6-31

Chapter 6 INSPECTION AND REPAIR OF BASIC ENGINE

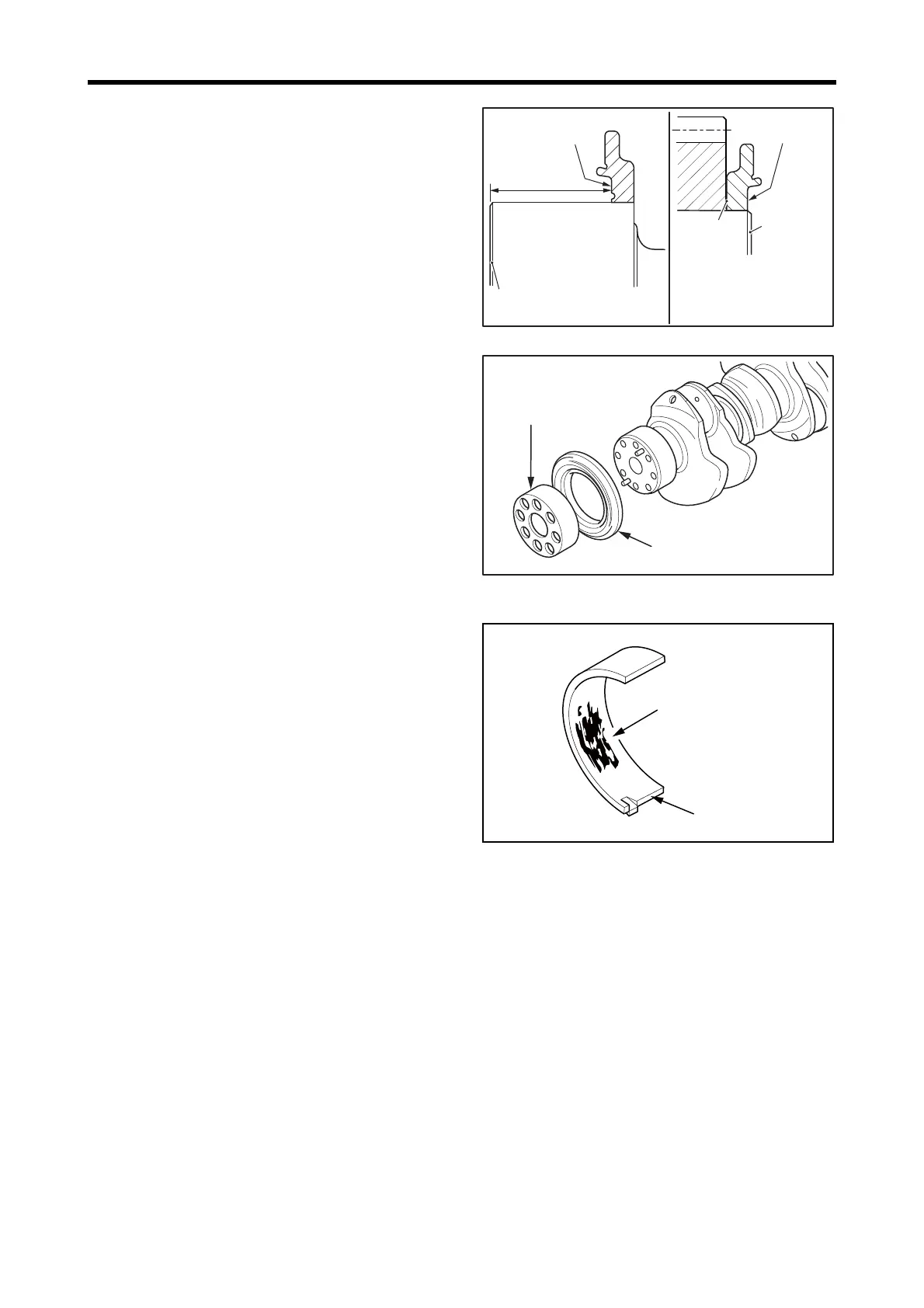

5.11.2 Oil Seal Slinger - Install

(1) Measure the outside diameter of crankshaft and inside

diameter of oil seal slinger, and check the interference.

(2) Heat the oil seal slinger evenly to the temperature of

110ºC [230°F] or less. After checking the correct direc-

tion and position of slinger, install the slinger.

