2-18

Chapter 2 SERVICE DATA

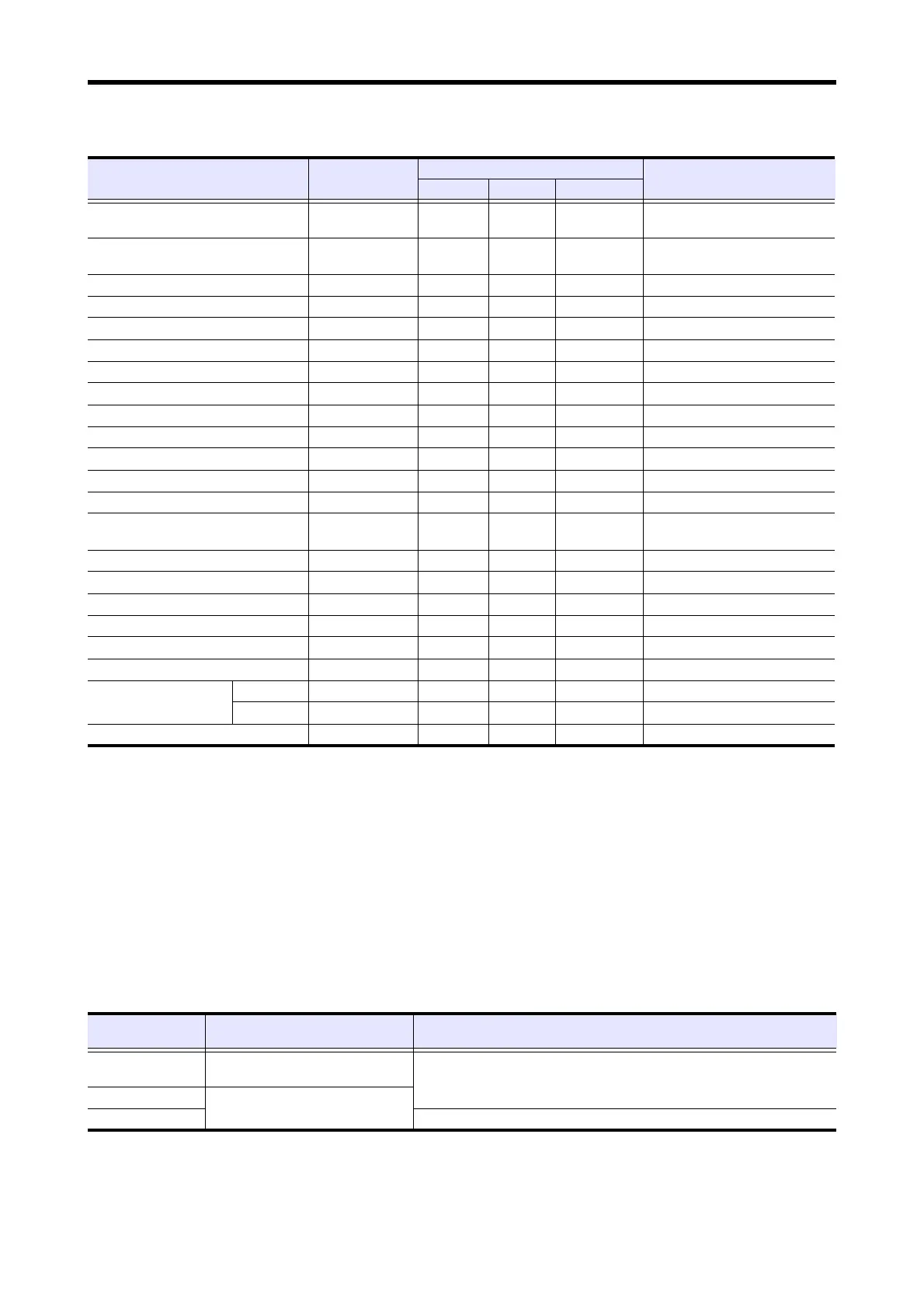

2. Tightening Torque Table

2.1 Tightening Torque Spec for Basic Engine

Note:(a) For torque-angle tightening method of cylinder head bolts, follow the steps in sequence given below:

1) Tighten the bolts with a snug torque of 294 ± 14.7 N·m {30 ± 1.5 kgf·m} [217±11 lbf·ft].

