12. Install back-up ring, O-ring, and O-ring in flange

plate. Use clean, heavy grease to hold O-rings in

grooves.

13. Attach a piece of tape over shaft keyway to protect

seal during assembly.

14. With O-ring in flange plate facing down and keep-

ing plate true with shafts, slide it down until it

contacts dowels in gear plate. Bump flange very

lightly with hands or plastic hammer to force the

plate down on dowels, at the same time making

sure grease is holding O-rings in grooves. Once

plate is in position, remove tape protecting seal

from shaft keyway.

15. Coat capscrew (13, Figure 4-4) threads with clean

hydraulic oil. Install washers (14) on capscrews.

Tighten to 80 ft. lbs (108 N-m) torque.

16. Using a twelve inch wrench, check to see if shaft

will turn. It will be tight but should turn free with a

15 lbs (6.8 Kg) maximum force on wrench.

Installation

1. Slide motor shaft with key into flex coupling on

blower wheel shaft. Tighten set screw of flex cou-

pling to 65 ft. lbs. (88 N-m) torque.

2. Install motor mounting capscrews, tighten to

standard torque.

3. Connect all hoses, tighten split flange capscrews

to standard torque.

BLOWER BEARING REPAIR

Removal

1. Remove blower inlet and outlet hoses.

2. Loosen setscrew in flex coupling (3, Figure 4-3) on

blower wheel shaft.

3. Remove all nuts, washers and capscrews securing

housing halves. Remove inlet half of blower hous-

ing.

4. Loosen setscrews in blower wheel. Slide wheel

from shaft.

5. Remove four blower housing retainer plates from

blower housing and mount bracket.

6. Slide bearing housing and remaining blower hous-

ing half from mount brackets and flex coupling.

Replacement

1. Loosen clamp ring setscrew in locking collar (6,

Figure 4-3) of one bearing.

