9300 Servo PLC

Appendix

3-5

l

ServoPLC EN 2.0

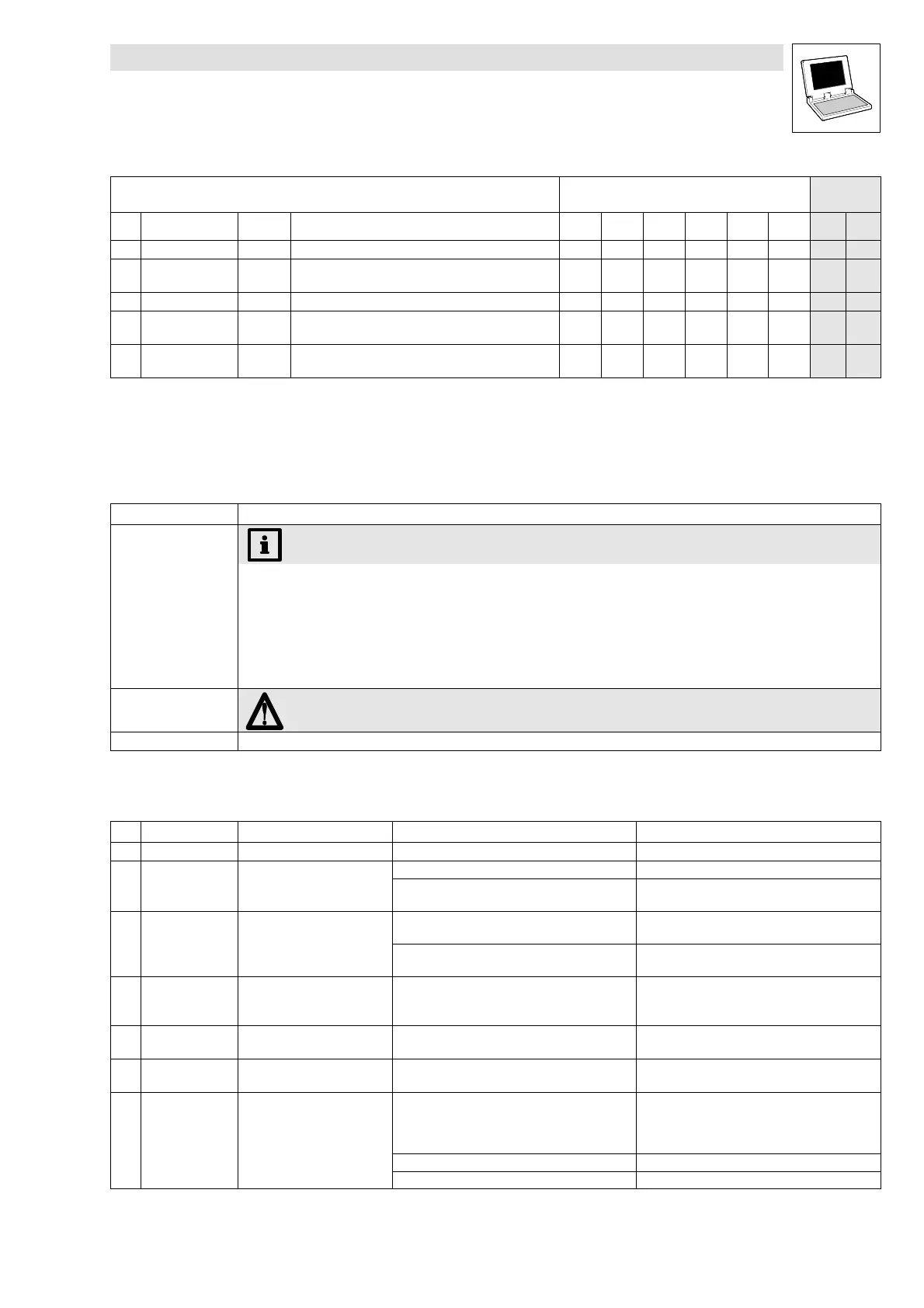

System error message Possible settings/response

• Default setting ü Setting possible

Available in

No. Display Source Meaning

TRIP Message Warning Fault/QSP Off Code Drive

PLC

Servo

PLC

219 overrun Cycl.-T internal Time exceeded in cyclic task (PLC_PRG) • ü ü

1)

ü ü

220 NoT-FktCredit internal Not enough technology units

availabl e in the PLC

• ü ü

230 No Program internal No PLC program loaded • ü ü

240 ovrTransQueue Free CAN

obj.

Free CAN objects

Overflow of send order memory

• ü ü ü

2)

ü C0608 ü ü

241 ovr Receive Free CAN

obj.

Free CAN objects: Too many receive telegrams • ü

2)

C0609 ü

1)

In DDS adjustable under Project WExceptional

response

2)

Only with 9300 Servo PLC

3.3.1 System error message reset

Reaction Measures to reset system error messages

TRIP/FAIL-QSP

A reset of TRIP/FAIL-QSP requires an acknowledgement.

• If the TRIP source is still active, the current TRIP cannot be reset.

A TRIP/FAIL-QSP can be acknowledged by:

• Dialog box ”9300 diagnostics” in GDC ð Press the button “History buffer reset”.

• 9371 BB keypad ð Pressing the STOP key before the RUN key (which enables the PLC again).

