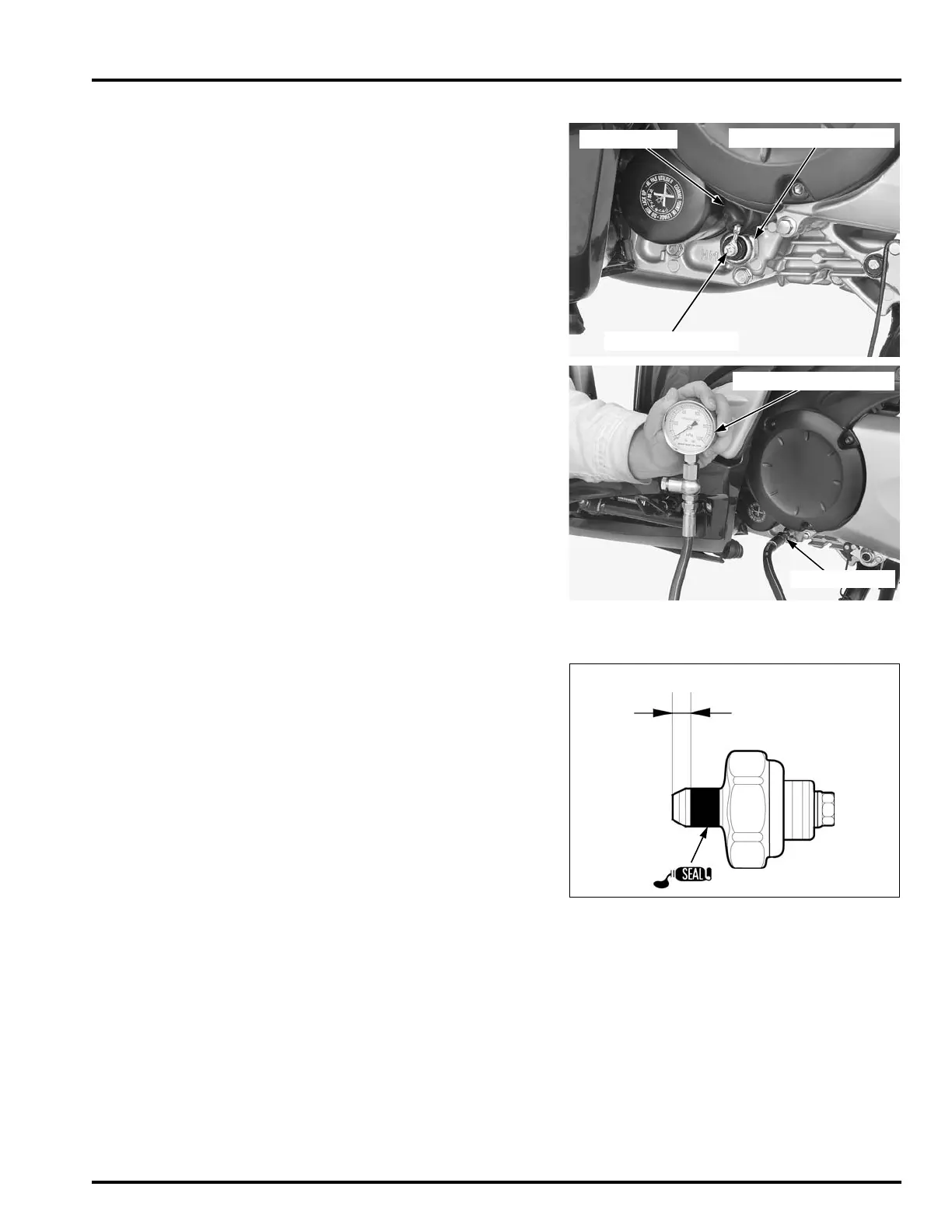

Remove the right floor side cover (page 3-8).

If the engine is cold, the pressure reading will be

abnormally high. Warm up the engine to normal

operating temperature before starting this test.

Stop the engine.

Slide the rubber cap off and disconnect the oil pres-

sure switch wire by removing the terminal screw.

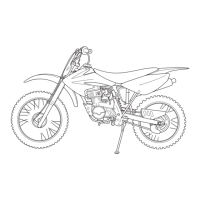

Remove the oil pressure switch and connect an oil

pressure gauge attachment and gauge to the pres-

sure switch hole.

Check the oil level and add the recommended oil if

necessary (page 4-10).

Start the engine and check the oil pressure at 5,000

min

-1

(rpm).

Stop the engine.

