11-16

Chapter 11 INLET AND EXHAUST SYSTEMS

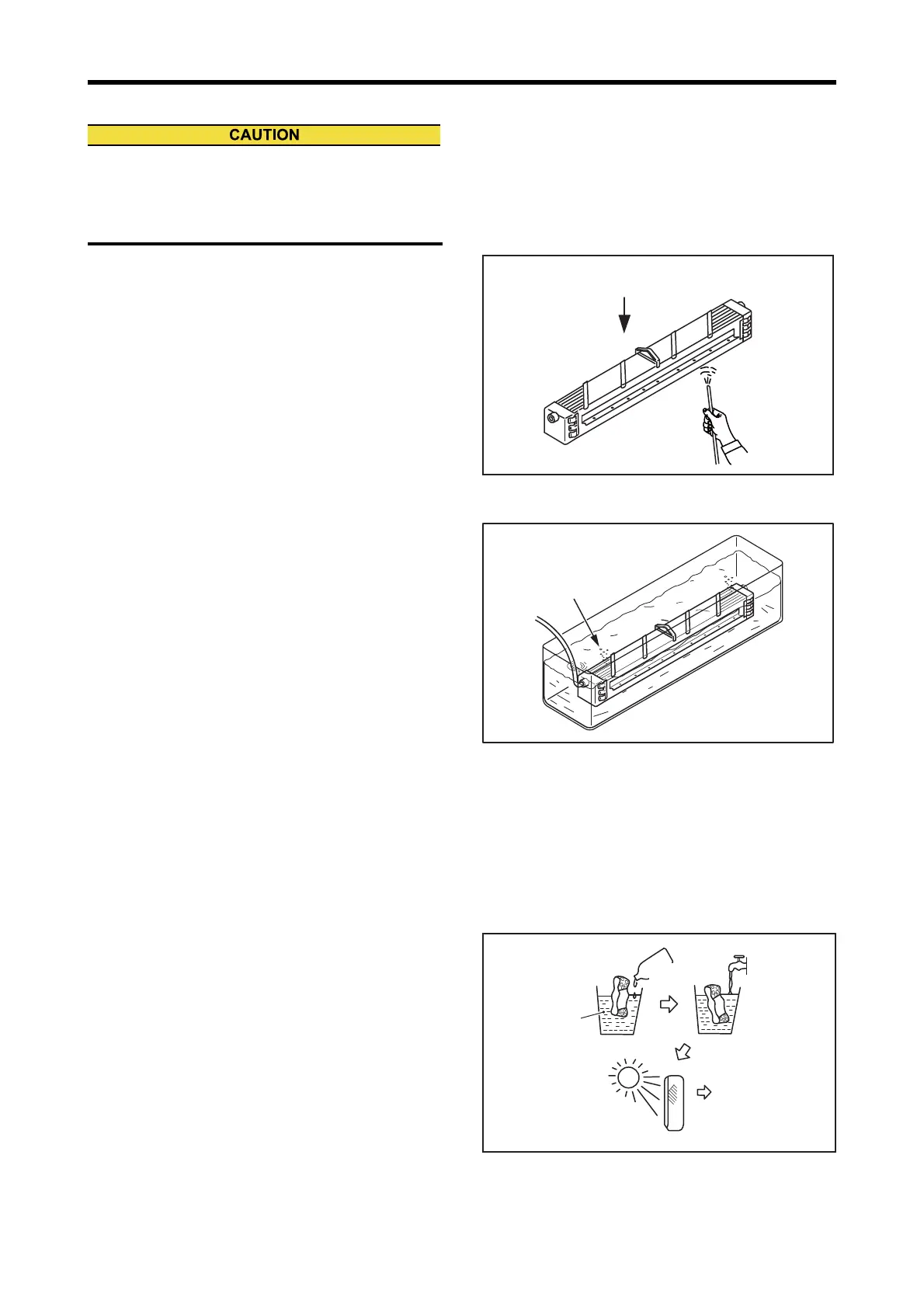

2.1.1 Air Cooler - Inspect

2.1.2 Air Cooler - Clean

Blow compressed air (at a pressure of 0.29 to 0.49 MPa {3

to 5 kgf/cm

2

} [43 to 71 psi] or less) through the air cooler in

the opposite direction to the normal air flow to remove the

accumulation of dust and dirt. Then, inspect for corrosion

and cracks.

