H2-4 Front Suspensions H02016

“TURN-OF-THE-NUT” Tightening

Procedure

a. Tighten all fourteen capscrews (1, 6, 8, Figure

2-3) to 400 ±40 ft .lbs. (542 ±5 N.m) torque.

Use a torque wrench of known calibration.

b. Maintain this torque on the top two corner cap-

screws and the bottom outer four capscrews

(item 8, the 4 bottom capscrews with nuts).

c. Loosen the 8 remaining capscrews and then

tighten again using “turn-of-the-nut” tightening

procedure as follows:

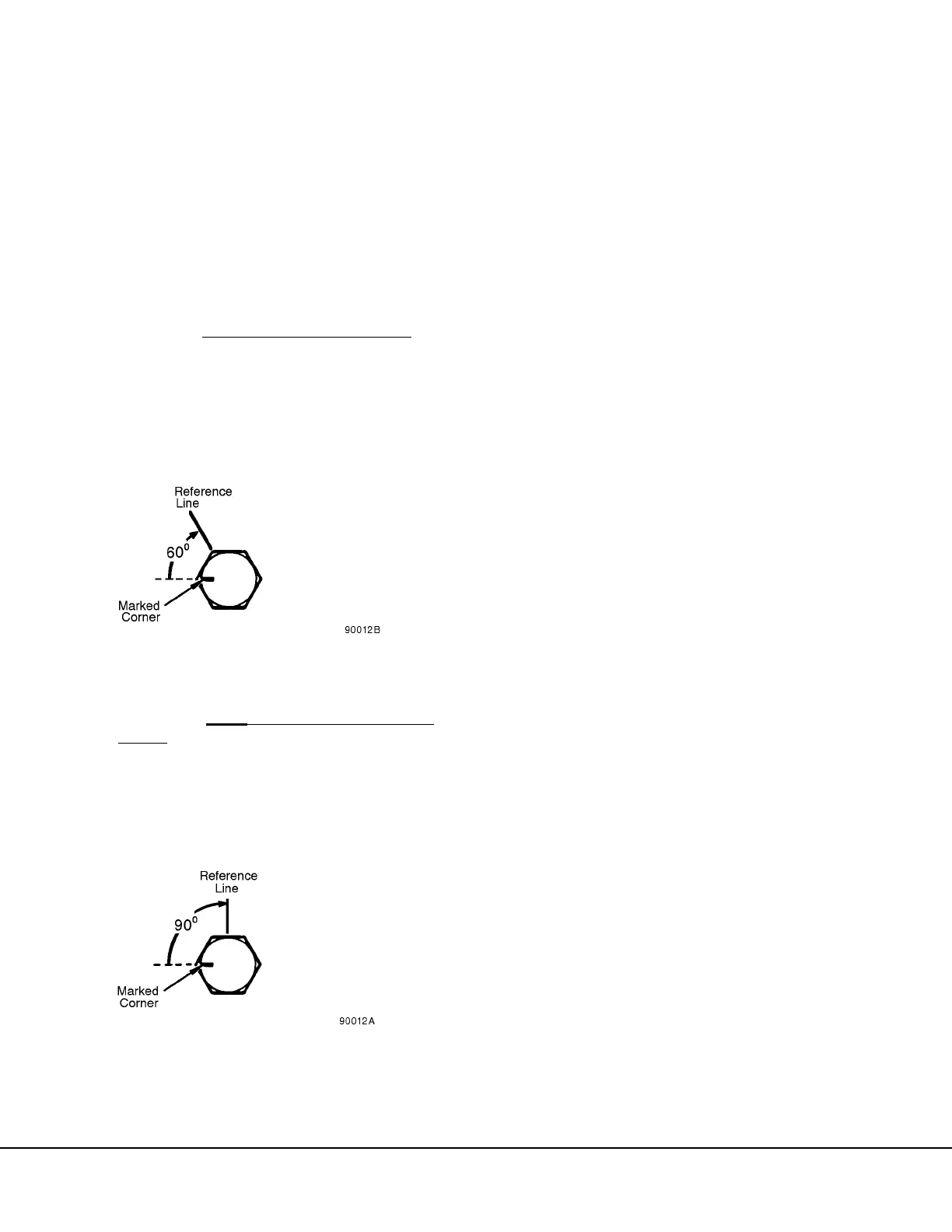

d. For the four, 6.0 in. (15 cm) long capscrews

(1,

Figure 2-3) at the upper mount, tighten cap-

screws initially to 70 ft. lbs. (95 N.m) torque;

then advance capscrew head 60° using steps

d-1.) through d-3.). Refer to Figure 2-5.

