6-18

Chapter 6 INSPECTION AND REPAIR OF BASIC ENGINE

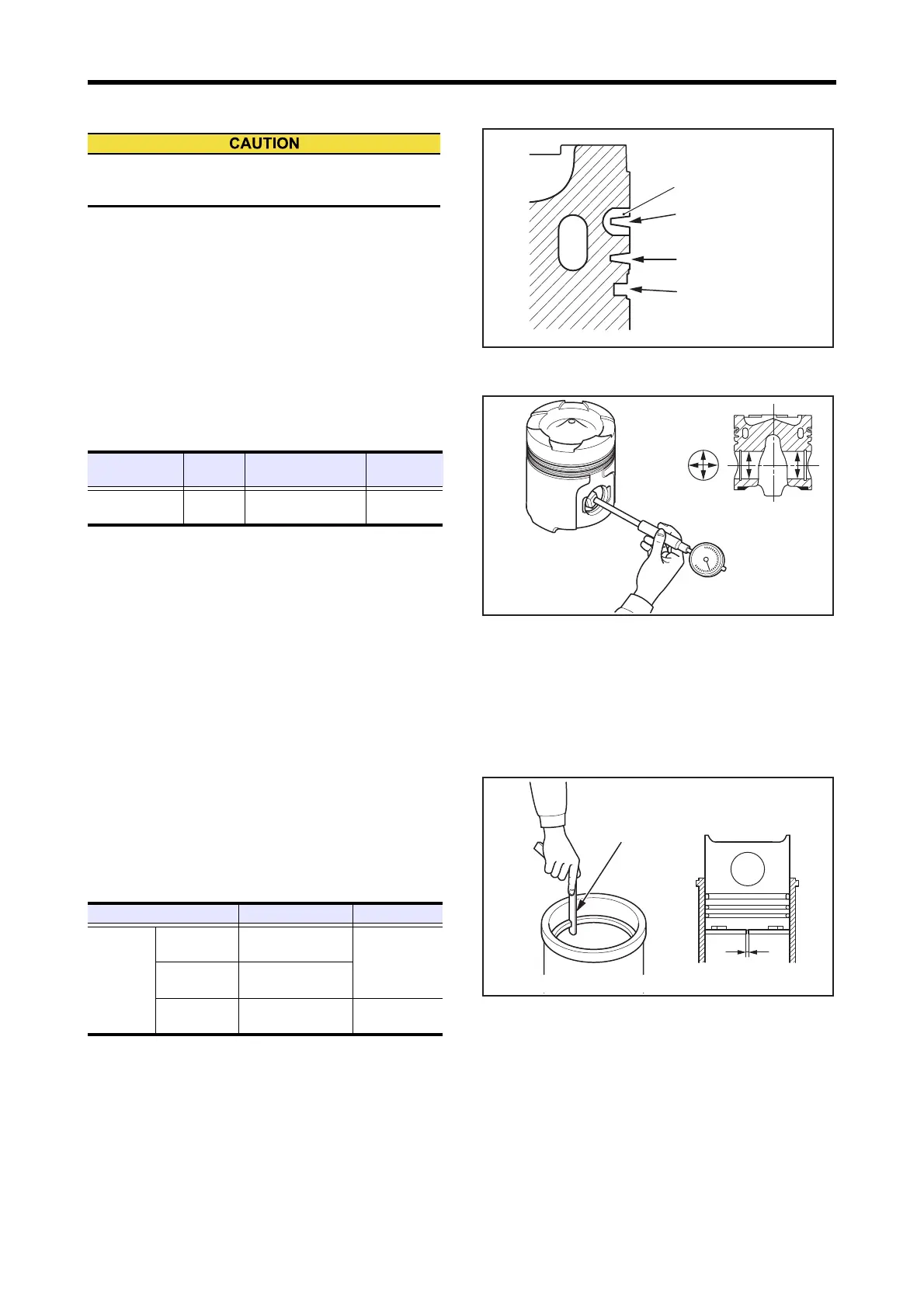

4.4 Piston Ring Groove - Inspect

(1) Remove all deposits such as carbon from each ring

groove.

(2) Visually check each ring groove for wear or damage. If

faulty, replace the piston with a new one. Inspect the

ring insert of No. 1 compression ring groove by dye

penetration test for cracks and separation.

Piston Ring Groove - Inspect

4.5 Piston Pin Bore Inside Diameter - Measure

Measure the piston pin bore inside diameter. If the value

exceeds the limit, replace the piston with a new one.

Piston Pin Bore Inside Diameter - Measure

4.6 Piston Ring - Inspect Visually

Check the sliding surface and top and bottom surfaces for

seizing, abnormal wear, foreign material inclusion and plat-

ing flaking. If any defects are found, replace the piston rings

with new ones.