2) Tighten to the angle 65± 3°.

3) Loosen all bolts, and then retighten them in the sequence shown in the above 1) and 2).(2-time tightening)

For tightening procedure, refer to "Cylinder Head Bolt - Tighten" of "ASSEMBLY OF BASIC ENGINE".

(b) Tighten the main bearing cap bolt in specified sequence. Tighten them to the half of specified torque, then tighten them

to the specified torque.

For tightening procedure, refer to "Main bearing cap - Install" of "ASSEMBLY OF BASIC ENGINE."

(c) Tighten piston cooling nozzle check valves to the specified torque. Do not over-tighten. If the tightening torque exceeds

the specified torque, it could cause the check valve to malfunction, which may result in piston seizure.

(d) When [Wet] is indicated, apply engine oil to the threads and bolt seat surface.

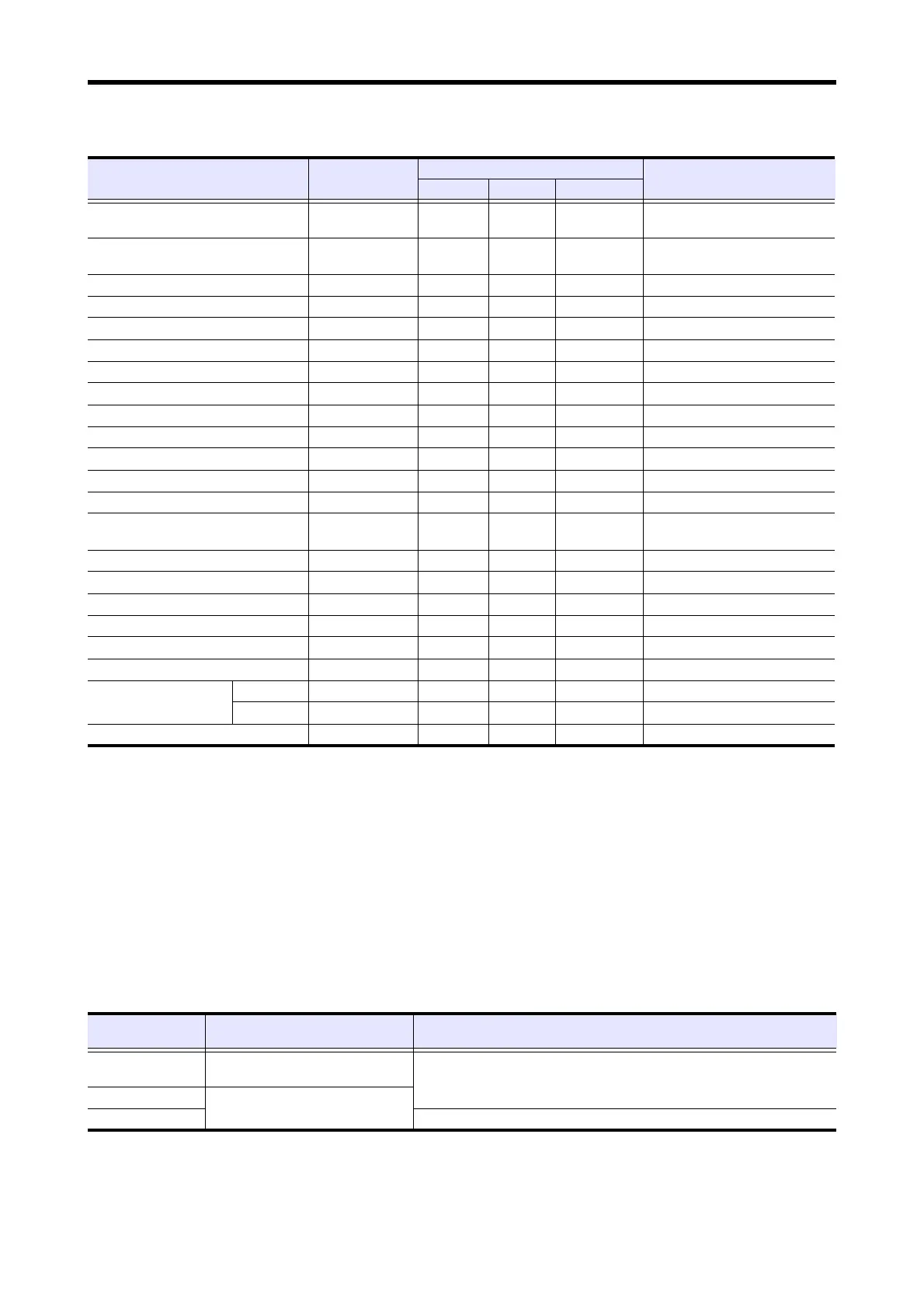

(e) Connecting rod cap bolts should be tightened as shown below.

