G03018 04/03 Front Wheel Hub and Spindle G3-3

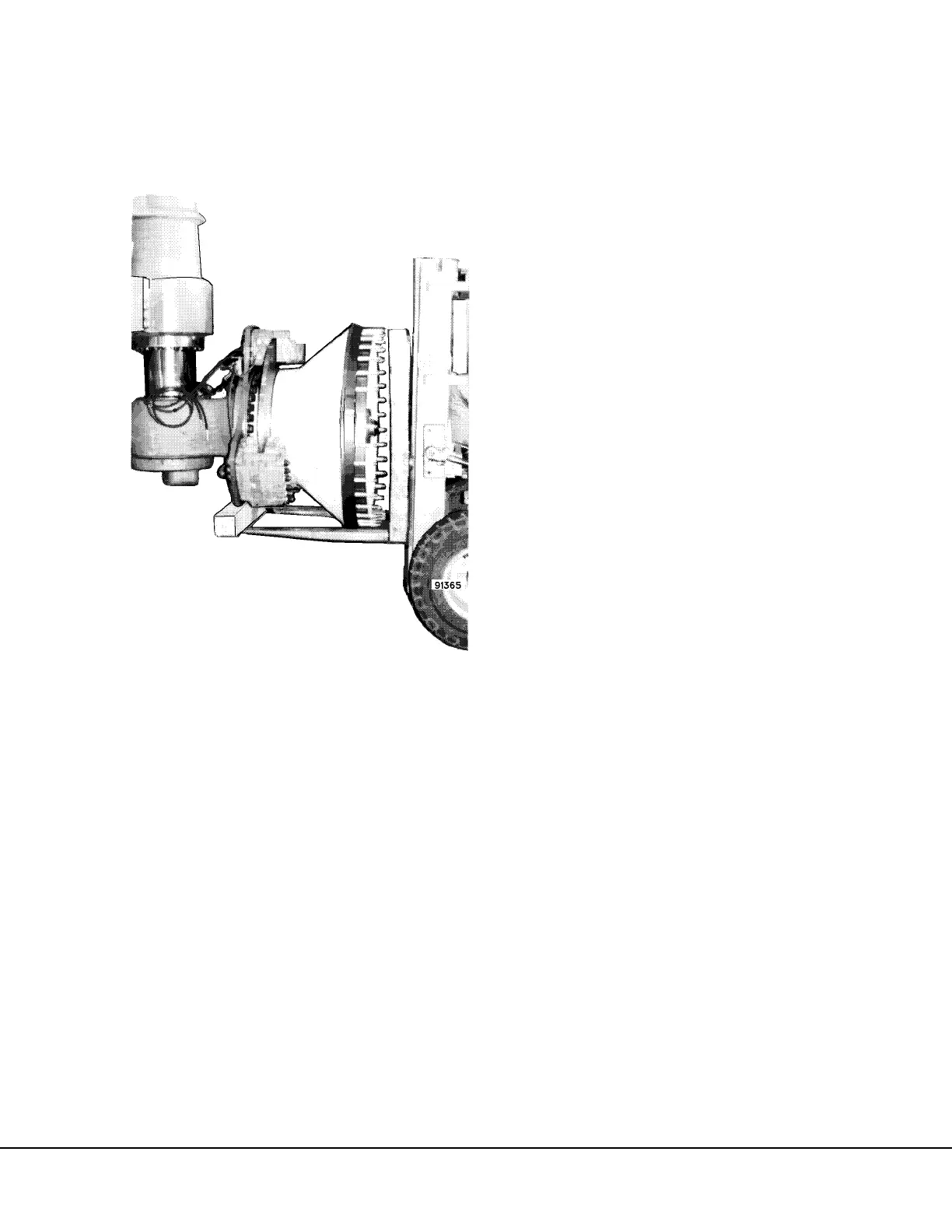

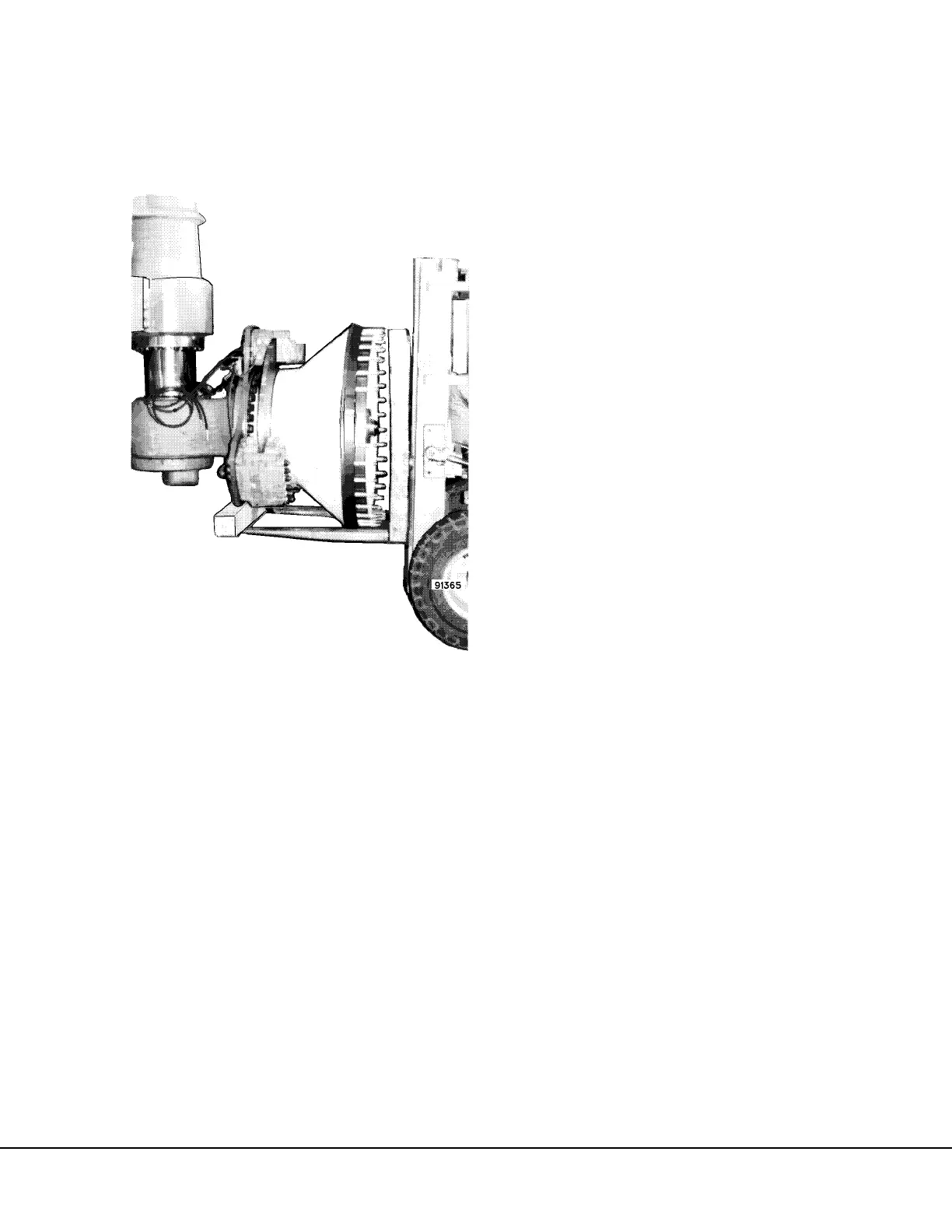

6. With a fork lift supporting the hub and spindle

assembly as shown in Figure 3-4, move to

clean work area for repair.

Installation

1. Clean spindle bore and suspension rod taper so

they are free of all rust, dirt, etc. Clean and

check the tapped holes in bottom of Hydrair®

piston for damaged threads. Retap holes, if

necessary, with 1.250 in. - 12NF tap.

2. Lubricate spindle bore and suspension rod taper

with multi-purpose grease Number 2 with 3%

Molybdenum Disulphide.

NOTE: Never use any lubricants on the spindle bore

containing copper, such as many “anti’-seize”

compounds. Products containing copper will

contribute to corrosion in this area.

3. Position spindle and wheel hub assembly on

fork lift or similar lifting device as shown in Fig-

ure 3-4.

4. Raise the spindle and wheel hub assembly into

position.

5. Secure spindle to suspension using retainer

plate (2, Figure 3-2) and capscrews (1). Tighten

capscrews using the following procedure:

a. Tighten capscrews (1) uniformly to 500 ft.

lbs. (678 N.m) torque.

b. Continue to tighten capscrews in increments

of 250 ft. lbs. (339 N.m) to obtain a final

torque of 1580 ft. lbs. (2142 N.m).

6. If removed, install steering arm (4). Clean and