• Code C0043 ð Set C0043 = 0

• Control word C0135, bit 11

• Control word AIF1_wDctrlCtrl from SB AIF1_IN

• Control word CAN1_wDctrlCtrl from SB CAN1_IN

• System variable DCTRL_vTripReset_b from SB DCTRL_DriveControl

Message

The message auotmatically disappears after the error has been eliminated, the drive automatically restarts!

Warning The message automatically disappears after the error has been eliminated.

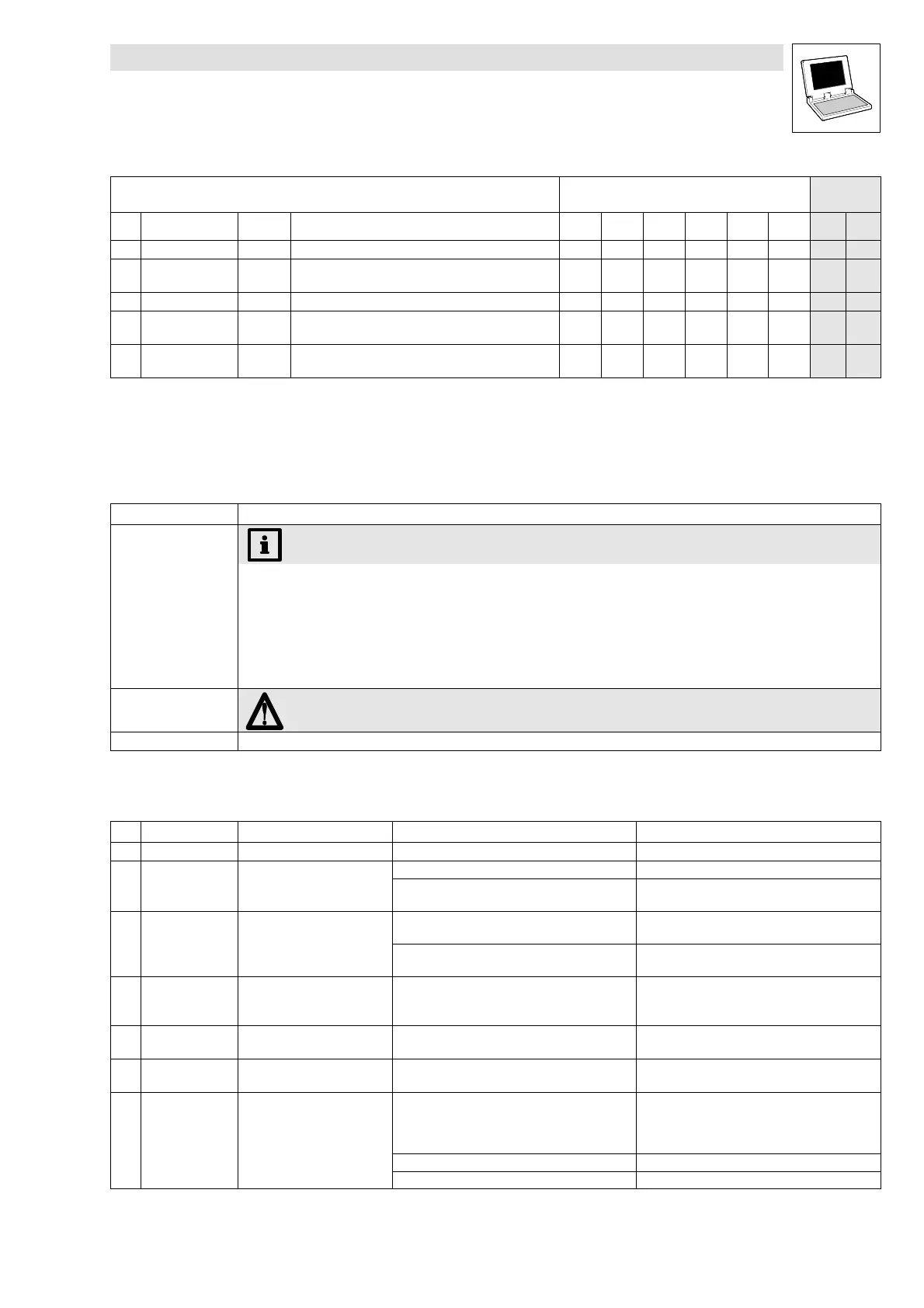

3.3.2 Cause and remedy

No. Display Meaning Cause Remedy

--- --- No fault - -

011 OC1 Motor cable short circuit

Short circuit Find reason for short circuit (check cable)

Excessive capacitive charging current of the motor

cable

Use shorter or lower capacity motor cable

012 OC2 Motor cable earth fault

One of the motor phases contacts earth • Check motor

• Check supply module

Excessive capacitive charging current of the motor

cable

Use shorter or lower capacity motor cable

015 OC5 I x t overload • Frequent and too long acceleration with

overcurrent

• Continuous overload with I

motor

>1.05xI

ratedx

Check drive dimensioning

020 OU Overvoltage

in DC bus

030 LU Undervoltage

in DC bus

DC bus voltage is lower than the value fixed under

C0173

• Check mains voltage

• Check supply cable

050 OH Heat sink temperature higher

than fixed limit temperature

Ambient temperature T

amb

>40°Cor50°C • Allow controller to cool and ensure better

ventilation

• Check ambient temperature in the control

cabinet

Heat sink very dirty Clean the heat sink

Incorrect mounting position Change the mounting position

efesotomasyon.com - Lenze

Loading...

Loading...