6-6

Chapter 6 INSPECTION AND REPAIR OF BASIC ENGINE

1.7 Valve Seat - Reface

If any damage or inclusions are found, grind the sheet face.

(1) Reface the valve seat with valve seat cutter or valve

seat grinder. After refacing, insert sand paper of approx

400 grit between cutter and valve, and glind valve seat

lightly.

If the seat width exceeds the standard, grind the valve

inner seat with 44°50′ valve seat cutter.

(2) Lap the valve and valve seat.

Note:(a) Valve seat refacing depth is to be minimal.

(b) If the seat width cannot be repaired to the standard

value, or line contact on valve seat outer periphery

is shown, replace the valve seat with a new one.

(c) If the valve sinkage exceeds the specified limit after

refacing, replace the valve seat with a new one.

Valve Seat - Reface

1.8 Valve Seat - Replace

Be careful not to damage the machined surface of cylinder

head when removing the valve seat.

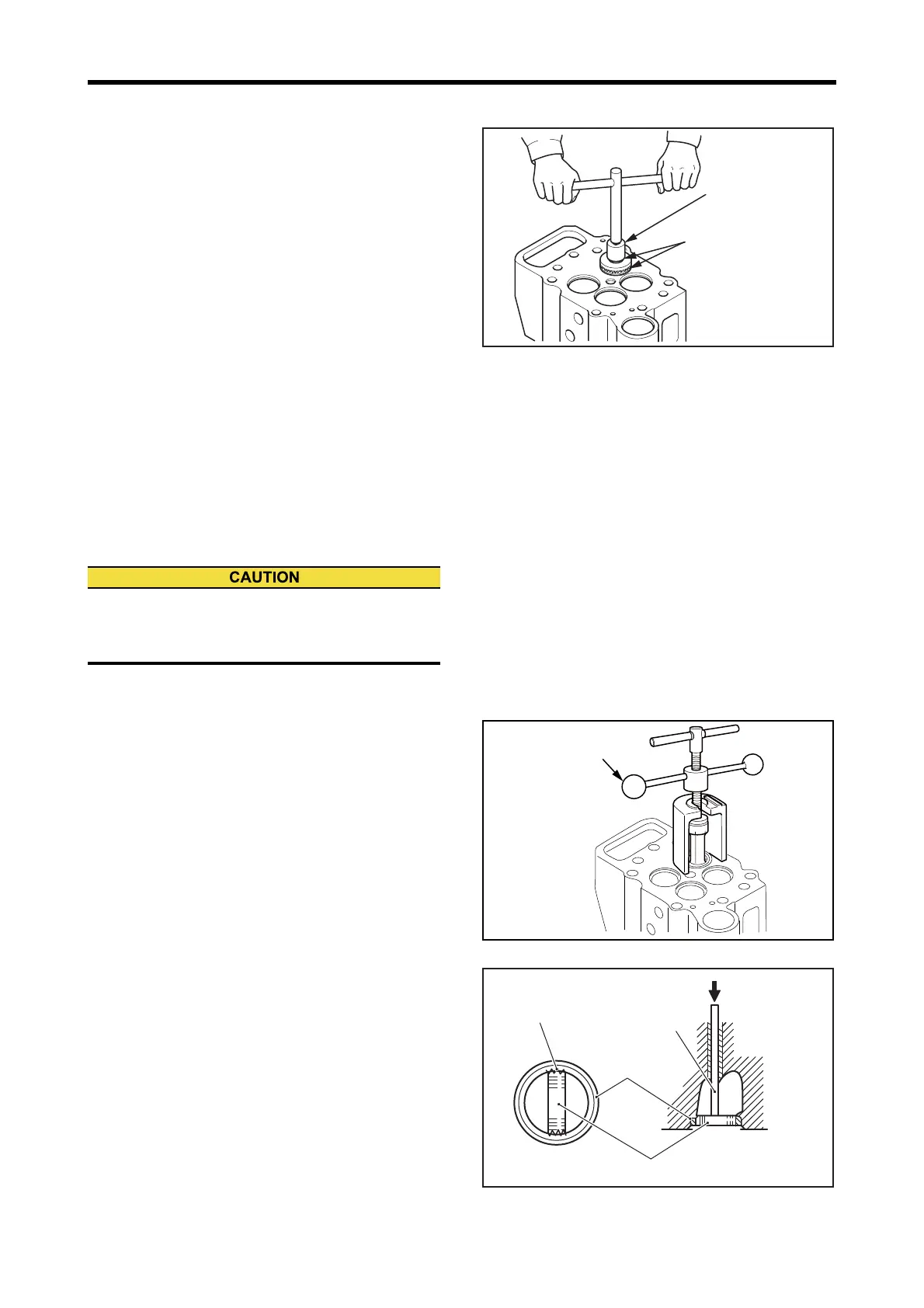

1.8.1 Valve Seat - Remove (With Valve Seat Puller)

Remove the valve seat with valve seat puller.

