MAINTENANCE

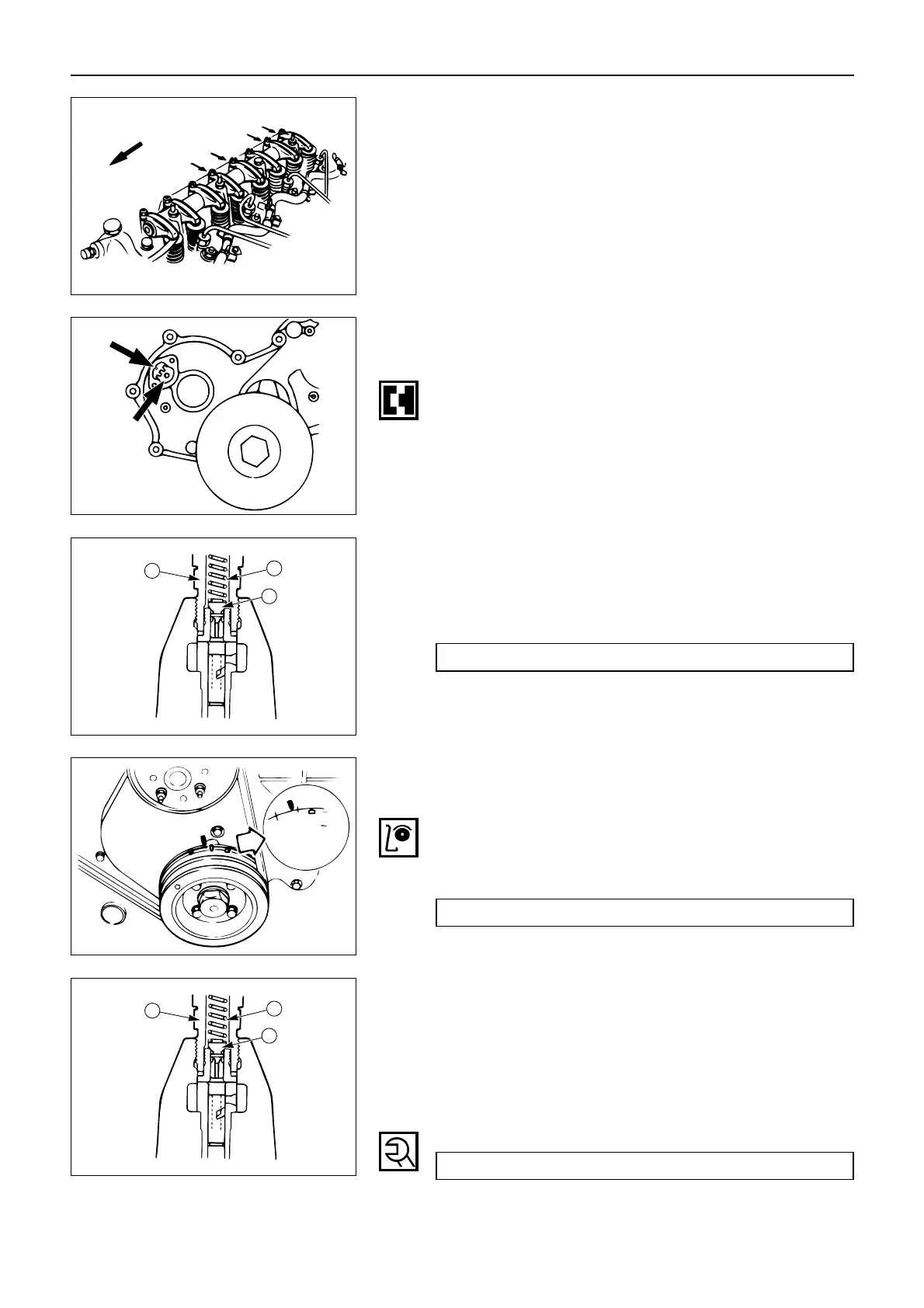

Rotate the crankshaft 360°.

Realign the crankshaft damper pulley TDC line with the

timing pointer.

