13-11

Chapter 13 ADJUSTMENT AND OPERATION

3. Engine-Test and Adjustment

After the break-in operation is completed, and the engine runs normally, check and adjust the performance and functions of the

engine.

Record the test results referring to the engine data of delivery time.

3.1 Engine Performance Test

Fuel consumption rate, various temperatures and pressures, and exhaust color

3.2 Emission Gas Test

Exhaust gas analyses

3.3 Governor Performance Test

Minimum speed at no-load (low idle) - set

Maximum speed at no-load (high idle) - set

Load sudden application and rejection tests

Governor droop, hunting, and rotational fluctuation - check

Setting conditions of governor controller and others - check

3.4 Alarm Action and Emergency Stop Tests

Oil pressure decrease, water temperature increase, and overspeed

3.5 Maximum Fuel Injection Volume - Set

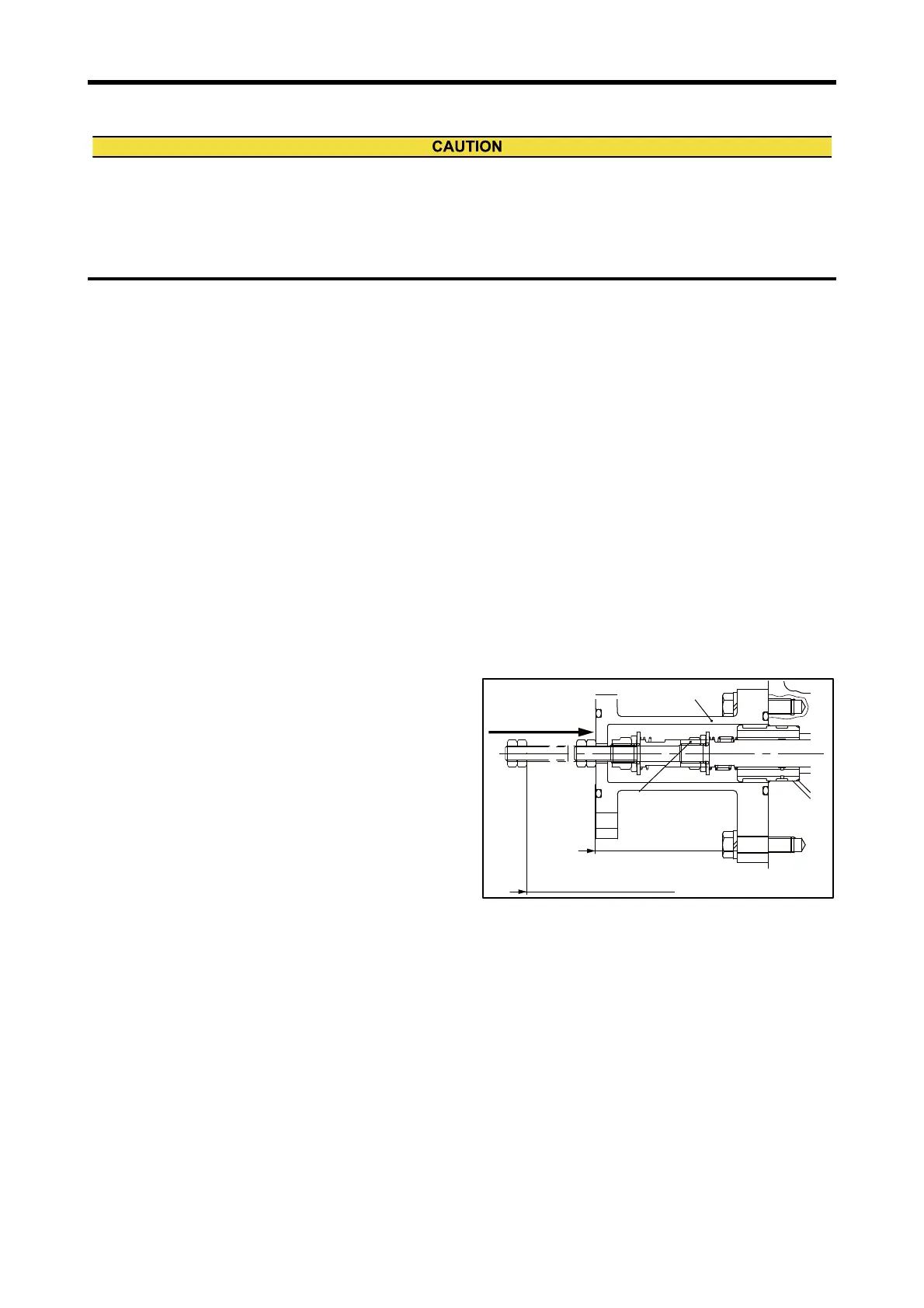

(1) Remove the rack set cap at the front end of fuel injec-

tion pump, and apply the rated (maximum) load.

(2) Secure the double nuts when the nuts at the rack end

comes into contact with the spring case end face.

Maximum Fuel Injection Volume - Set

(a) Engine test, adjustment and seal shall be performed at the certified maintenance shop only.

When the seal of engine is to be done at a service shop other than the certified shops, ask a certified shop for

the presence of qualified person for the test, adjustment and seal.

(b) Performance check and adjustment of the engine shall be conducted when the water and oil temperatures

become stable after sufficient warm-up operation.

Fuel injection

volume increase

Fuel injection pump rack zero position

Spring case

Fuel injection

volume increase

Rack position at maximum load

Rack position at maximum load

Rack position at maximum load

Spring case

33 ± 3.3 N·m

{3.37 ± 0.34 kgf·m}

[24.3 ± 2.43 lbf·ft]

Loading...

Loading...