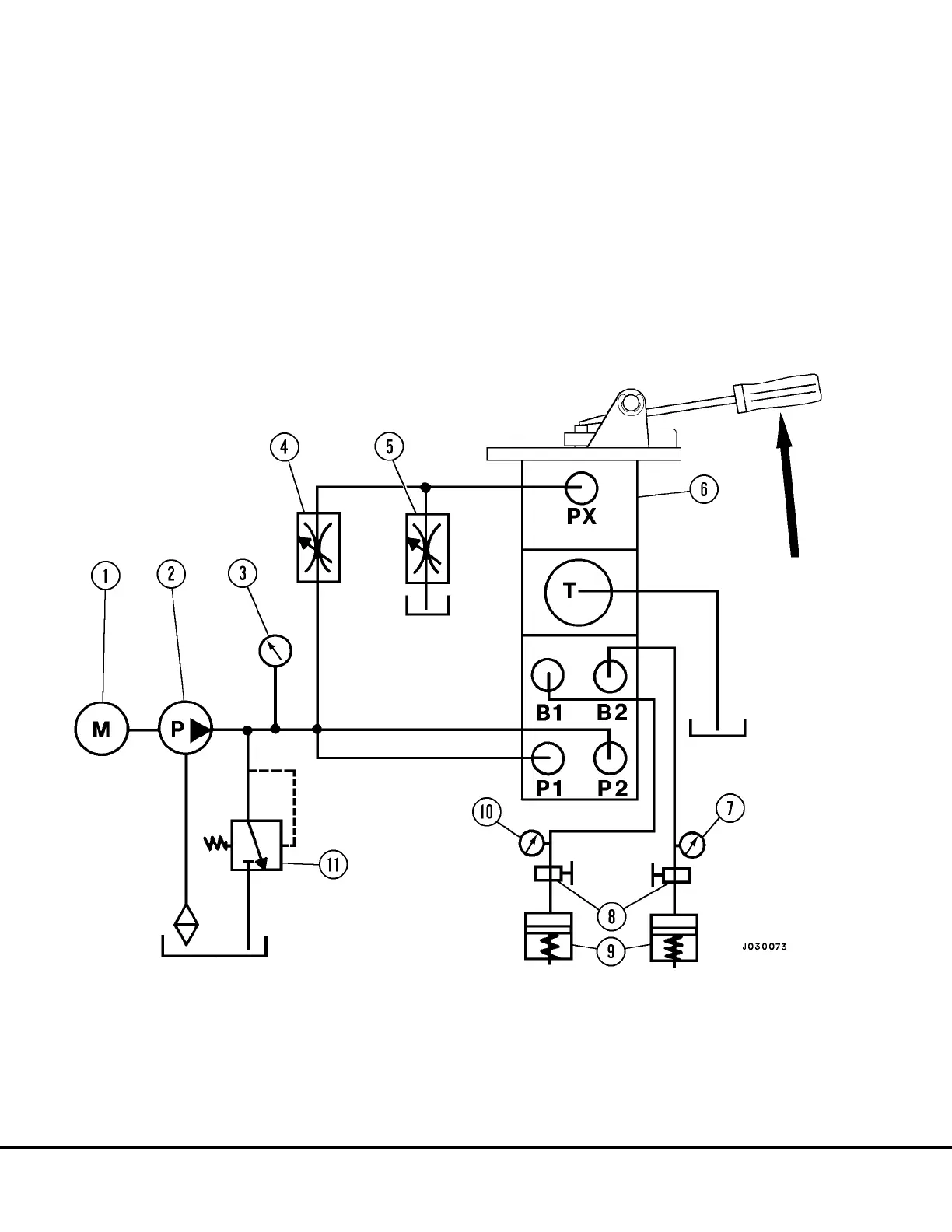

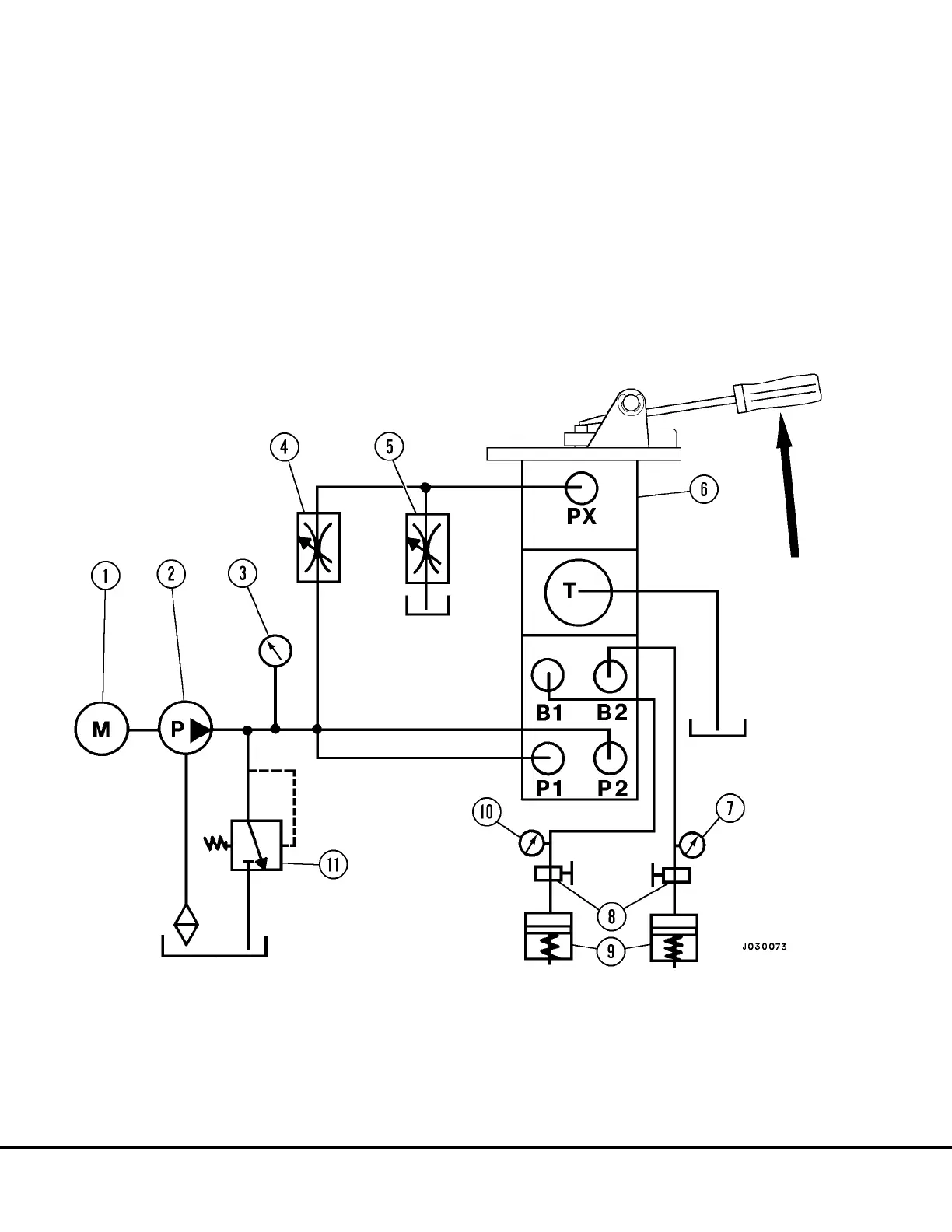

VALVE BENCH TEST AND ADJUSTMENT

The following parts and test equipment will be required

to completely bench test and adjust the dual control

treadle valve. Differrential pressure switch operation

can also be tested.

• Pressure gauges (3), 0-to-3500 psi (24 132 kPa).

• Hydraulic pressure supply, regulated to 3200 psi

(22 064 kPa).

• Hydraulic test stand, Refer to Figure 3-10.

• Hose fittings for valve ports:

Port PX is 7/16 in. – 4 SAE.

Ports P1, P2, B1 and B2 are 3/4 in. – 8 SAE.

Port T is 1 1/16 in. - 12 SAE.

• Ohmmeter

NOTE: It is possible to check the pressures with the

brake valve installed and connected to the vehicle.

Remove the brake pedal assembly and actuator cap

and boot assembly to adjust individual brake circuit

pressures.

FIGURE 3-10. TEST BENCH SET UP

1. Motor

2. Pump

3. System Pressure Gauge

4. Needle Valve

9. Simulated Brake Volume

10. Rear Brake Pressure Gauge

11. Relief Valve

5. Needle Valve

6. Brake Valve

7. Front Brake Pressure Gauge

8. Shut Off Valves

NOTE: Shut off valves (8) for tests not requiring simulated brake loads, such as circuit tracking.

NOTE: B1 Cylinder must be capable of a 10 cubic inch maximum displacement.

NOTE: B2 Cylinder must be capable of a 20 cubic inch maximum displacement.

J3-10 Brake Circuit Component Service J03022 1/99

Loading...

Loading...