ENGINE ASSEMBLY ( 2 )

FLYWHEEL AND RING GEAR

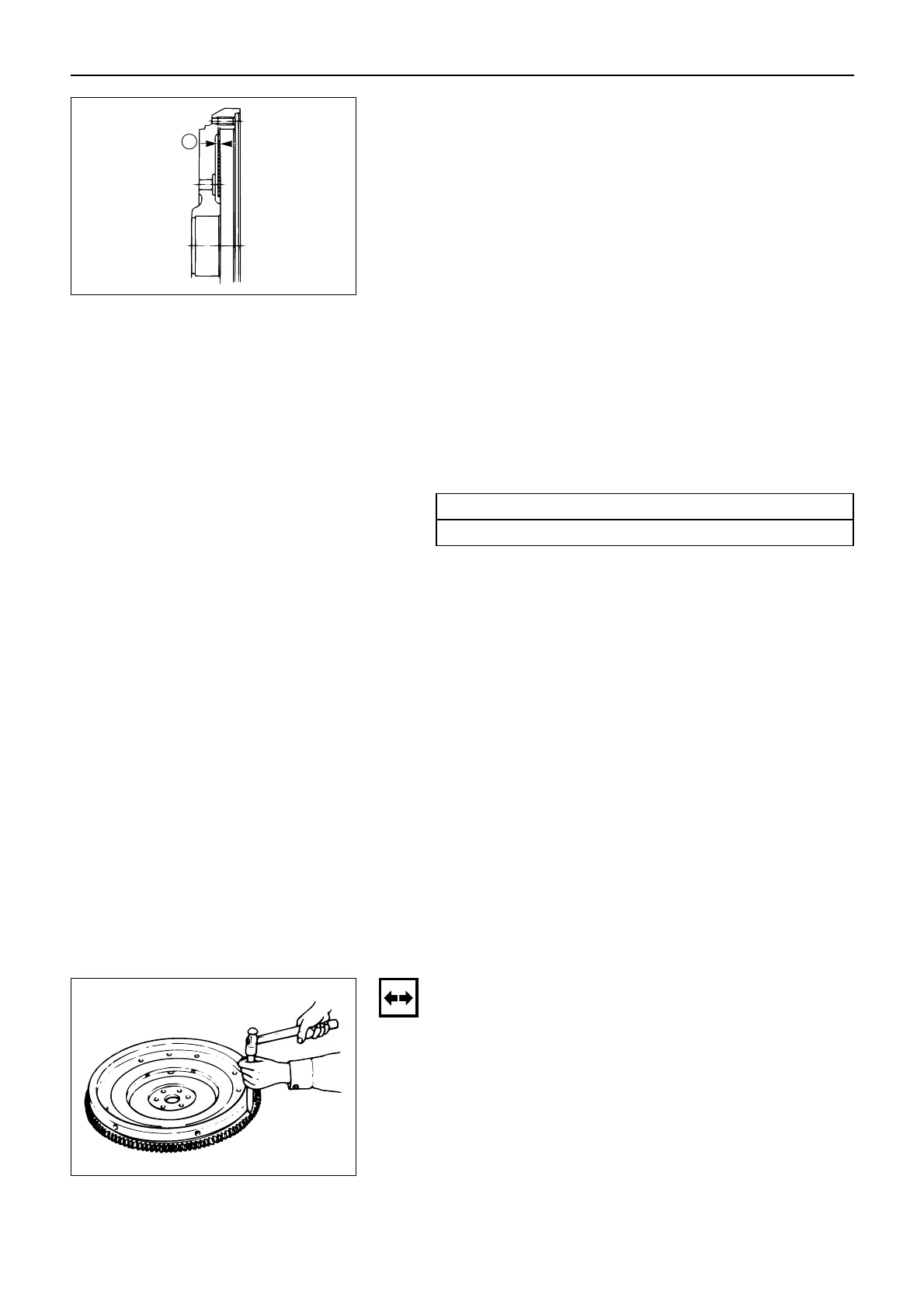

Flywheel

1. Inspect the flywheel friction surface for excessive

wear and heat cracks.

2. Measure the flywheel friction surface wear amount

(depth)

The flywheel friction surface area actually making

contact with the clutch driven plate (the shaded area

in the illustration) will be smaller than the original

machined surface area.

There will be a ridge on the flywheel surface area.

Be sure to measure the surface wear in the area

inside the ridge.

If the measured value is between the standard and

the specified limit, the flywheel may be reground.

If the measured value exceeds the specified limit,

the flywheel must be replaced.