Air Cooler - Clean

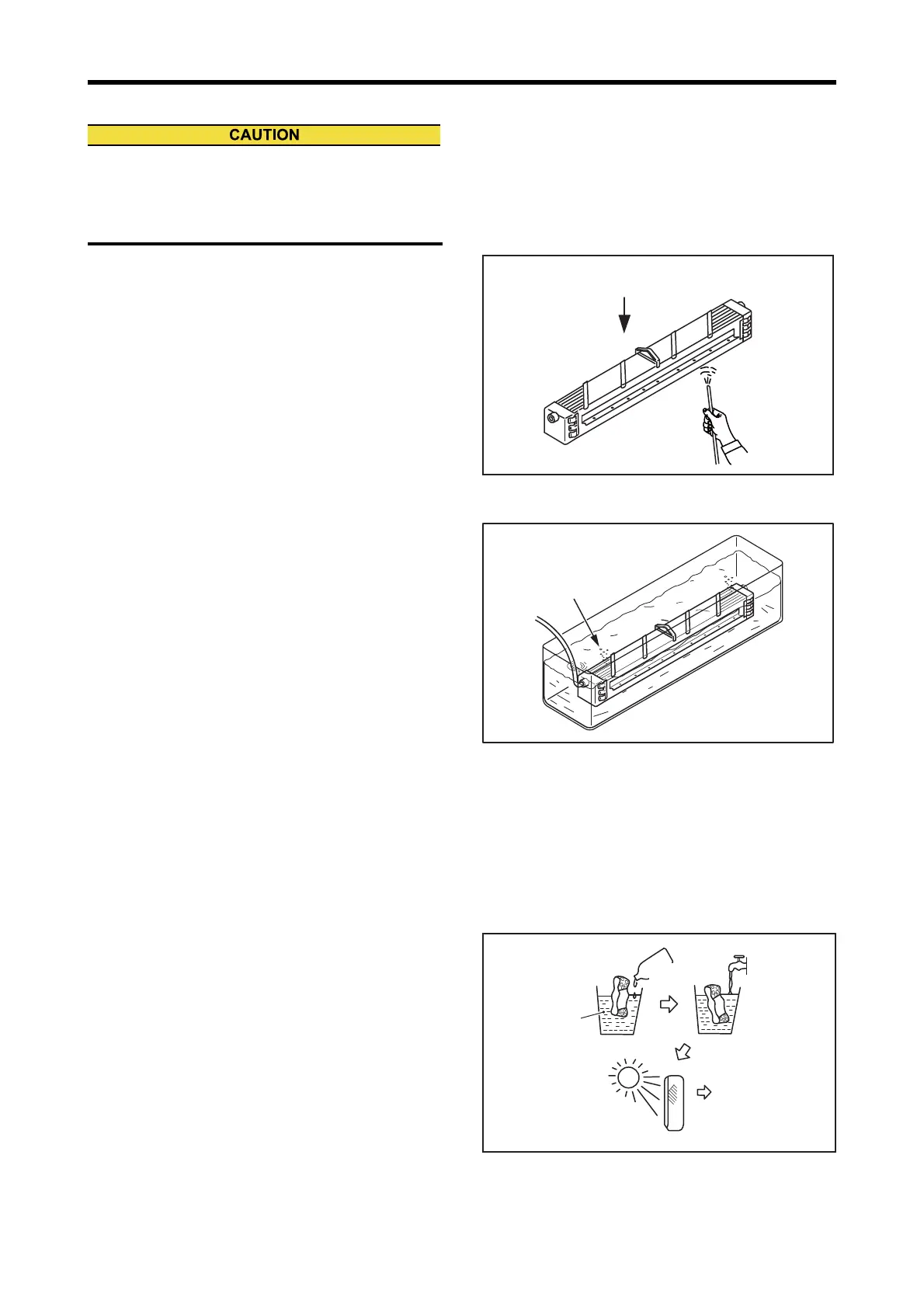

2.1.3 Air Cooler - Inspect for Leakage

Immerse the air cooler in water. In this condition, blow

compressed air (at a pressure of 0.39 MPa {4 kgf/cm

2

} [57

psi]) to the coolant passage to check for air leakage.

Air Cooler - Inspect for Leakage

2.1.4 Air Cooler - Assemble

To assemble, follow the disassembly sequence in reverse.

Seal the clearance between the element and plate with

KE45-W (Shin-Etsu Chemical Co., ltd.) or equivalent sili-

cone sealant.

2.2 Pre-cleaner - Clean

(1) Remove the pre-cleaner from the silencer, and hand-

wash the pre-cleaner using neutral detergent.

(2) Rinse with fresh water.

(3) Dry it thoroughly, and install it to the silencer.

Note: If the pre-cleaner is damaged or torn, replace it with a

new one.

Pre-cleaner - Clean

The air cooler differs in material and structure depend-

ing on the application (fresh water or seawater). Pay

attention to the difference when handling the air

cooler. This cooler is for fresh water.

Intake side

Compressed air

Air leakage

(Wash)

(Rinse)

Water

Install

(Dry)

Mild

detergent

Loading...

Loading...