ENGINE ASSEMBLY ( 2 )

Crankpin and Bearing Clearance

If the clearance between the measured bearing inside

diameter and the crankpin exceeds the specified limit,

the bearing and/or the crankshaft must be replaced.

Crankpin and Bearing Clearance mm(in)

Standard Limit

0.029 – 0.066 (0.0011 – 0.0026) 0.10 (0.0039)

68

Clearance Measurements (With Plastigage)

Crankshaft Journal and Bearing Clearance

1. Clean the cylinder body, the journal bearing fitting

surface, the bearing caps, and the bearings.

2. Install the bearings to the cylinder body.

3. Carefully place the crankshaft on the bearings.

4. Rotate the crankshaft approximately 30° to seat the

bearing.

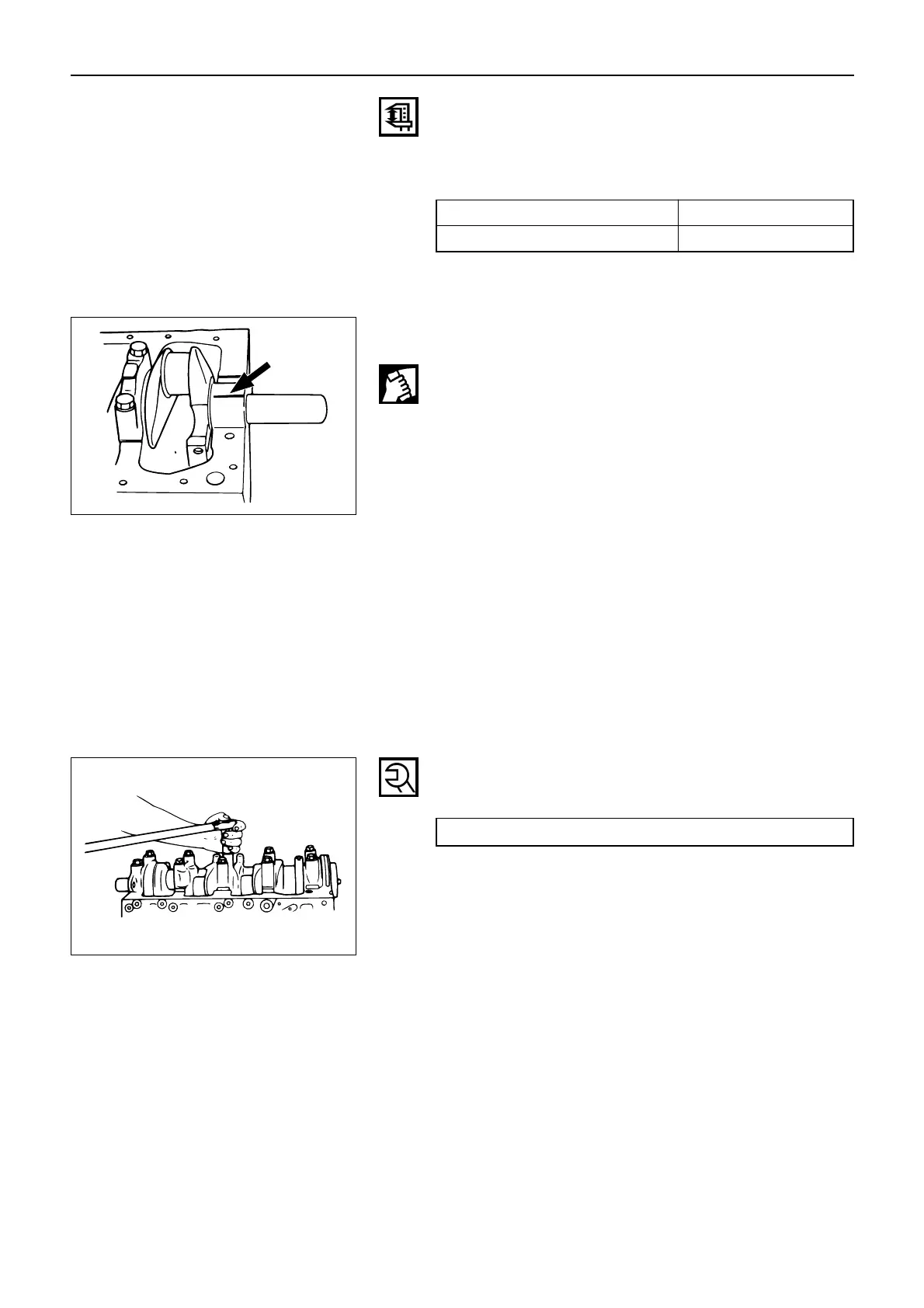

5. Place the Plastigage (arrow) over the crankshaft

journal across the full width of the bearing.

6. Install the bearing caps with the bearing.

7. Tighten the bearing caps to the specified torque.

Crankshaft Bearing Cap Bolt

Torque kgf·m(lb.ft/N·m)

16.0 – 18.0 (115.7 – 130.2/156.9 – 176.5)

Do not allow the crankshaft to turn during bearing

cap installation and tightening.

8. Remove the bearing cap.

Loading...

Loading...