5-22

Chapter 5 DISASSEMBLY OF BASIC ENGINE

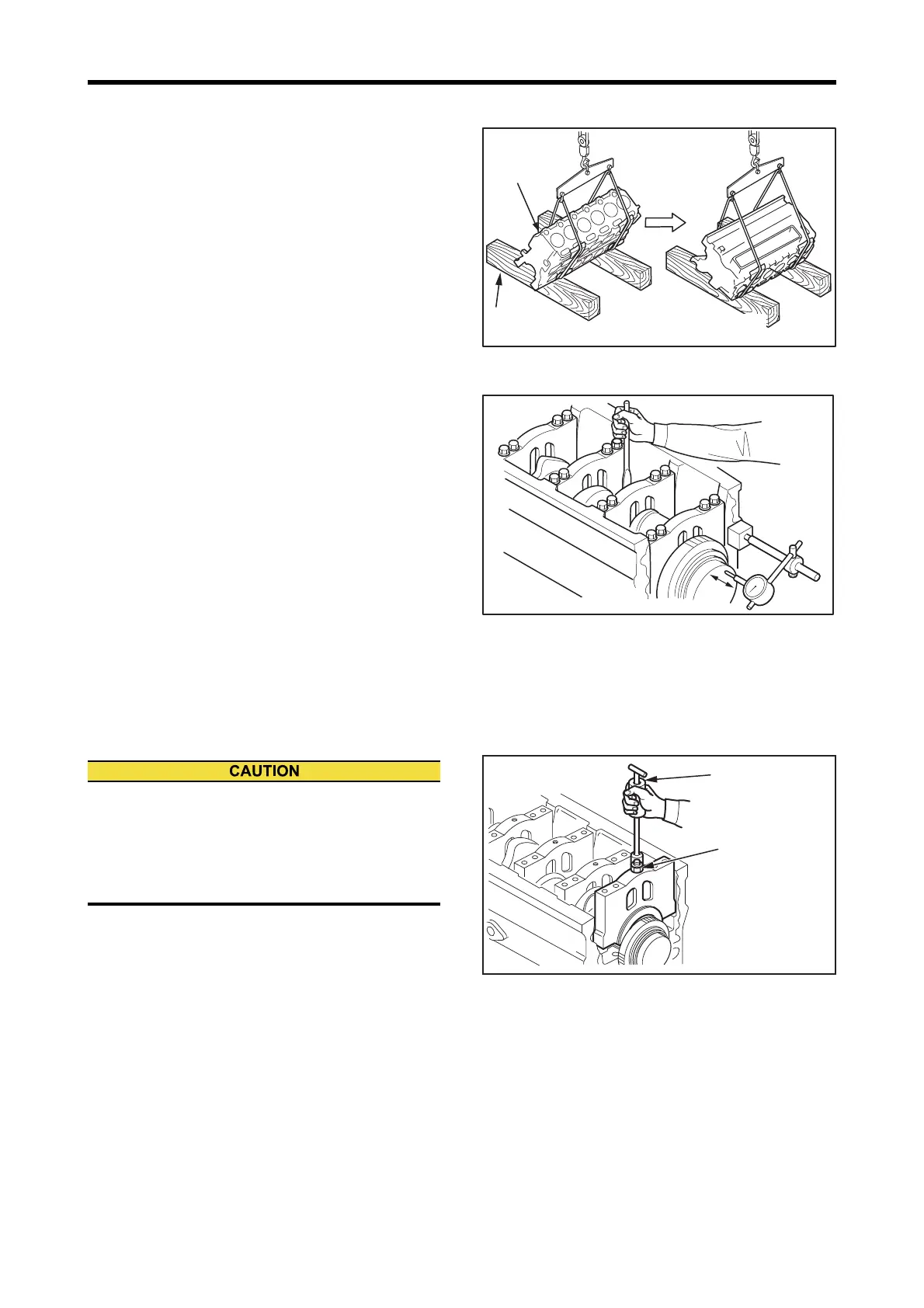

5.1 Crankcase - Turn Over (Upend)

Using a turnover machine, turn over the crankcase. When

the turnover machine is not available, hitch slings to the

crankcase using wood pieces and cloth pads, and raise the

crankcase with a hoist or crane. Then lay it on the wooden

block with its side facing downward. Then, change the posi-

tions of the slings, and turn over to upend the crankcase.

Crankcase - Turn Over (Upend)

5.2 Crankshaft End Play - Measure

Measure the crankshaft end play, and know the current con-

dition.

For the measurement procedure, refer to "Crankshaft End

Play - Measure" of "ASSEMBLY OF BASIC ENGINE."

Crankshaft End Play - Measure

5.3 Piston Cooling Nozzle - Remove

Remove the piston cooling nozzle from the crankcase.