Adjust the clearances for the remaining valves as shown

in the illustration. (At TDC on the compression stroke of

the No. 4 stroke)

INJECTION TIMING

Injection Timing Confirmation Procedure

1. In-line type injection pump

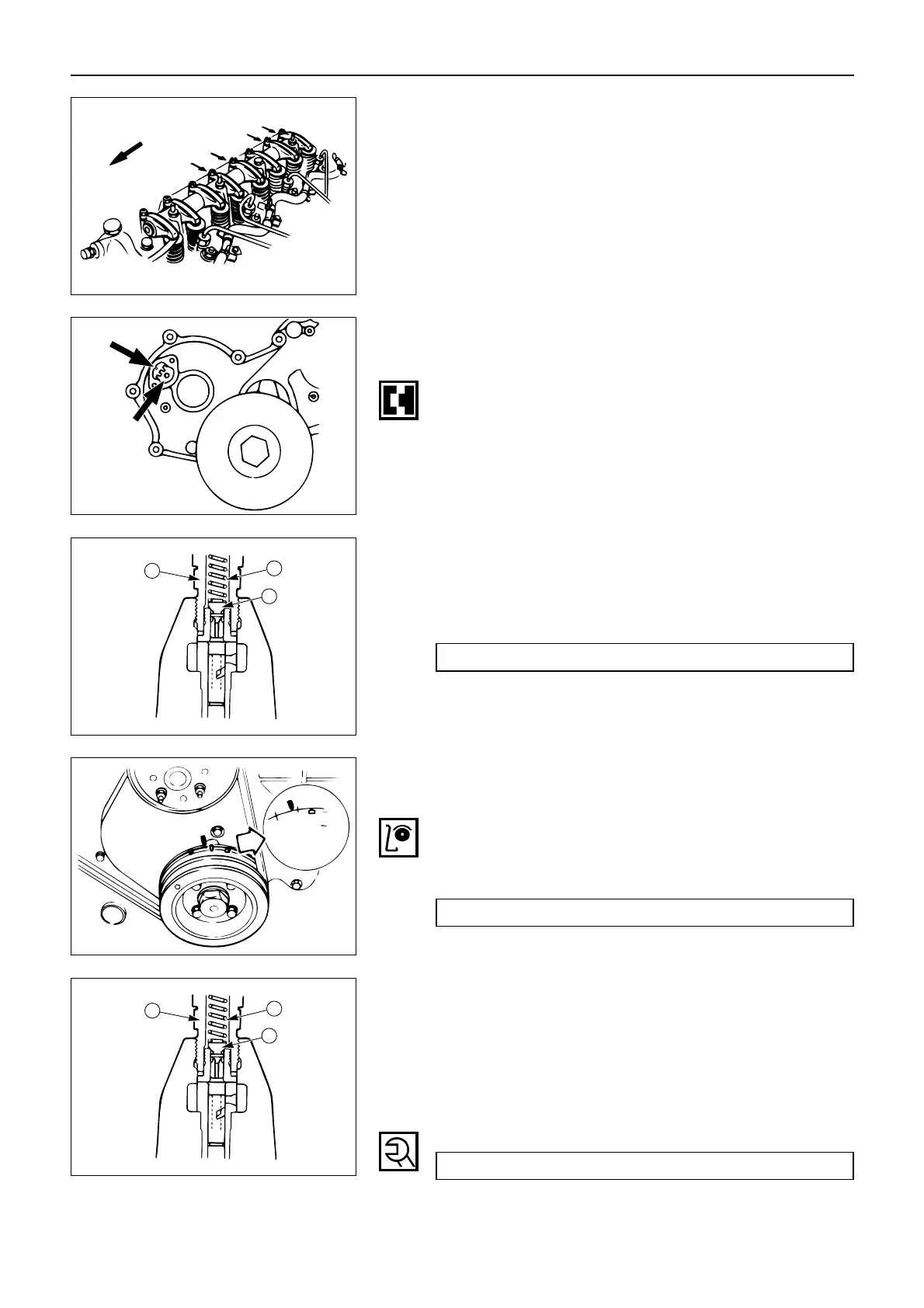

1) Rotate the crankshaft clockwise to align the cam-

shaft gear timing mark “O” with the timing gear

case cover pointer.

The No. 1 cylinder will now be at the point where

nearly injection timing.

2) Remove the No. 1 fuel injection pipe.

3) Remove the delivery valve holder 1 , the delivery

valve spring 2 , and the delivery valve 3 .

4) Tighten the delivery valve holder to the specified

torque.

Delivery Valve Holder Torque kgf·m(lb.ft/N·m)

4.0 – 4.5 (28.9 – 32.5/39.2 – 44.1)

5) Operate the injection pump priming pump while

slowly rotating the crankshaft until fuel stops flow-

ing from the delivery valve holder.

6) Conform that the crankshaft damper pulley notched

line is aligned with the timing gear case cover

pointer.

Injection Timing (Static BTDC)

14°

24

7) Remove the delivery valve holder.

8) Install the delivery valve 1 , the delivery valve

spring 2 , and the delivery valve holder 3 .

9) Tighten the delivery valve holder to the specified

torque.

10) Install the fuel injection pipes and tighten them to

the specified torque.

Fuel Injection Pipe Torque kgf·m(lb.ft/N·m)

2.0 – 4.0 (14.4 – 28.9/19.6 – 39.2)

11) Operation to air breeding.

Loading...

Loading...