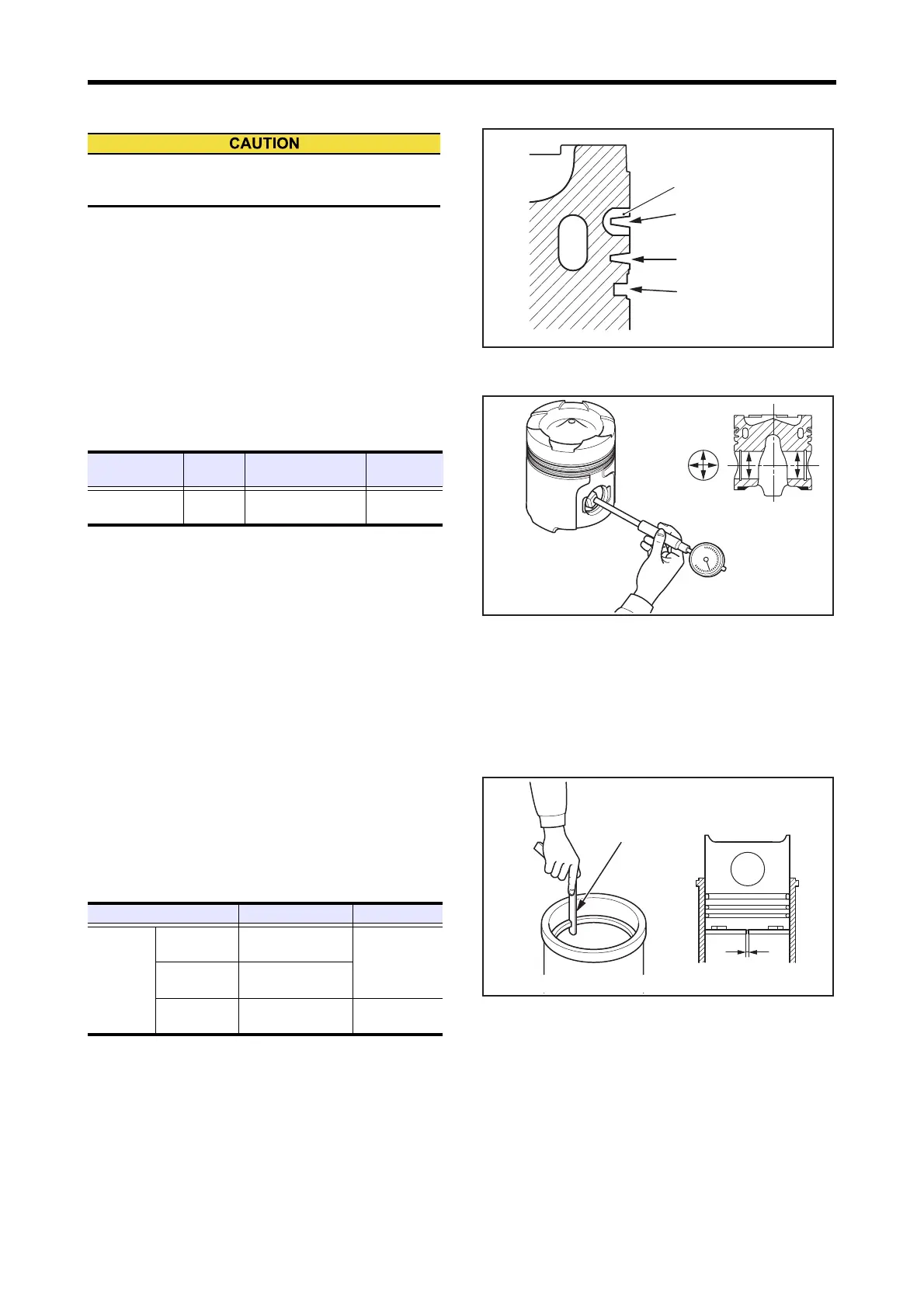

4.7 Piston Ring End Gap - Measure

Place the piston ring in the gauge or a new cylinder liner,

and measure the end gap. If the value exceeds the limit,

replace piston rings with a new set of rings.

Note: Using a piston, push the piston ring squarely into

gauge or cylinder liner.

Piston Ring End Gap - Measure

Remove carbon deposits from piston and inspect the

entire circumference of piston.

Ring insert

No. 1 compression ring

groove

No. 2 compression ring

groove

Oil ring groove

Item

Nominal

value

Standard value Limit value

Piston pin bore

inside diameter

ø70 mm

[2.76 in.]

70.002 to 70.015 mm

[2.7560 to 2.7565 in.]

70.040 mm

[2.7575 in.]

Measurement

direction

Measurement

point

Item Standard value Limit value

Piston ring

end gap

No.1

compression

0.6 to 0.8 mm

[0.024 to 0.032 in.]

1.0 mm

[0.040 in.]

No.2

compression

0.6 to 0.8 mm

[0.024 to 0.032 in.]

Oil

0.3 to 0.45 mm

[0.012 to 0.0177 in.]

0.6 mm

[0.024 in.]

Thickness gauge

Gauge inside diameter: 170 ± 0 mm [6.69 ± 0 in.]

End gap

Loading...

Loading...