Oil Seal Slinger - Install

Front Oil Seal Slinger - Install

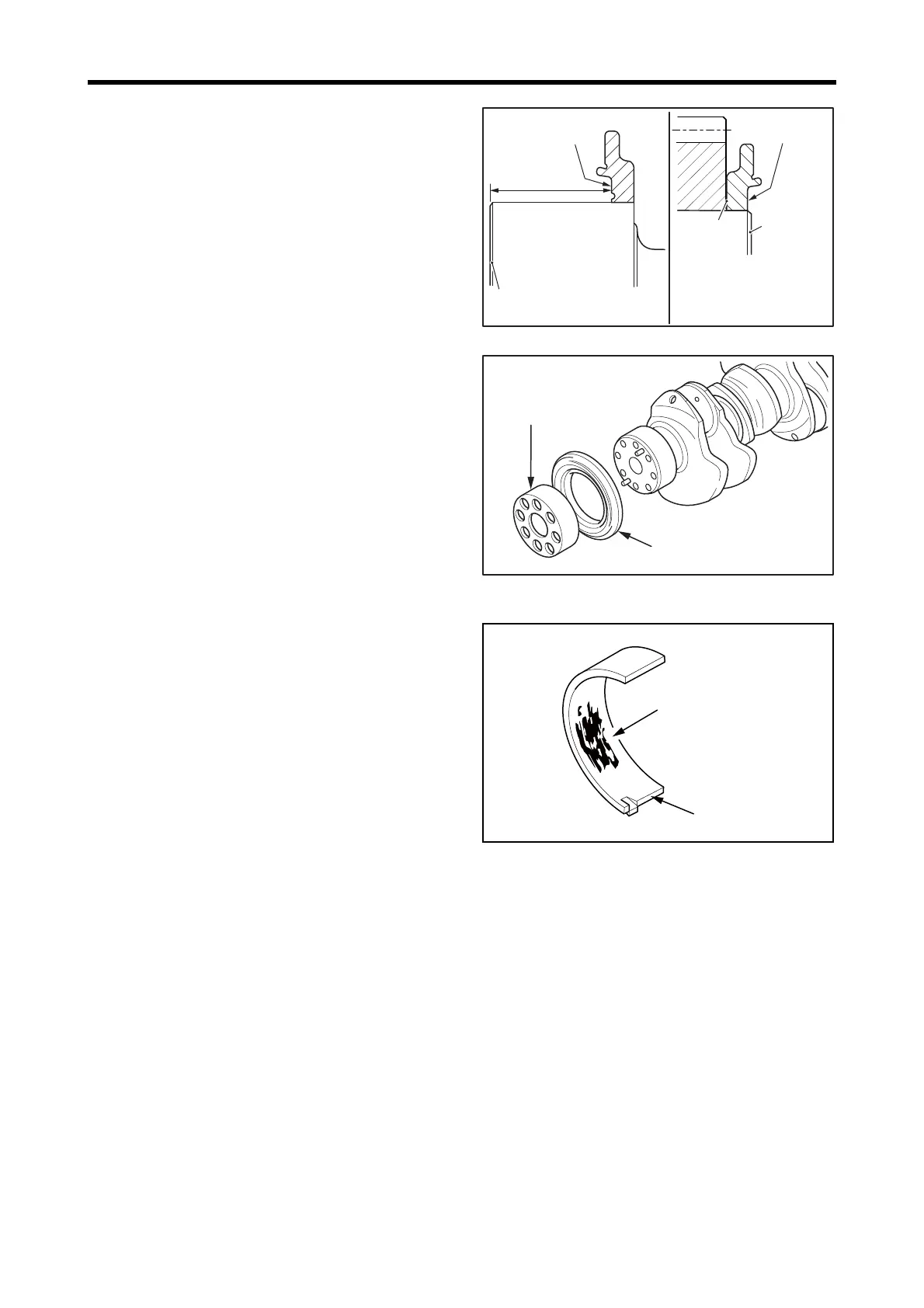

5.12 Main Bearing - Inspect

Inspect the sliding surface, back surface and end surface of

main bearing. If any defect such as local contact, sliding

scratches, corrosion and foreign material inclusion is found,

replace the main bearing with a new one.

Main Bearing - Inspect

ID mark

(37425-08201)

Crankshaft front end

46.5 mm

[1.83 in.]

Front

Tight contact

with gear

Crankshaft

rear end

Rear

ID mark

(37111-14200)

Interference standard

value: 0.210 to 0.294 mm

[0.0083 to 0.0116 in.]

Interference standard

value: 0.210 to 0.294 mm

[0.0083 to 0.0116 in.]

Front slinger insert

P/N:37591-03900

Front oil seal slinger

Flaw, corrosion, peeling

End face

Loading...

Loading...