Valve Seat - Remove (With Valve Seat Puller)

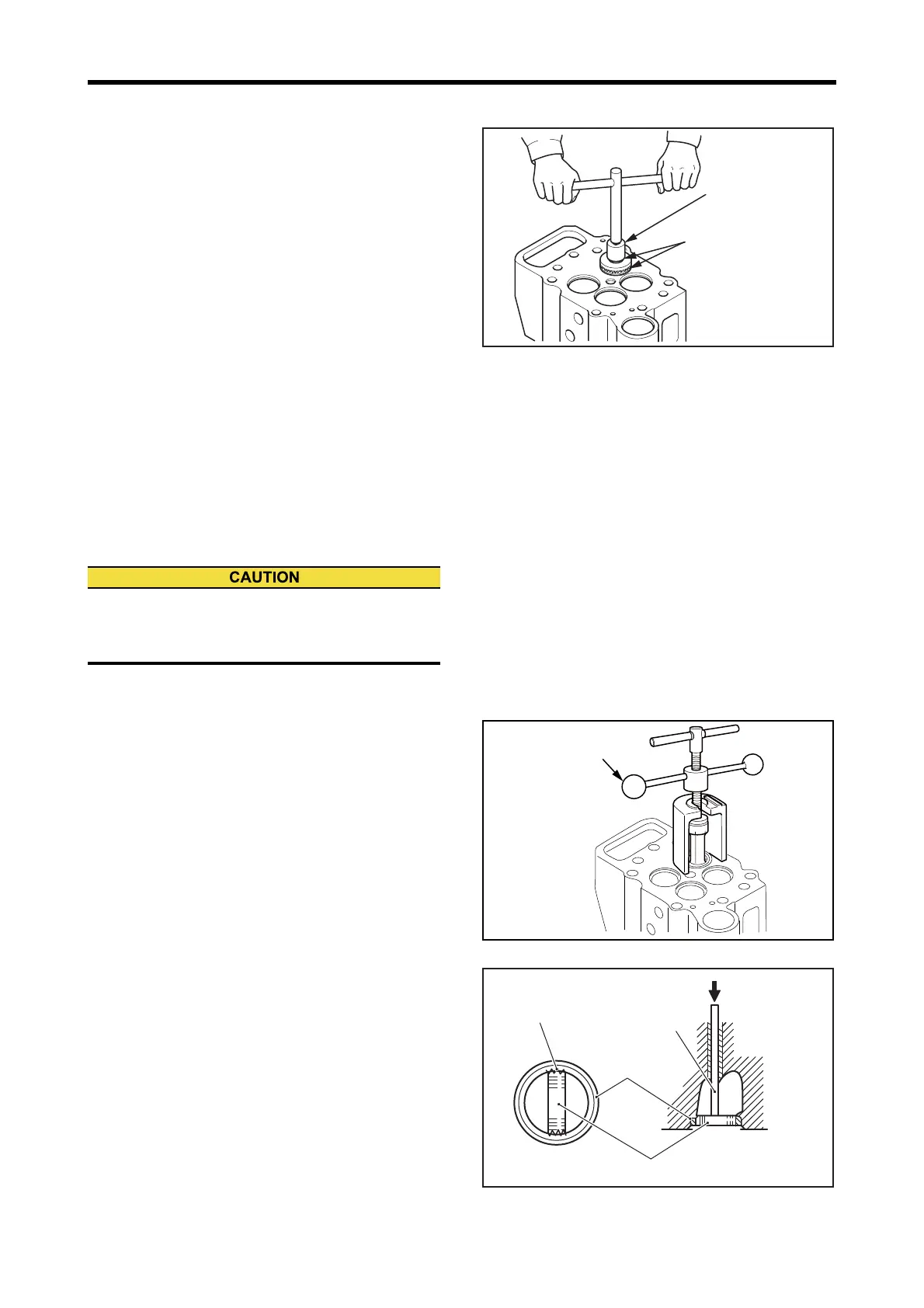

1.8.2 Valve Seat - Remove (by Welding)

To remove the valve seat, weld a stud to valve seat as

shown. Then, insert a shaft into valve guide hole from the

top of cylinder head, and punch out the valve seat with

shaft.

Note: Be careful not to allow spatters to adhere to the ma-

chined surface of the cylinder head during welding.

Valve Seat - Remove (by Welding)

Valve seat cutter

P/N: 37591-06400

37591-06430

Socket

(width across flats

32 mm [1.26 in.])

Select the valve seat with appropriate interference.

Improper interference can result in dropping out of

valve seat or crack in cylinder head.

Valve seat puller

P/N:32591-04200

Valve seat

Stud, etc.

Welding

Shaft

Loading...

Loading...