9300 Servo PLC

System blocks

2.12 MCTRL_MotorControl

2-50

L

ServoPLC EN 2.0

2.12.14 Feedback system

Use the following codes to configure the feedback system for the position controller and speed

controller:

Code LCD

Possible settings

IMPORTANT

Lenze Selection

[C0420] Encoder const 512 Encoder: Constant for encoder input

X8

1 {1 inc/rev} 8192

[C0490] Feedback pos 0 Feedback system for the speed con-

troller

• C0490 = 0, 1, 2 can be mixed

with

C0495 = 0, 1, 2.

• C0490 = 3, 4 sets C0495 to the

same value.

0 Resolver at X7

1 Encoder TTL at X8

2 sin/cos encoder at X8

3 Absolute value encoder ST at X8

4 Absolute value encoder MT at X8

[C0495] Feedback n Feedback system for the speed con-

troller

• C0495 = 0, 1, 2 can be mixed

with

C0490 = 0, 1, 2.

• C0495 = 3, 4 sets C0490 to the

same value.

0 Resolver at X7

1 Encoder TTL at X8

2 sin/cos encoder at X8

3 Absolute value encoder ST (single turn) at X8

4 Absolute value encoder MT (multi turn) at X8

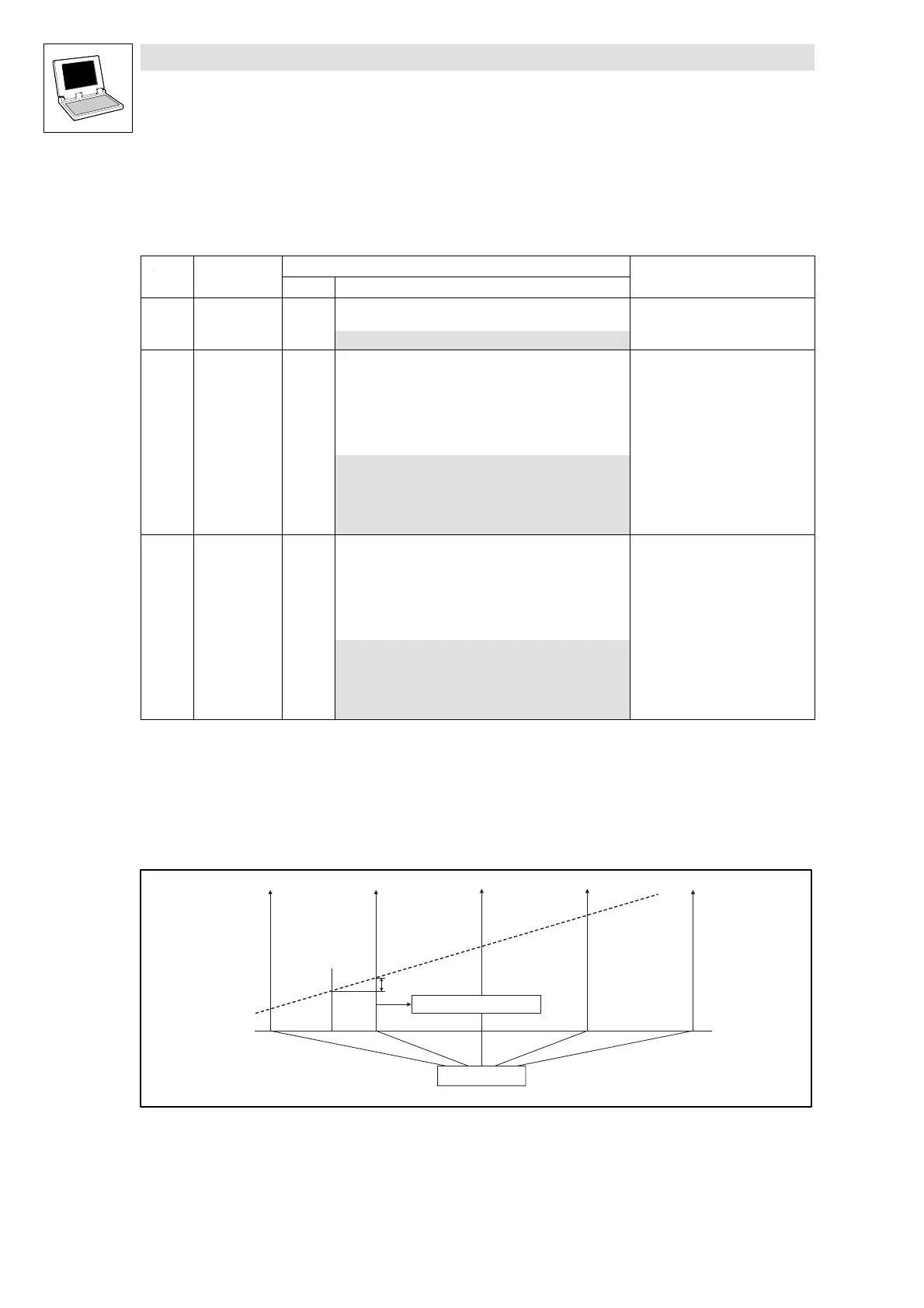

2.12.15 Touch probe (TP)

Process: The current angle value (digital frequency input value) is stored by a quick interrupt in the

operating system when a signal change occurs at the TP activating input (e.g. X5/E4).

MCTRL_dnActIncLastScan_p

TP

j

Fig. 2-25 Function diagram of a TP

Time-equidistant start of an interval-task

ϕ Phase-angle signal

efesotomasyon.com - Lenze

Loading...

Loading...