G2-6 Tires and Rims 04/03 G02004

LUBRICANTS

The proper amount and type of lubricant is key to

successful mounting of radial off-road tires.

For lubrication, use only water-based or vegeta-

ble-based lubricant. Lubricants should be of a

type that vaporize over time and not leave any

residue on the rim or tire surfaces.

1. Paste lubricants should be diluted with water as

per specific lubricant manufacturers recom-

mendations.

2. Only lubricate all parts on the rim that are in con-

tact with the bead sole area of the tire.

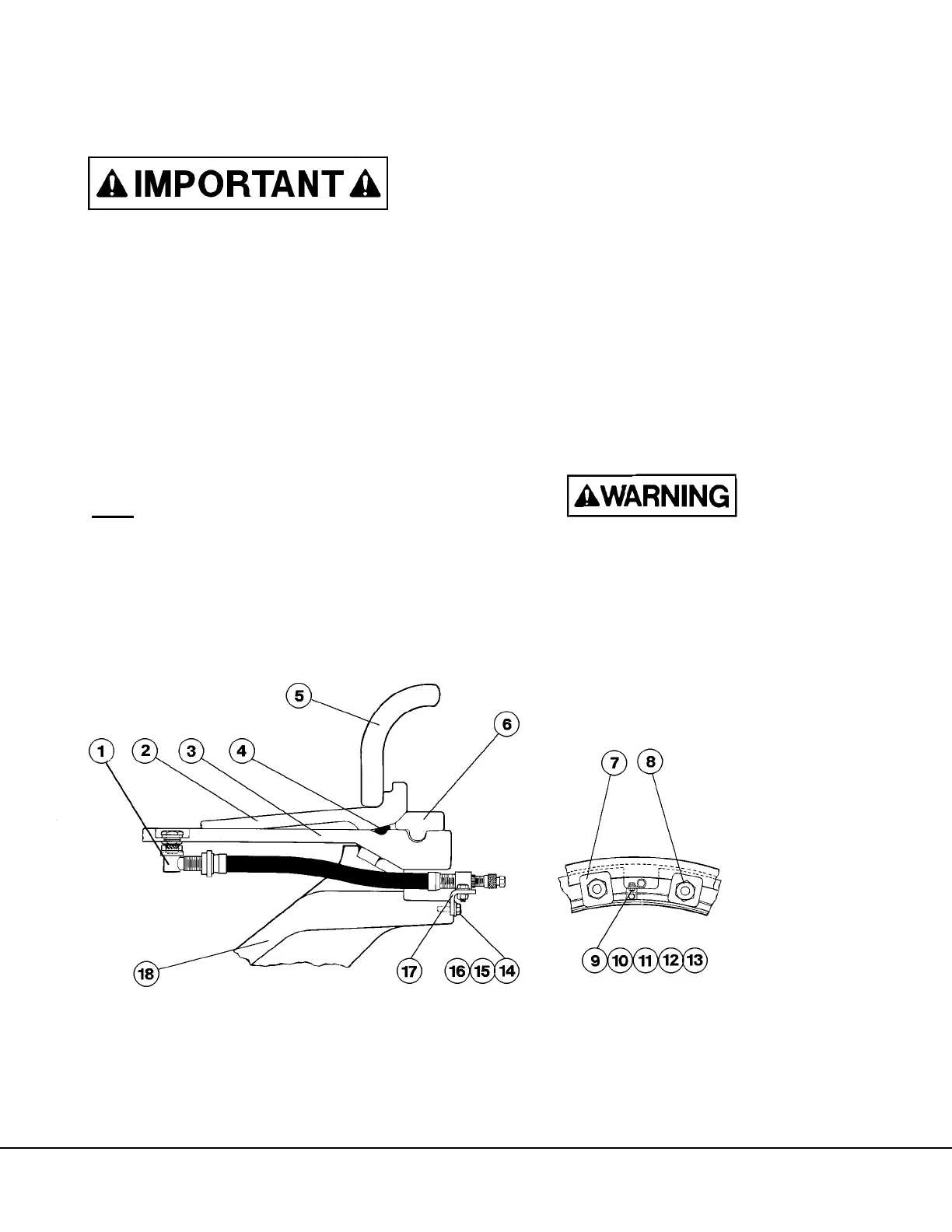

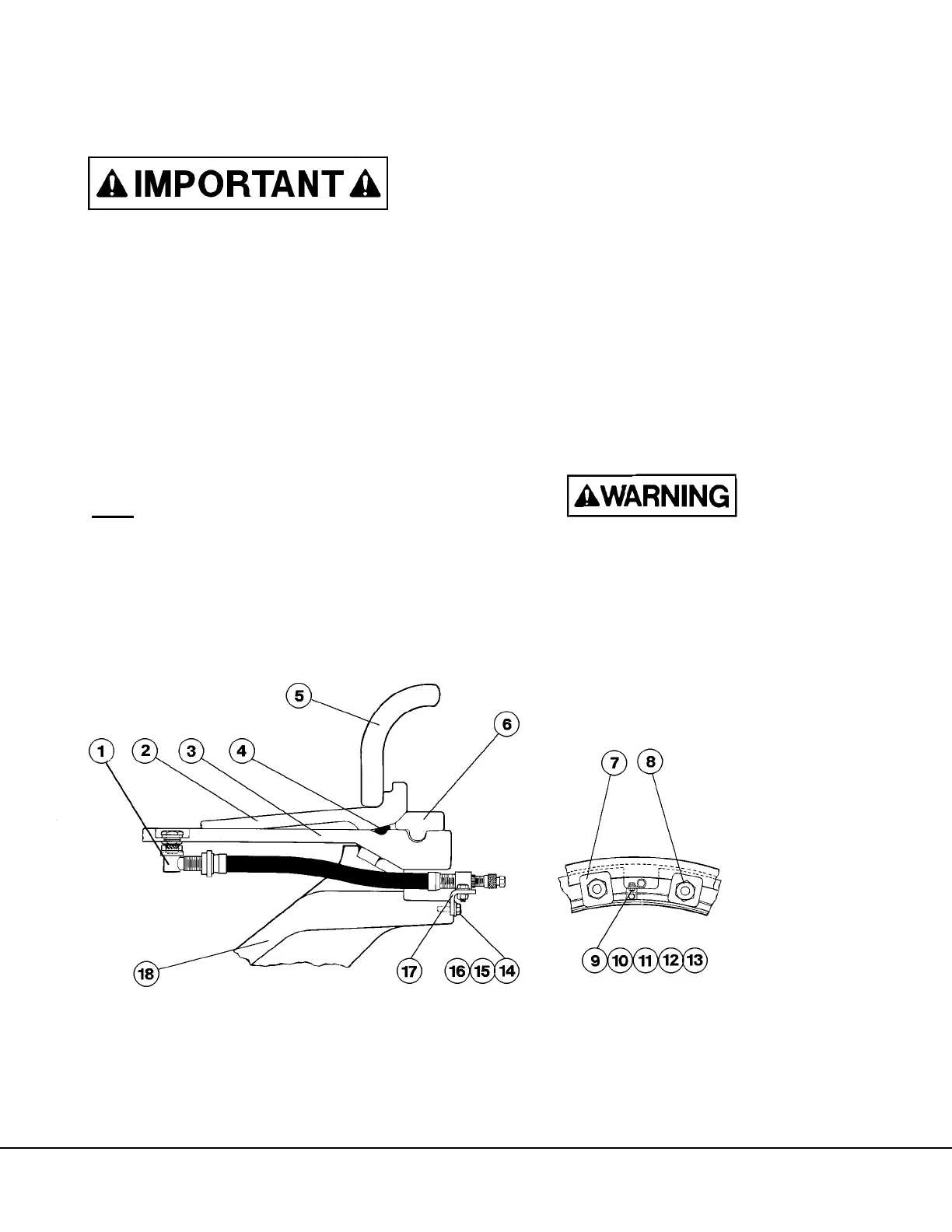

FIGURE 2-8.

NOTE: Be careful not to apply lubricant in the O-ring

gutter.

3. When lubricating the tire bead, lubricant should

be sparingly applied to the tire bead surface

ONLY

. The lubricant should be painted or

sprayed on uniformly without any lumps in the

paste or soap. The total amount of lubricant

applied per tire should not exceed 50 grams

(1.75 oz.).

TIRE INSTALLATION

The preferred method for mounting tires is horizon-

tally and off of the truck, especially for initial tire

mounting on a new truck. For horizontal tire mount-

ing, a workman’s stand is recommended for working

inside the tire. Similar methods and precautions

should be used when mounting tires vertically, on the

truck.

NOTE: With each tire mounting, it is required that a

new O-ring and a new air valve be installed.

1. Before mounting tire to rim, remove all dirt and

rust from rim parts, particularly the O-ring

groove and bead seats. It is advisable to touch

up all metal parts with a good anti-rust paint to

prevent bare metal from being exposed to the

weather.

NOTE: Do not allow paint, rust or other

contamination to cover mating faces of lockring (6)

and rim (3).

Check to be sure that proper rim parts are used

for reassembly. Use of incompatible parts may

not properly secure the assembly resulting in

violently flying parts upon inflation.

FIGURE 2-8. FRONT WHEEL ASSEMBLY

1. Valve Assembly

2. Bead Seat Band

3. Rim

4. O-Ring

5. Side Flange

6. Lock Ring

7. Wheel Retainer Lug

8. Nut

9. Capscrew

10. Flatwasher

11. Lockwasher

12. Nut

13. Clamp

14. Capscrew

15. Flatwasher

16. Lockwasher

17. Bent Plate

18. Hub

Loading...

Loading...