ENGINE ASSEMBLY ( 3 )

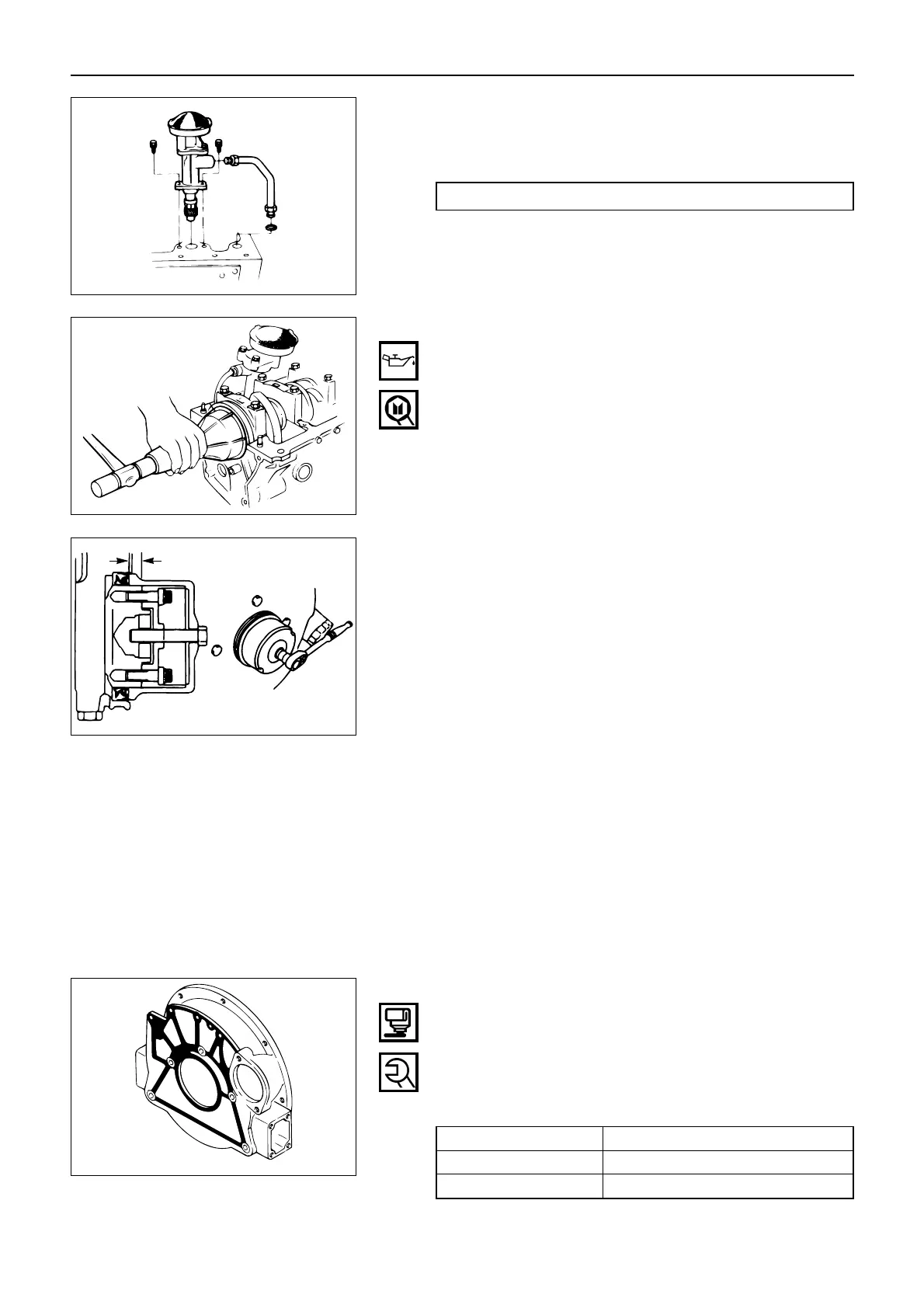

12. Oil Pump with Oil Pipe

Install the oil pump with the oil pipe and tighten the

bolts to the specified torque.

Oil Pump Bolt Torque kgf·m(lb.ft/N·m)

1.4 – 2.4 (10.1 – 17.3/13.7 – 23.5)

Note:

Take care not to damage the O-rings when tightening

the oil pipe bolts.

13. Crankshaft Rear Oil Seal

1) Apply engine oil to the oil seal lip circumference

and the oil seal outer circumference.

2) Use the oil seal installer to install the oil seal to

the cylinder body.

Oil Seal Installer: 5-8840-0141-0

13. Crankshaft Rear Oil Seal (Axial Type)

1) Tighten the adapter to the crankshaft rear and

section with 2 bolts.

2) Insert the oil seal into the peripheral section of

adapter.

3) Insert the sleeve into the adapter section, and 1)

tighten it with a bolt (M12 x 1.75L = 70) until the

adapter section hits the sleeve.