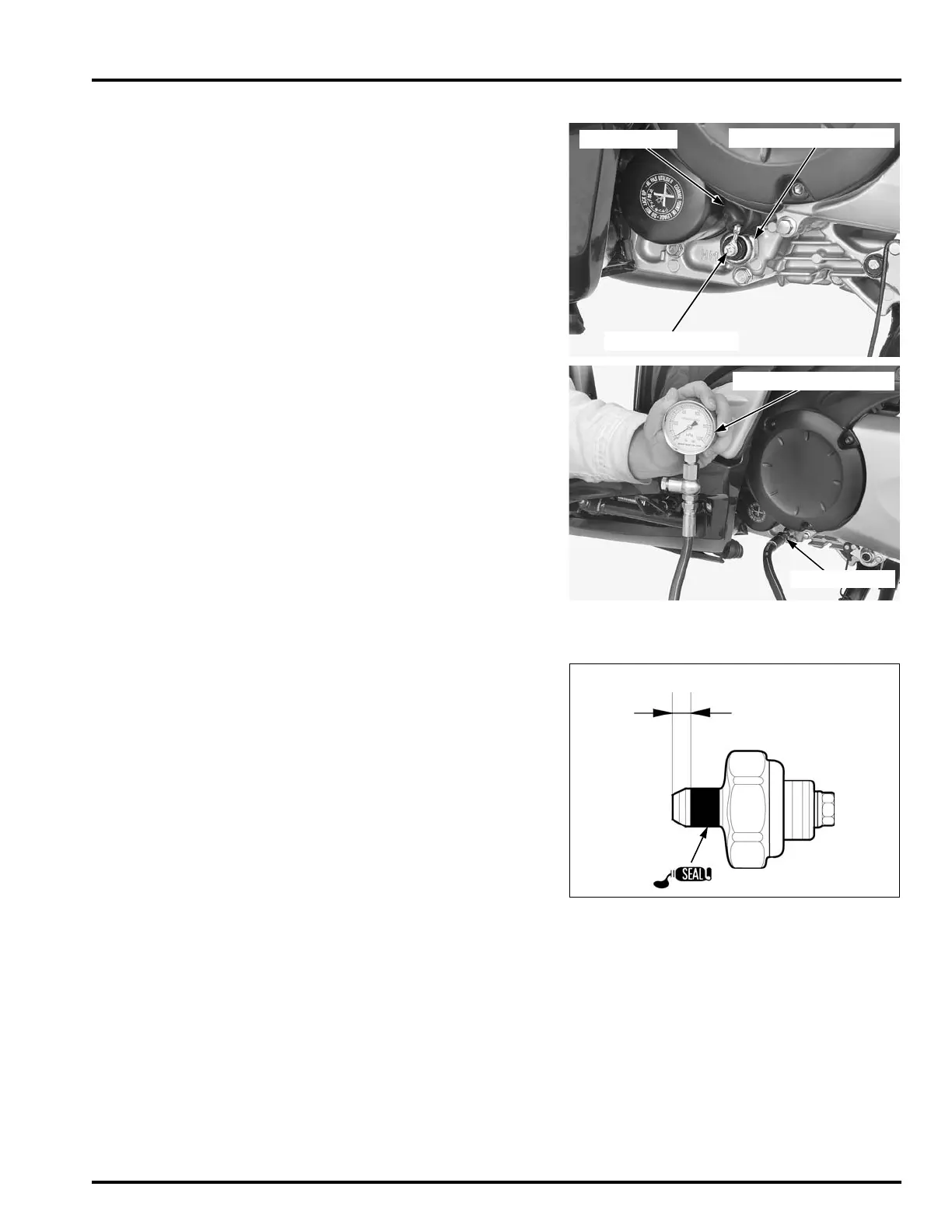

Do not apply seal-

ant to the thread

head 3 – 4 mm (0.1

– 0.2 in).

Apply sealant (Three Bond 1207B or equivalent) to

the oil pressure switch threads as shown and

tighten it to the specified torque.

Connect the oil pressure switch wire and tighten the

terminal screw.

Install the rubber cap.

Start the engine.

Check that the oil pressure indicator turns off after 1

or 2 seconds. If the oil pressure indicator stays on,

stop the engine immediately and determine the

cause (page 22-15).

RUBBER CAP

TERMINAL SCREW

OIL PRESSURE SWITCH

TOOLS:

Oil pressure gauge set 07506-3000001

Oil pressure gauge attachment 07406-0030000

or equivalent commercially available

OIL PRESSURE:

530 kPa (5.4 kgf/cm

2

, 77 psi) at 5,000 min

-1

(rpm)

(80°C/176°F)

OIL PRESSURE GAUGE

ATTACHMENT

TORQUE: 12 N·m (1.2 kgf·m, 9 lbf·ft)

Loading...

Loading...