ENGINE ASSEMBLY ( 2 )

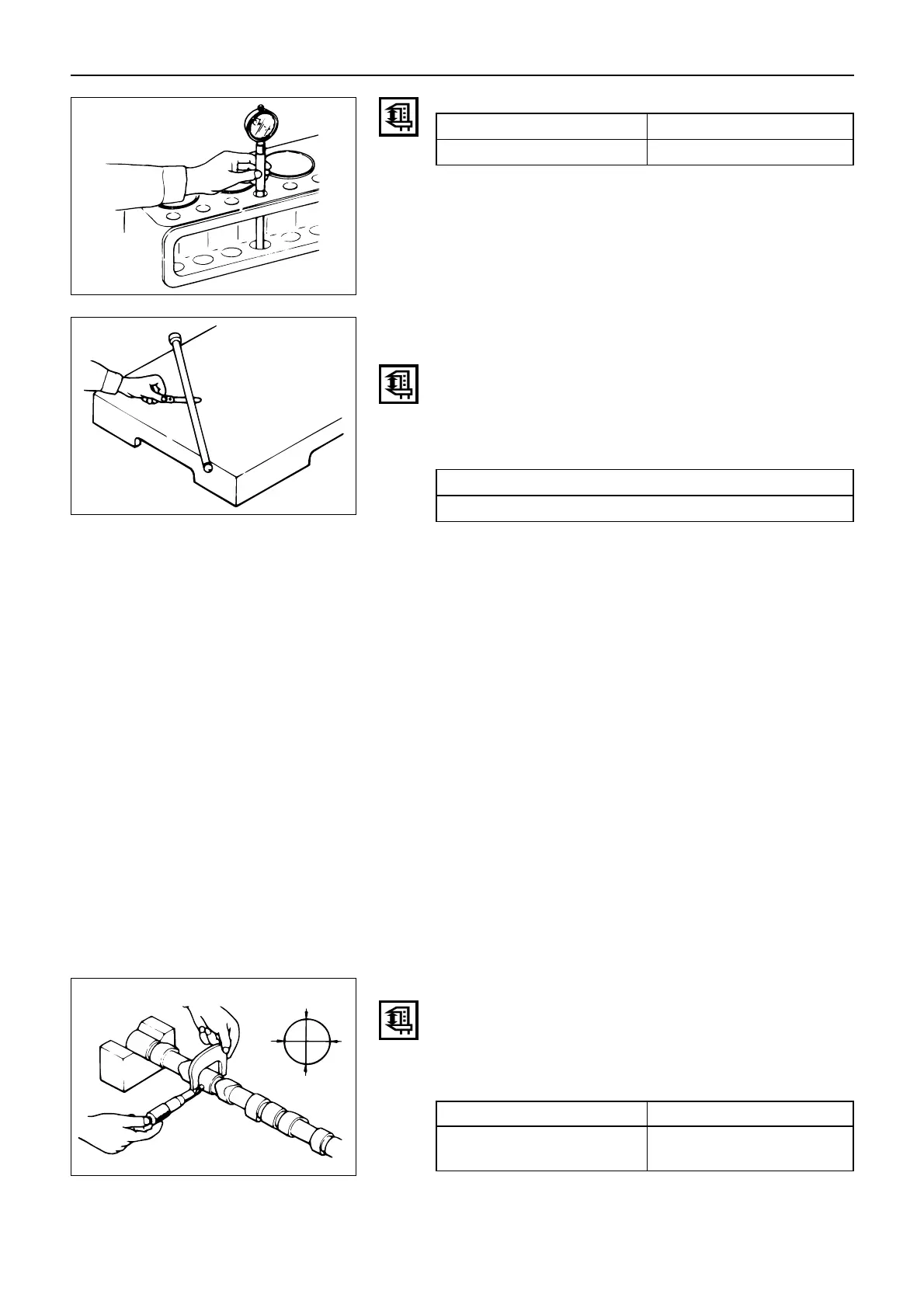

Tappet and Cylinder Body Clearance mm(in)

Standard Limit

0.03 (0.0012) 0.1 (0.0039)

62

Push Rod Curvature

1. Lay the push rod on a surface plate.

2. Roll the push rod along the surface plate and mea-

sure the push rod curvature with a thickness gauge.

If the measured value exceeds the specified limit,

the push rod must be replaced.

Push Rod Curvature mm(in)

Limit

0.3 (0.012)

3. Visually inspect both ends of the push rod for

excessive wear and damage. The push rod must be

replaced if these conditions are discovered during

inspection.