4) Remove the adapter and the sleeve.

5) With the seal pressed in, check the dimension of

the oil seal section.

Standard Dimension = 12.5 ± 0.3 mm

(0.492 ± 0.012 in)

Oil Seal Installer: 5-8840-9057-0

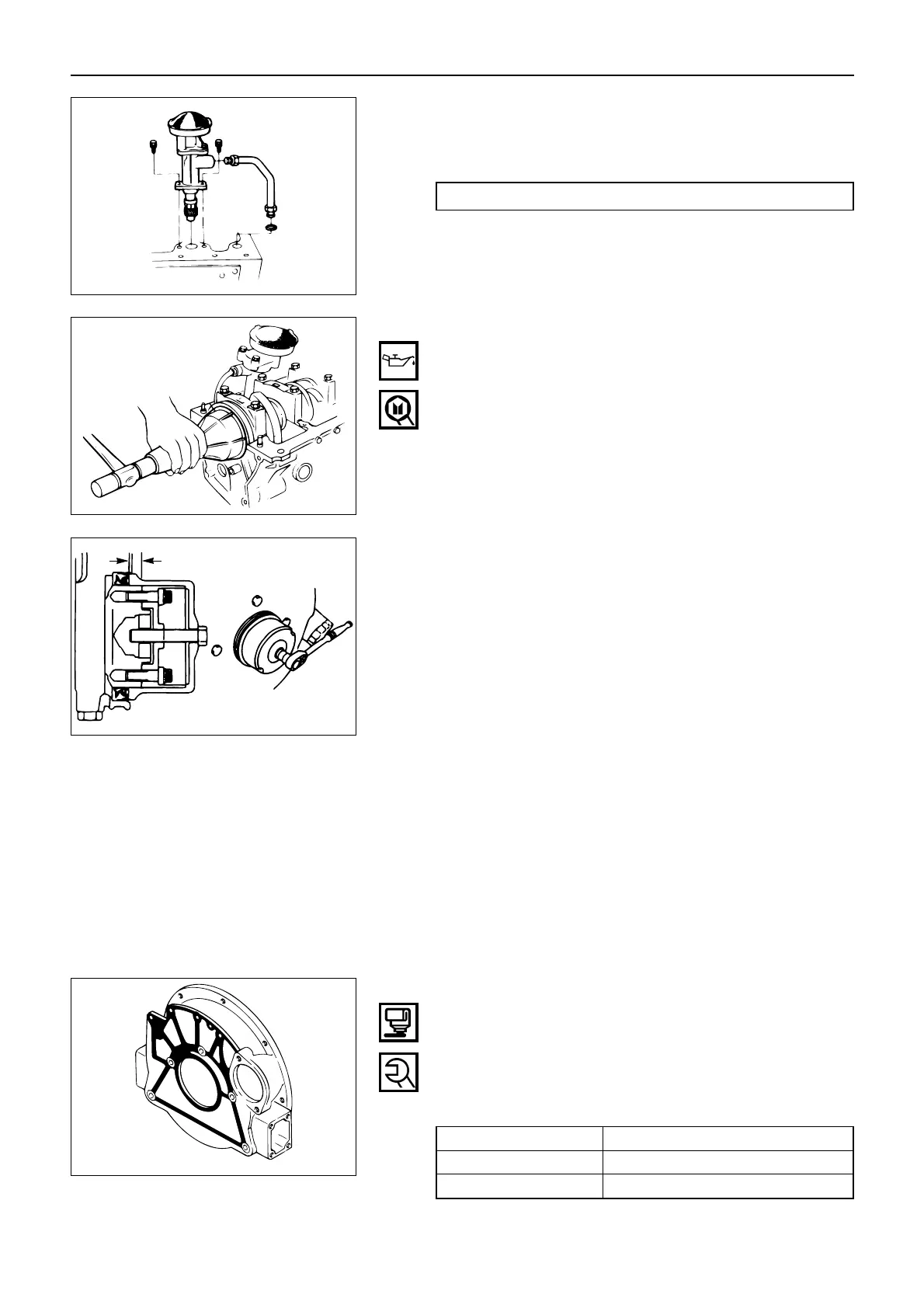

14. Flywheel Housing

1) Apply sealant to the shaded area shown in the

illustration.

2) Tighten the flywheel housing bolts to the speci-

fied torque a little at a time in the sequence

shown in the illustration.

Flywheel Housing Bolt Torque kgf·m(lb.ft/N·m)

M10x1.25 (0.39x0.05) 4.6 – 6.6 (33.3 – 47.7/45.1 – 64.7)

M12x1.25 (0.47x0.05) 9.6 – 11.6 (69.4 – 83.9/94.1 – 113.8)

M12x1.75 (0.47x0.07) 8.8 – 10.8 (63.7 – 78.1/86.3 – 105.9)

Loading...

Loading...