MAINTENANCE

Injection Nozzle

Injection Nozzle Inspection

Use a nozzle tester to check the injection nozzle opening

pressure and the spray condition.

If the opening pressure is above or below the specified

value, the injection nozzle must be replaced or recondi-

tioned.

If the spray condition is bad, the injection nozzle must be

replaced or reconditioned.

Injection Nozzle Opening Pressure kgf/cm

2

(psi/MPa)

185 (2,630/18.1)

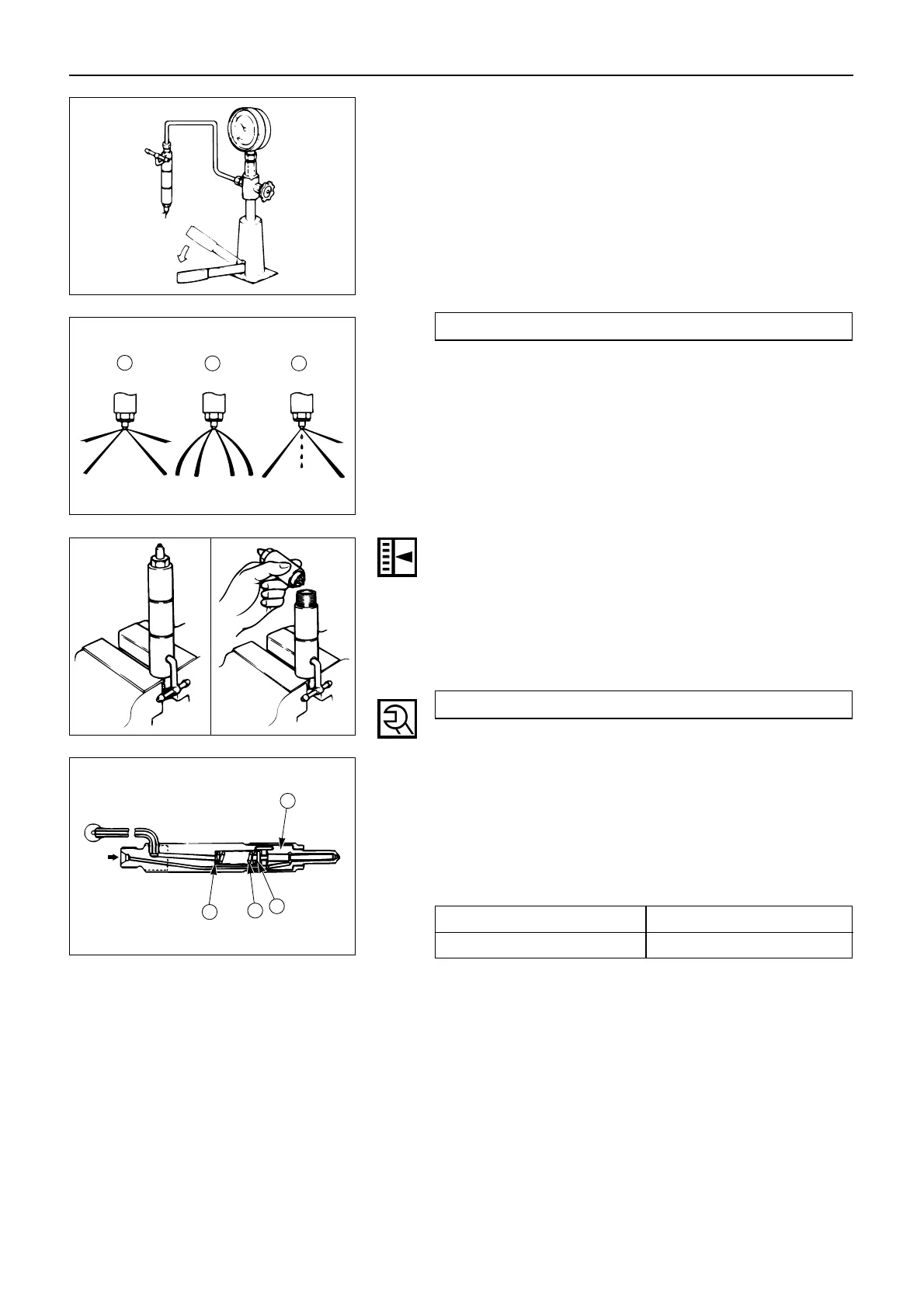

Spray Condition

(1) Correct

(2) Incorrect (Restrictions in orifice)

(3) Incorrect (Dripping)