CAMSHAFT

Visually inspect the journals, the cams, the oil pump

drive gear, and the camshaft bearings for excessive

wear and damage. The camshaft and the camshaft

bearings must be replaced if these conditions are

discovered during inspection.

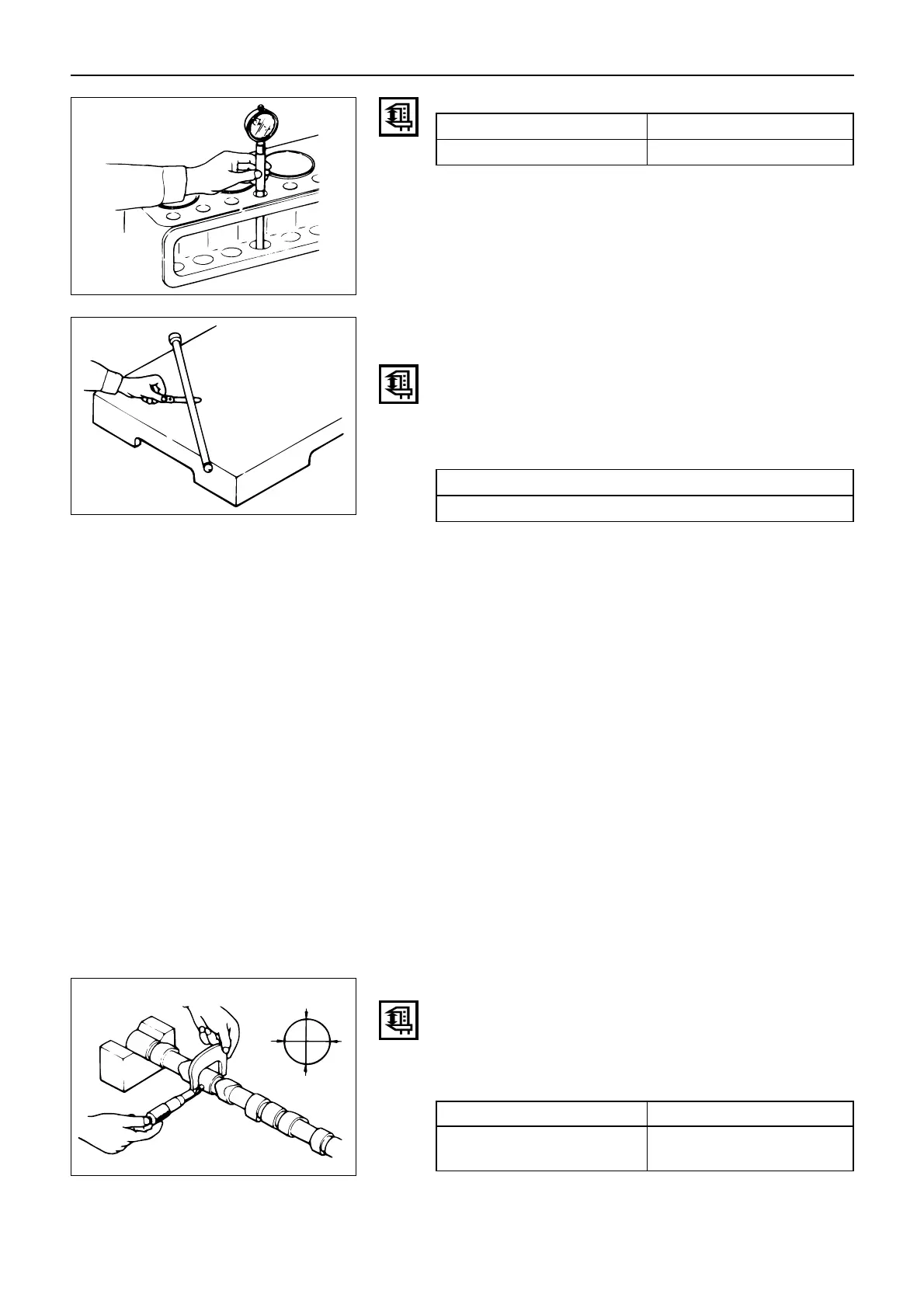

Camshaft Journal Diameter

Use a micrometer to measure each camshaft journal

diameter in two directions ((X – X) and (Y – Y)). If the

measured value is less than the specified limit, the

camshaft must be replaced.

Camshaft Journal Diameter mm(in)

Standard Limit

49.945 – 49.975 49.60

(1.9663 – 1.9675) (1.953)

Loading...

Loading...