Description

Dia x Pitch

(M-thread)

Tightening torque

Remarks

N·m kgf·m lbf·ft

Cylinder head bolt M 22 × 2.5 539 ± 27 55 ± 2.75 397.55 ± 19.91

[Wet] 2-time tightening method,

Note (a)

Cylinder head nozzle gland (studs) M 14 × 2.0 73.5 ± 4.5 7.5 ± 0.5 54.21 ± 3.31

Apply Loctite 272 to the internal

screw thread of the cylinder head

Rocker case M 12 × 1.25 108 ± 5.4 11 ± 0.55 79.66 ± 3.98

Rocker shaft M 14 × 2.0 147 ± 7.4 15 ± 0.75 108.42 ± 5.45

Rocker arm (lock nut) M 12 × 1.25 64 ± 3.2 6.5 ± 0.33 47.20 ± 2.36

Bridge (lock nut) M 10 × 1.25 55 ± 2.8 5.6 ± 0.28 40.57 ± 2.06

Camshaft gear M 14 × 1.5 176 ± 8.8 17.9 ± 0.9 129.81 ± 6.49 Use 12T bolt w/hard washer

Camshaft thrust plate M 12 × 1.25 59 ± 5.9 6 ± 0.6 43.52 ± 4.35

Main bearing cap M 22 × 2.5 490 ± 24.5 50 ± 2.5 361.41 ± 18.07 [Wet], Note (b)

Hanger M 12 × 1.25 108 ± 5.4 11 ± 0.55 79.66 ± 3.98

Piston cooling nozzle M 12 × 1.75 34 ± 1.7 3.5 ± 0.18 25.08 ± 1.25 Note (c)

Timing gear case M 16 × 1.5 255 ± 12.8 26 ± 1.3 188.08 ± 9.44 Use hard washer

Rear plate M 12 × 1.25 108 ± 5.4 11 ± 0.55 79.66 ± 3.98

Front mounting bracket M 12 × 1.25 108 ± 5.4 11 ± 0.55 79.66 ± 3.98

Front end lower bolt of right front

mounting bracket only

Rear mounting bracket M 16 × 1.5 216 ± 10.8 22 ± 1.1 159.31 ± 7.96

Connecting rod cap M 22 × 1.5 Note (e) [Wet]

Flywheel M 22 × 1.5 539 ± 27 55 ± 2.75 397.54 ± 19.91 [Wet]

Damper M 22 × 1.5 490 ± 24.5 50 ± 2.5 361.40 ± 18.07

Idler shaft M 12 × 1.25 108 ± 5.4 11 ± 0.55 79.66 ± 3.98 Apply MOLYKOT

Idler shaft thrust collar (nut) M 18 × 1.5 196 ± 9.8 20 ± 1.0 144.56 ± 7.22

Fuel injection

Accessory drive

Case M 12 × 1.25 108 ± 5.4 11 ± 0.55 79.66 ± 3.98

Gear (nut) M 30 × 1.5 490 ± 24.5 50 ± 2.5 361.40 ± 18.07

Governor drive case M 12 × 1.25 108 ± 5.4 11 ± 0.55 79.66 ± 3.98

Bolt mark

Torque method

(2-time tightening method)

Angle controlled method (2-time tightening method)

2

539 ± 27 N·m {55 ± 2.75 kgf·m}

[398 ± 20 lbf·ft]

Snug torque 245 ± 12.3 N·m {25 ± 1.25 kgf·m} [180 ± 9 lbf·ft] → 60 ± 3°

AU

637 ± 31.9 N·m {65 ± 3.25 kgf·m}

[470 ± 24 lbf·ft]

AL Snug torque 294 ± 14.7 N·m {30 ± 1.5 kgf·m} [217 ± 11 lbf·ft] → 60 ± 3°

Loading...

Loading...