check the tapped holes in bottom of spindle for

damaged threads. Retap holes, if necessary

830E, AFE 32 . . . . . . . . . .1.125 in. - 12NF tap

830E, AFE 50 . . . . . . . . . . .1.25 in. - 12NF tap

7. Install capscrews (5) and torque to:

830E, AFE 32 . . . . . . . . . . . 1430 ± 200 ft. lbs.

. . . . . . . . . . . . . . . . . . . . . . . .(1940 ± 271 N.m)

830E, AFE 50 . . . . . . . . . . . 1995 ± 100 ft. lbs.

. . . . . . . . . . . . . . . . . . . . . . . .(2705 ± 135 N.m)

8. Install steering cylinder and tie rod in their

respective mounting holes on the spindle.

Tighten retaining nuts to 525 ± 52 ft. lbs. (712 ±

71 N.m) torque. Connect lubrication lines.

9. Rotate the wheel hub to position the fill plug at

the 12 o'clock position. Remove the fill plug and

level plug. Fill wheel hub assembly at fill hole

with SAE 80W-90 oil. When properly filled, oil

should be present at the level (lower) hole.

Replace fill and level plugs.

10. Install junction block with the spacer, capscrews,

and flat washers.

11. Attach supply lines to brake calipers and connect

main supply lines to connection on frame. Bleed

brakes according to "Bleeding Brakes", Section

"J".

12. Install wheel and tires as described in "Front

Wheel and Tire Installation".

FIGURE 3-4. SPINDLE ANE WHEEL HUB

REMOVAL

Loading...

Loading...