2. Push other bearing with shaft out of housing.

3. Remove bearing remaining in housing.

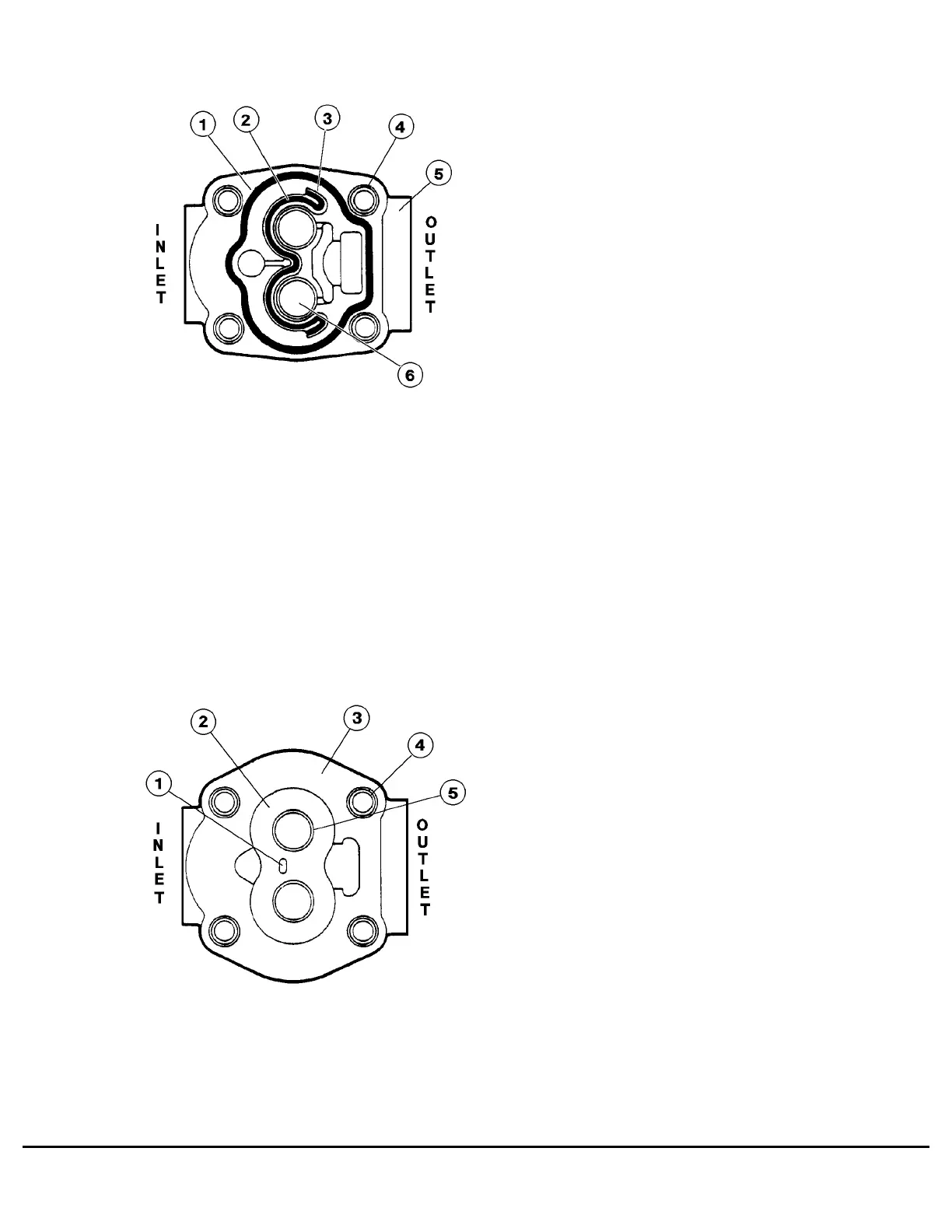

91458

FIGURE 4-6. PRESSURE PLATE INSTALLATION

1. Trap

2. Pressure Plate

3. Gear Plate

4. Dowel

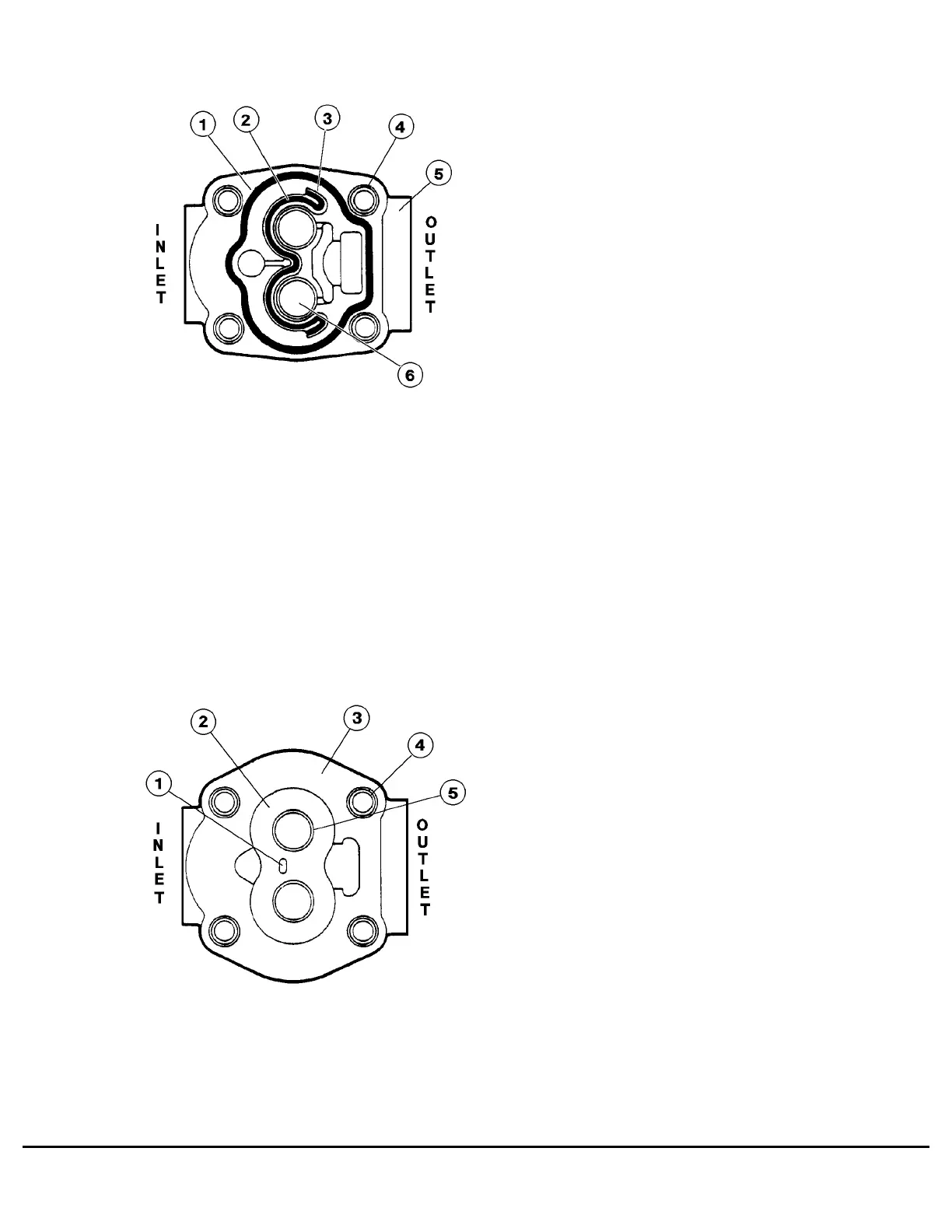

91459

FIGURE 4-5. COVER PLATE SEALS

1. O-ring

2. O-ring

3. Backup Ring

4. Dowel

5. Cover Plate

6. Drive Gear Bore

M04002 12/89 Alternator and Wheelmotor Cooling Air Filter System M4-7

Loading...

Loading...