Flywheel Friction Surface Depth 1 mm(in)

Limit

1.0 (0.04) or more

Note:

Because a ridge is produced at the flywheel friction sur-

face as illustrated, do not measure the friction surface

wear amount at the non-ridge area but be sure to

measure it at the rear-friction surface which is shown in

the illustration by shaded area.

72

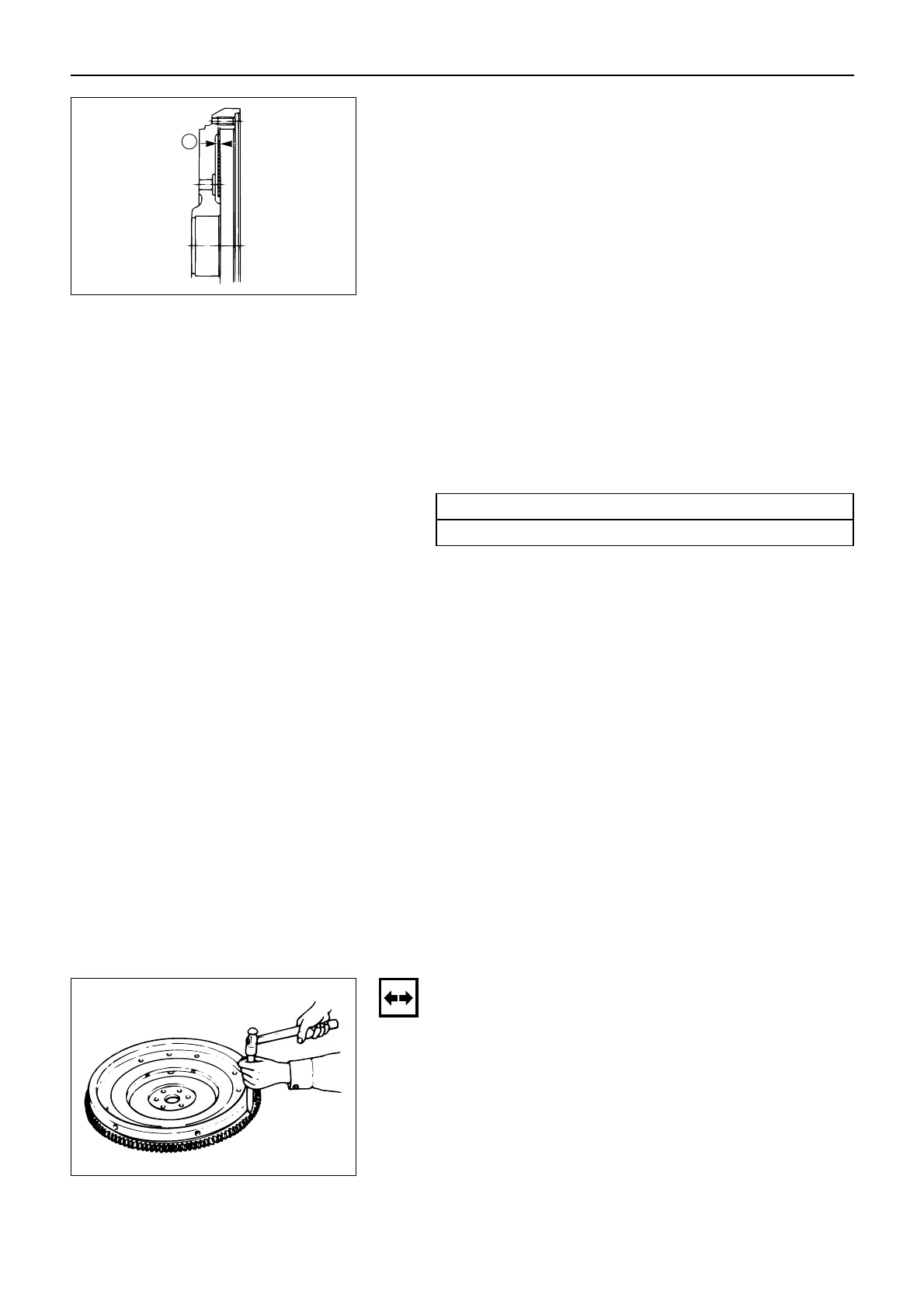

Ring Gear Replacement

Ring Gear Removal

Strike around the edges of the ring gear with a hammer

and diesel to remove it.

Ring Gear

Inspect the ring gear.

If the ring gear teeth are broken or excessively worn, the

ring gear must be replaced.

Loading...

Loading...