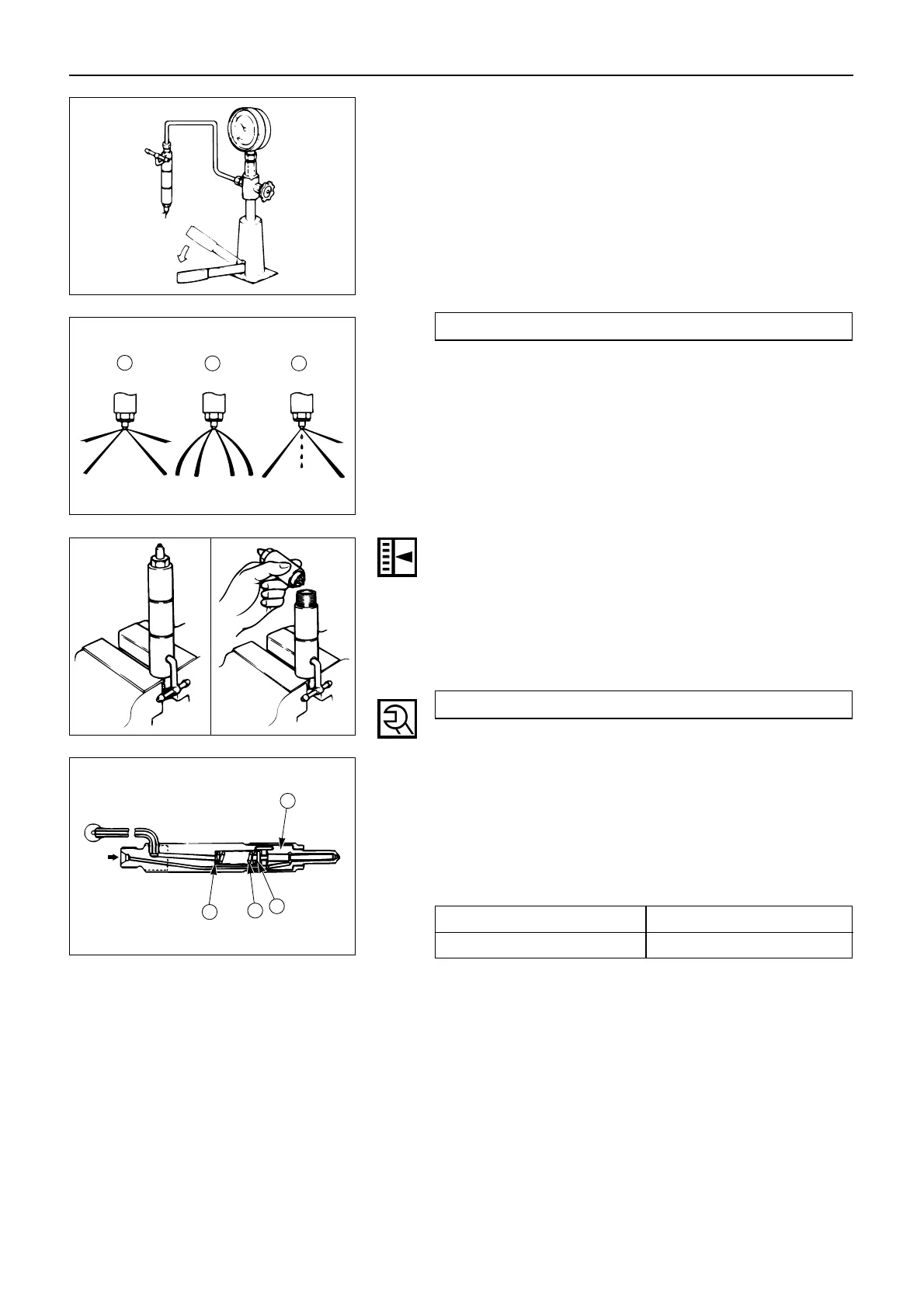

Injection Nozzle Adjustment

1. Clamp the injection nozzle in a vise.

2. Use a wrench to remove the injection nozzle retain-

ing nut.

3. Install the injection nozzle 1 , the push rod 2 , the

spring 3 , and adjusting shim 4.

Retaining Nut Torque kgf·m(lb.ft./N·m)

4.0 – 5.0 (28.9 – 36.2/39.2 – 49.0)

4. Attach the injection nozzle holder to the injection

nozzle tester.

5. Apply pressure to the nozzle tester to check that the

injection nozzle opens at the specified pressure.

If the injection nozzle does not open at the specified

pressure, install or remove the appropriate number

of adjusting shims to adjust it.

Adjusting Shim Availability mm(in.)

Range 0.50 – 1.50 (0.02 – 0.06)

Increment 0.025 (0.001)

Total No. of Shims 40

(Reference)

Removing or installing one shim will increase or

decrease the nozzle opening pressure approximately

3.77 kgf/cm

2

(53.6 psi/370kPa).

WARNING:

TEST FLUID FROM THE INJECTION NOZZLE TESTER

WILL SPRAY OUT UNDER GREAT PRESSURE. IT CAN

EASILY PUNCTURE A PERSON’S SKIN. KEEP YOUR

HANDS AWAY FROM THE INJECTION NOZZLE TESTER

AT ALL TIMES.

Loading...

Loading...