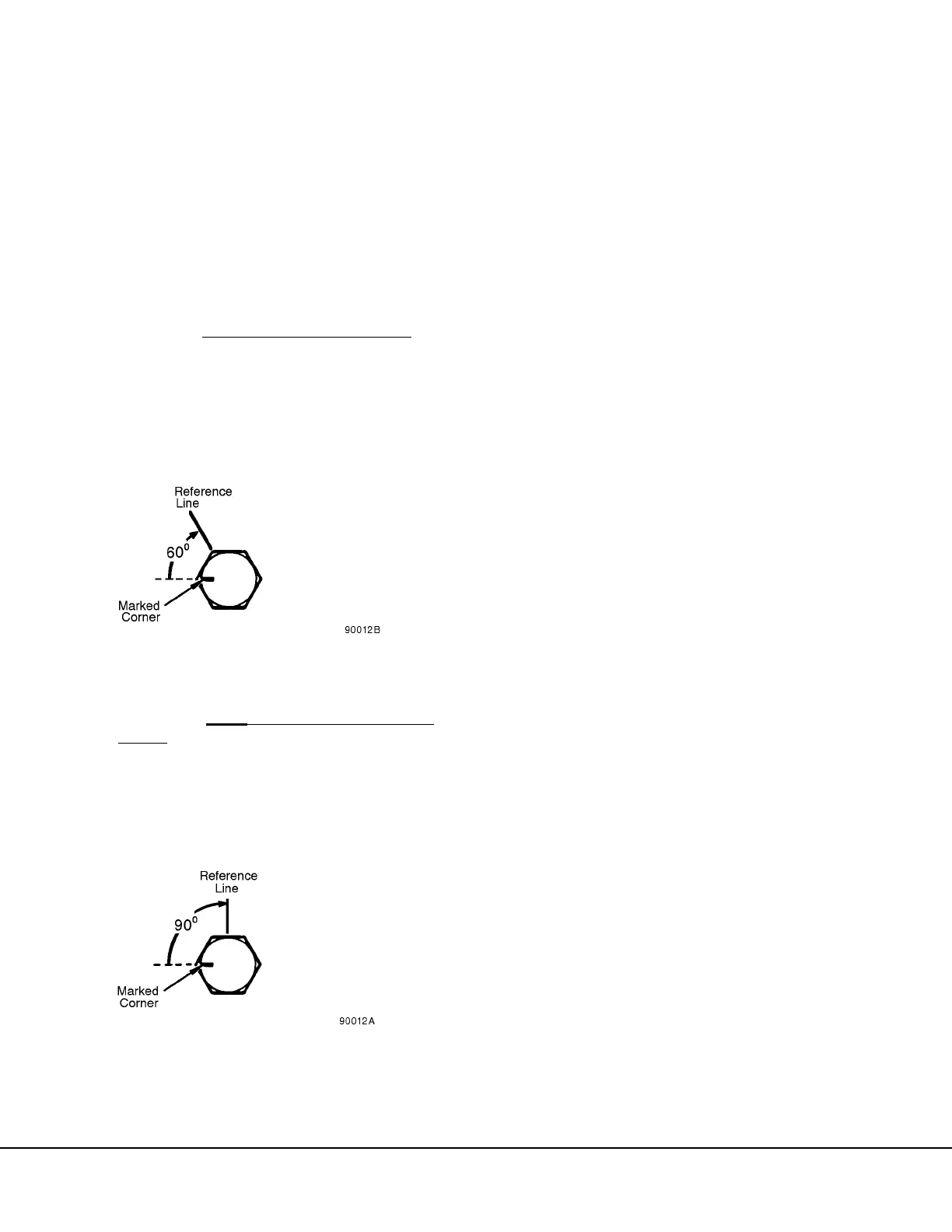

For the four inner, 12.5 in. (32 cm) long cap-

screws (6, Figure 2-3), tighten capscrews ini-

tially to 150 ft. lbs. (203 N.m) torque; then

advance capscrew head 90° using steps d-1).

through d-3). Refer to Figure 2-6.

1.) Mark a reference line on a corner of the hex-

agonal capscrew head or nut and the mount-

ing surface opposite this corner as shown.

Then mark the position located 60° or 90°

clockwise relative to the first reference line

on the mounting surface. Refer to Figures 2-

5 and 2-6.

2.) To insure that the opposite end of the turning

member, either the capscrew head or nut

remains stationary, scribe a reference mark

for this check.

3.) Each corner of a hexagon represents 60°.

The turning members, either the capscrew

head or nut, is turned until the marked cor-

ner is adjacent with the marked reference

line. Check to make sure that the opposite

end of the turning member has NOT turned

during the tightening procedure. NOTE: Do

not exceed 4 RPM tightening speed. Do

not hammer or jerk wrench during the

tightening procedure.

e. Loosen the top two corner capscrews (1) and

the bottom outer four capscrews (8, the 4

bottom capscrews with nuts).

1.) Tighten the top, two corner 6.0 in. (15 cm)

capscrews to 70 ft. lbs. (95 N.m) torque,

then use “turn-of-the-nut” method to

advance capscrew heads 60°.

2.) Tighten the bottom, outer four 12.5 in. (32

cm) capscrews to 150 ft. lbs. (203 N.m)

torque, then use “turn-of-the-nut” method to

advance capscrew heads 90°.

NOTE: If for any reason, these fasteners need to be

checked for tightness after completing the above pro-

cedure; loosen and inspect all 14 capscrews and

repeat entire process, starting with cleaning and lubri-

cating capscrews, washers, and nuts. In addition, the

capscrew head will need to be appropriately marked to

show an additional use.

7. Charge suspension with dry nitrogen to fully

extend suspension piston before installing front

wheel hub and spindle.

8. Install wheel, spindle, and tire according to

instructions in Section “G”.

9. Service the suspension. For instructions refer to

HYDRAIR

®

II “Oiling and Charging Procedure”.

10. Install suspension boot and secure with clamp.

FIGURE 2-5. REFERENCE MARKS FOR 60°

ADVANCE (6.0 in. Capscrews)

FIGURE 2-6. REFERENCE MARKS FOR 90°

ADVANCE (12.5 in. Capscrews)

Loading...

Loading...