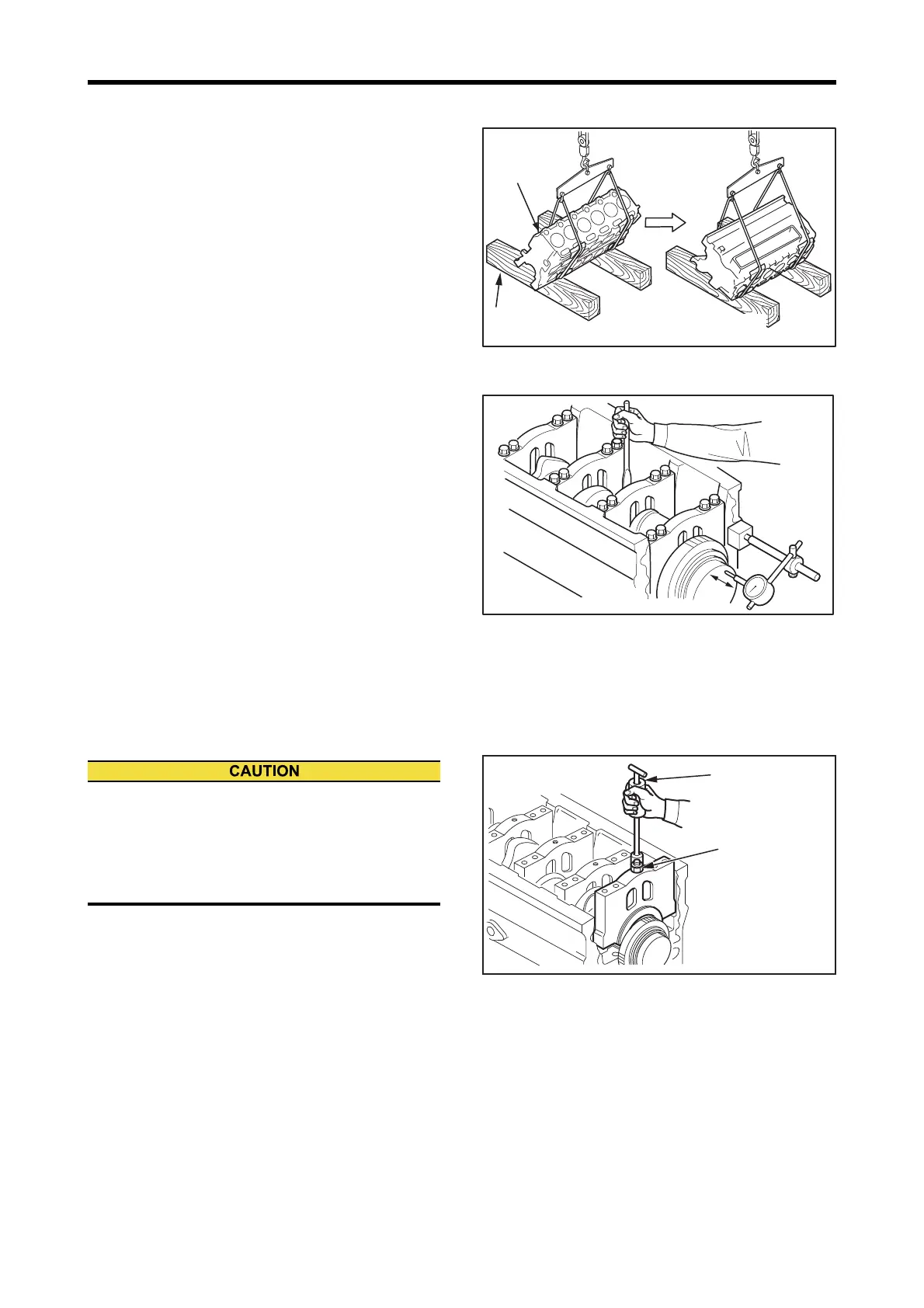

5.4 Main Bearing Cap - Remove

(1) Remove the main bearing cap bolt.

(2) Install the adapter to main bearing cap.

(3) Install the nozzle remover to adapter.

(4) Remove the main bearing cap from crankcase.

(5) Remove the lower main bearing from the main bearing

cap.

(6) Remove the lower thrust plate from the rearmost main

bearing cap.

Main Bearing Cap - Remove

Crankcase

rotation direction

Crankcase

Wood block

Crankcase weight:

approx

530 kg [1168 lb] (S6R)

approx

590 kg [1301 lb] (S6R2)

When removing the main bearing cap, be careful not

to damage the lower main bearing or the lower thrust

plate attached to the cap. Also be careful not to drop

those parts from the cap, which may result in crank-

shaft damage.

Adapter

P/N:37591-04300

(M10 × 1.25 mm)

Nozzle remover

P/N:33591-10101

Loading...

Loading...