2M4/2M5/2M6/2M7-1

2-1-1

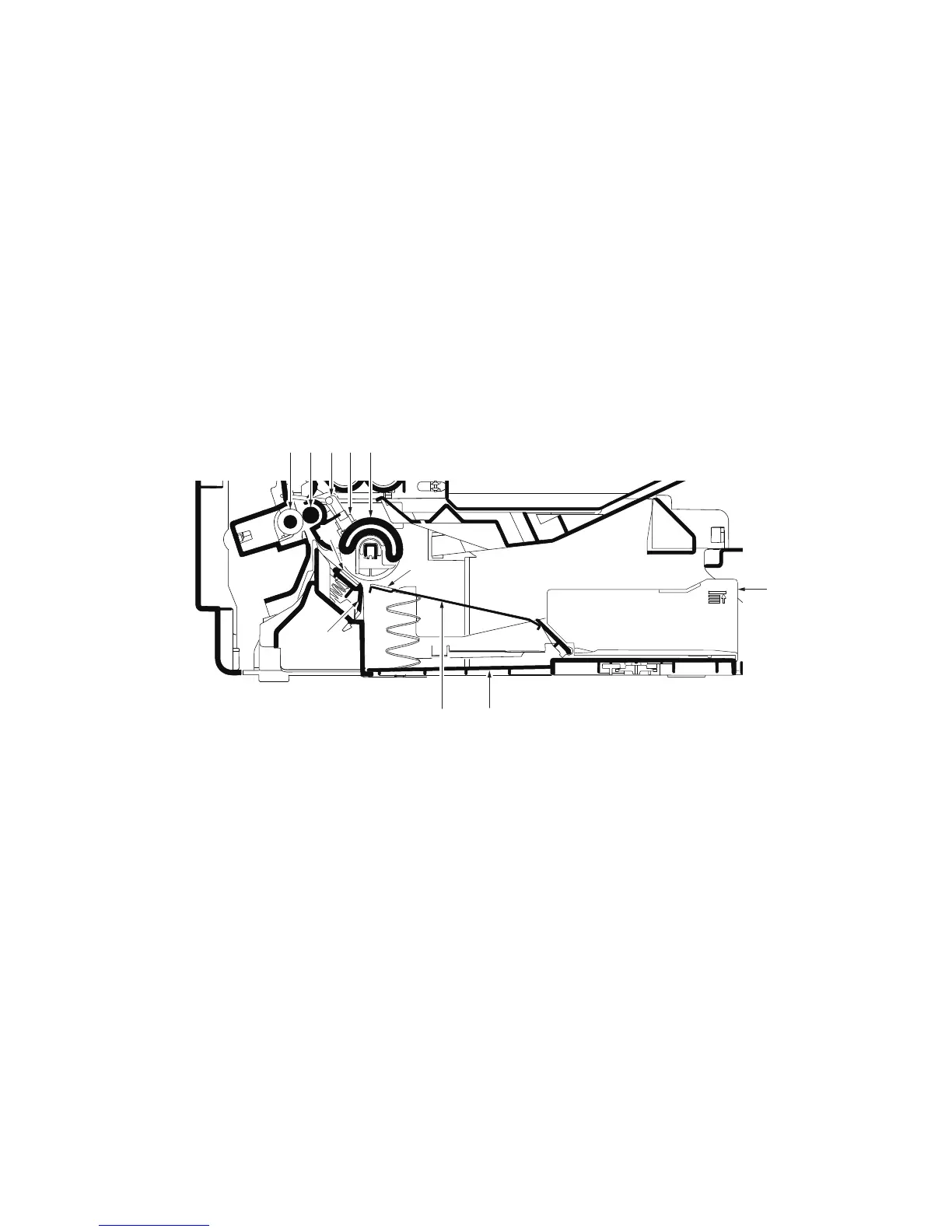

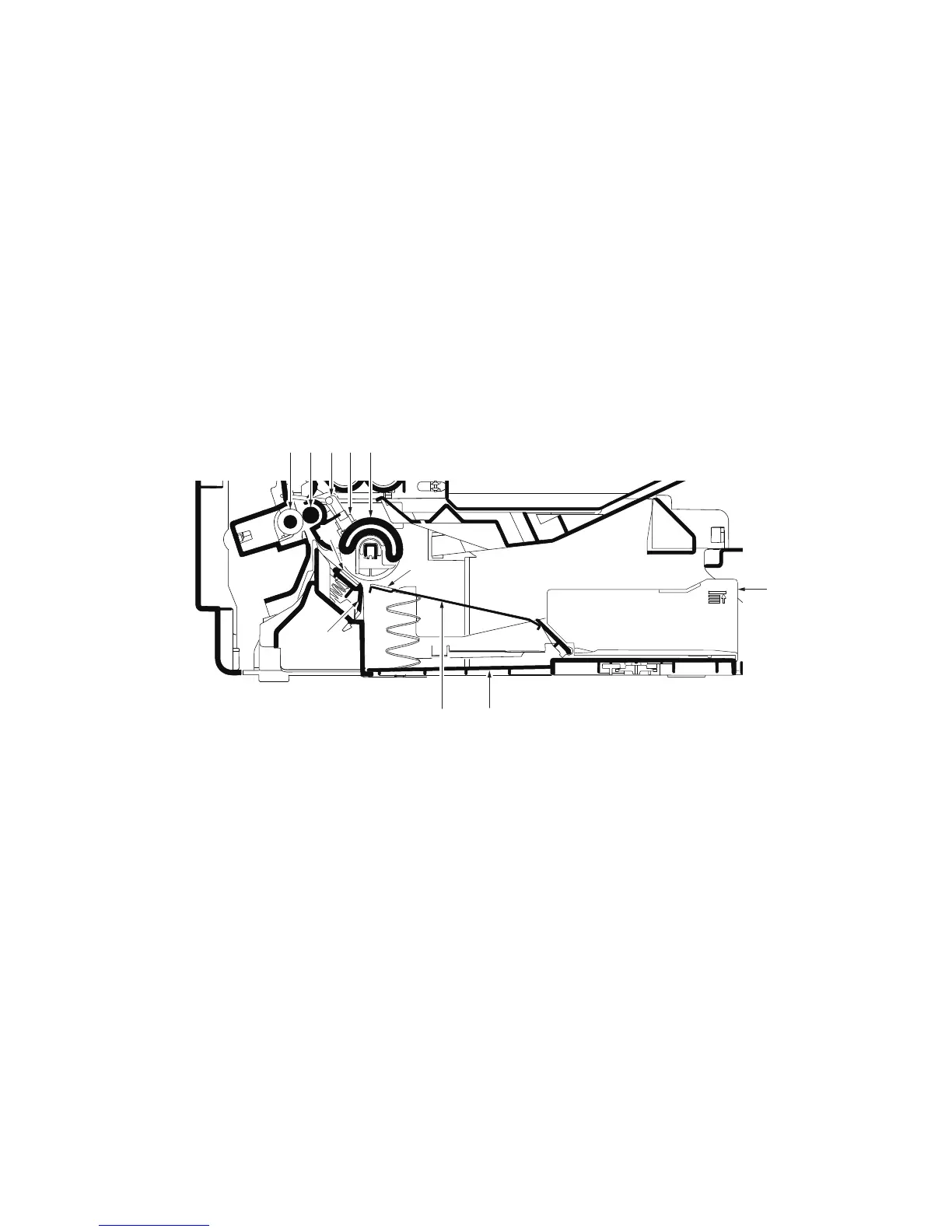

2-1 Mechanical Construction

2-1-1 Paper feed/ conveying section

Paper feed/conveying section consists of the paper feed unit that feeds paper from the cassette and the MF

tray (Manual feed tray) paper feed unit that feeds paper from the MF tray(25/26 ppm model), and the paper

conveying section that conveys the fed paper to the transfer/separation section.

(1) Cassette paper feed/ paper conveying section

Cassette paper feed section consists of the paper holder with the cassette operation plate, and the paper feed

pulley and the separation pad, for extracting and conveying the paper. Paper is fed out of the cassette by the

rotation of the paper feed pulley.

The paper conveying section conveys paper to the transfer/separation section as paper feeding from the cas-

sette or MF tray, or as paper refeeding for duplex printing (25/26 ppm model). Paper by feeding is conveyed

by the upper registration roller and lower registration roller to the transfer/separation section.The timing to

start image formatting by laser is triggered by the regist sensor (RS) and in synchronization with the paper.

Figure 2-1-1 Cassette paper feed section

1

2

4

3

5 6

7

98 10 11

1. Paper feed pulley

2. Separation pad

3. Separation pad holder

4. Bottom pad

5. Cassette operation plate

6. Cassette base

7. Guide R/F

8. Lower registration roller

9. Upper registration roller

10. Actuator (regist deflection sensor)

11. Registration sensor (RS)

Loading...

Loading...