Loading...

Loading...

Do you have a question about the Inovance Monarch 220-NICE-L-C-4022F and is the answer not in the manual?

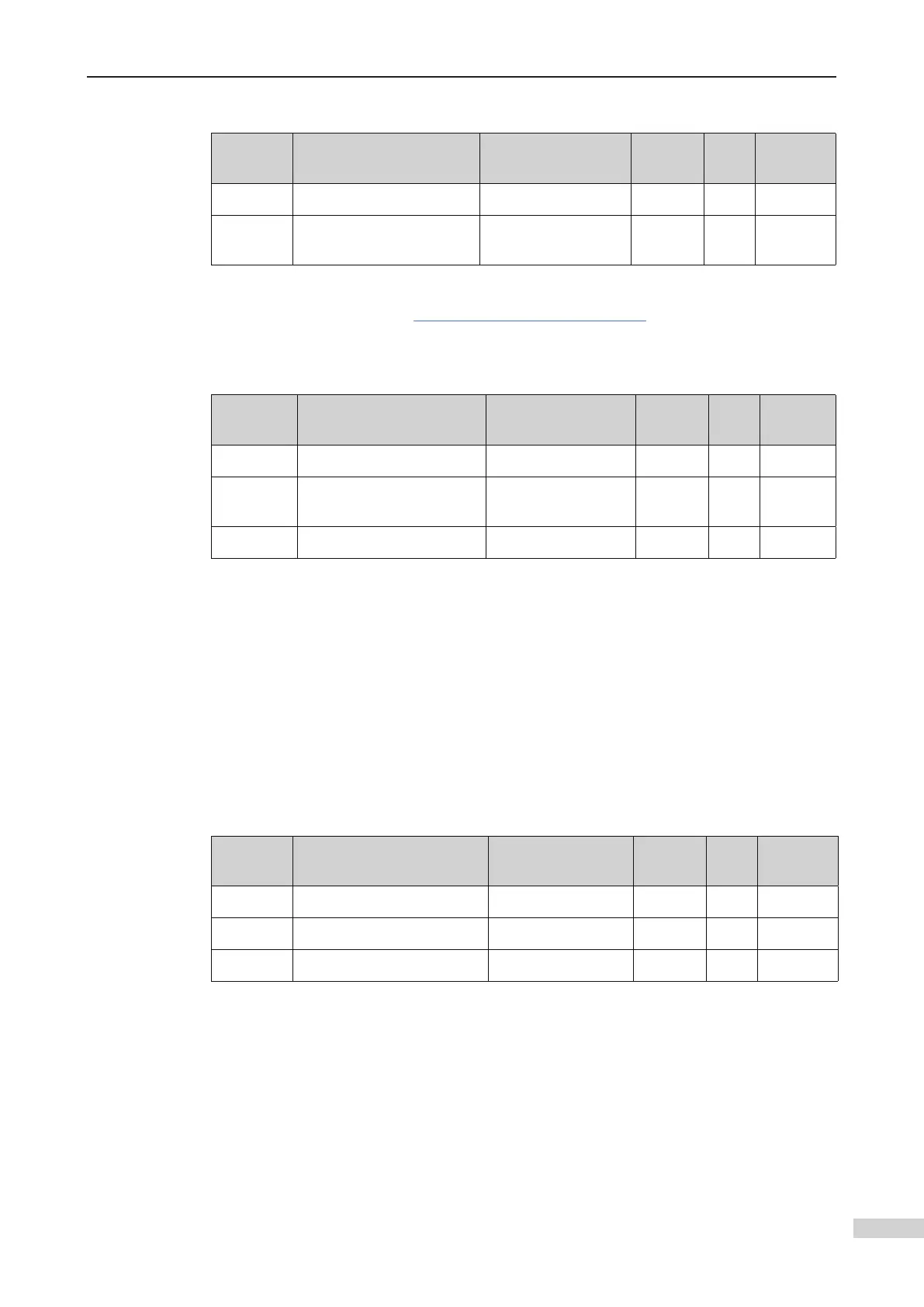

| Product name | Inovance Monarch 220-NICE-L-C-4022F |

|---|---|

| Model | 220-NICE-L-C-4022F |

| Rated voltage | 220V |

| Control mode | Vector control |

| Application | Industrial automation |

| Output Current | 2.2 A |

| Control Method | V/F control, Sensorless vector control |

| Communication Interface | Modbus RTU |

| Protection Features | Overcurrent, Overvoltage, Overheat, Short circuit |

| Humidity | 5% to 95% (non-condensing) |

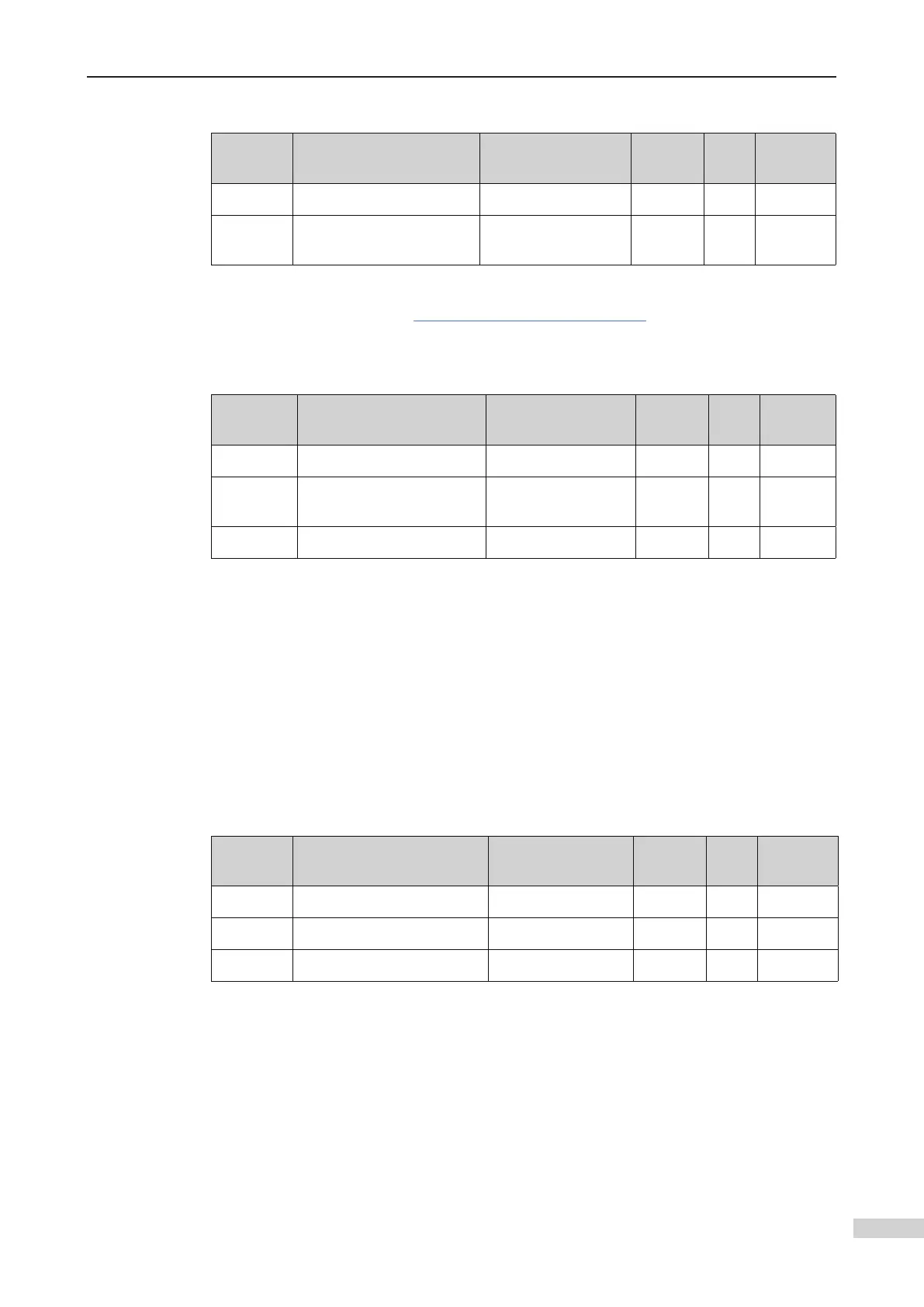

Details the advanced technological features of the NICE3000new controller, including drive ride and communication.

Focuses on safety features, fault tolerance, and environmental adaptability for secure operation.

Details fundamental functionalities like collective selective operation, service floor settings, and door control.

Explains the model designation rules and details found on the controller's nameplate.

Provides an overview of the physical components of the controller, illustrating their locations.

Illustrates the system components and their interconnections for the NICE3000new control system.

Covers installation requirements, including environment, clearance, orientation, dimensions, and procedures.

Describes the description and wiring of main circuit and control circuit terminals, including cable sizes.

Provides wiring diagrams and inspection checklists for the entire system setup.

Offers guidance on selecting cables, circuit breakers, contactors, reactors, and filters.

Provides a general guide to the commissioning process for the elevator system.

Details crucial safety precautions and checks required before performing system commissioning.

Covers procedures for checking power-on status and handling potential controller states and faults.

Explains the process of motor auto-tuning and running tests at inspection speed.

Outlines steps for commissioning at normal speed, including shaft auto-tuning and HCB setup.

Explains how fault codes and subcodes are displayed on the keypad and operation panel.

Provides a table linking fault codes to possible causes and recommended solutions for troubleshooting.

Details how the system provides emergency evacuation during power failures using UPS or ARD.