7-3

Chapter 7 ASSEMBLY OF BASIC ENGINE

Chapter 7 ASSEMBLY OF BASIC ENGINE

1. Crankshaft and Main Bearing - Install

1.1 Crankcase - Turn Over (Upend)

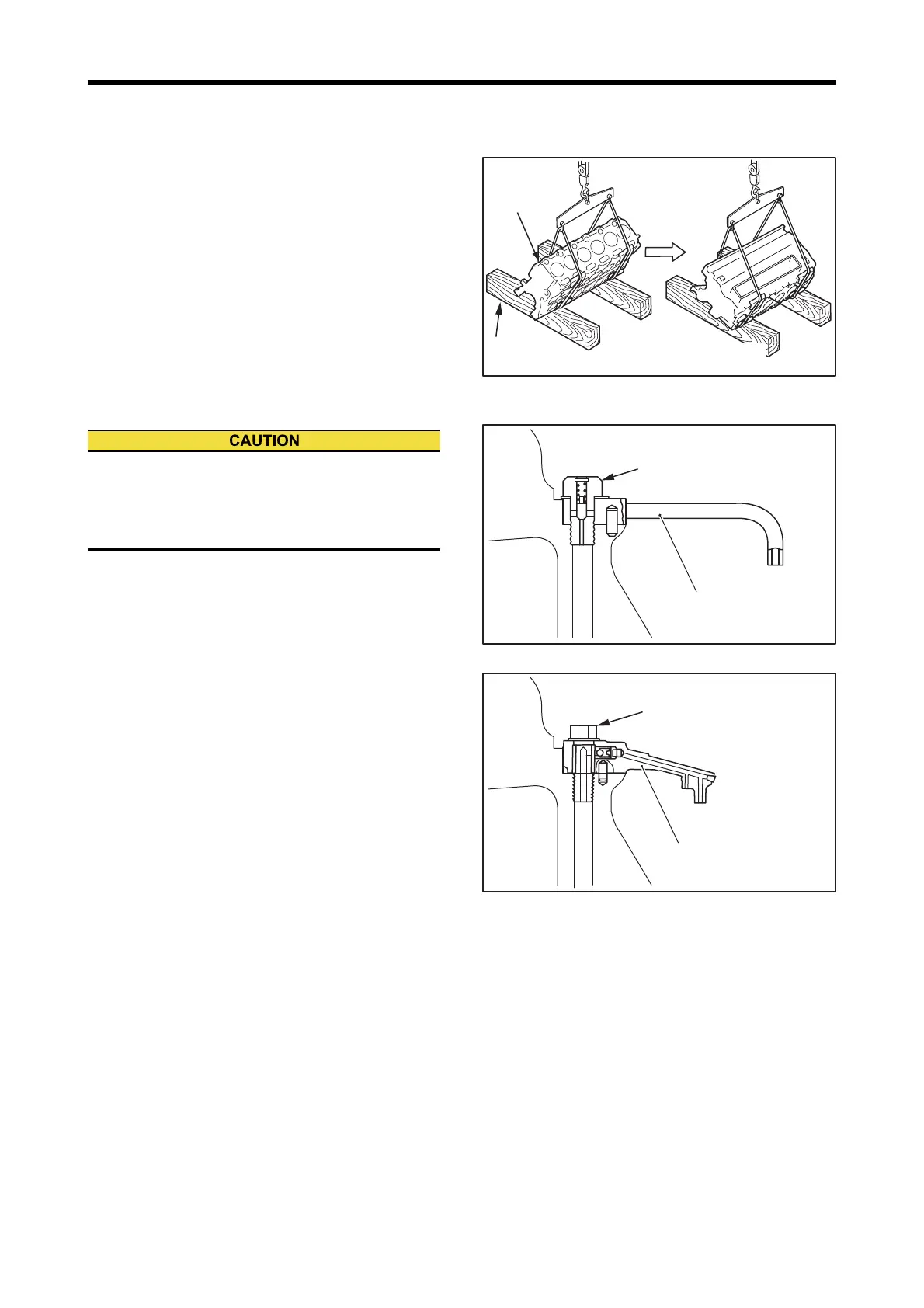

Using a turnover machine, turn over the crankcase. When

the turnover machine is not available, hitch slings to the

crankcase using wood pieces and cloth pads, and raise the

crankcase with a hoist or crane. Then lay it on the wooden

block with its side facing downward. Then, change the posi-

tions of the slings, and turn over to upend the crankcase.

Crankcase - Turn Over (Upend)

1.2 Piston Cooling Nozzle - Install

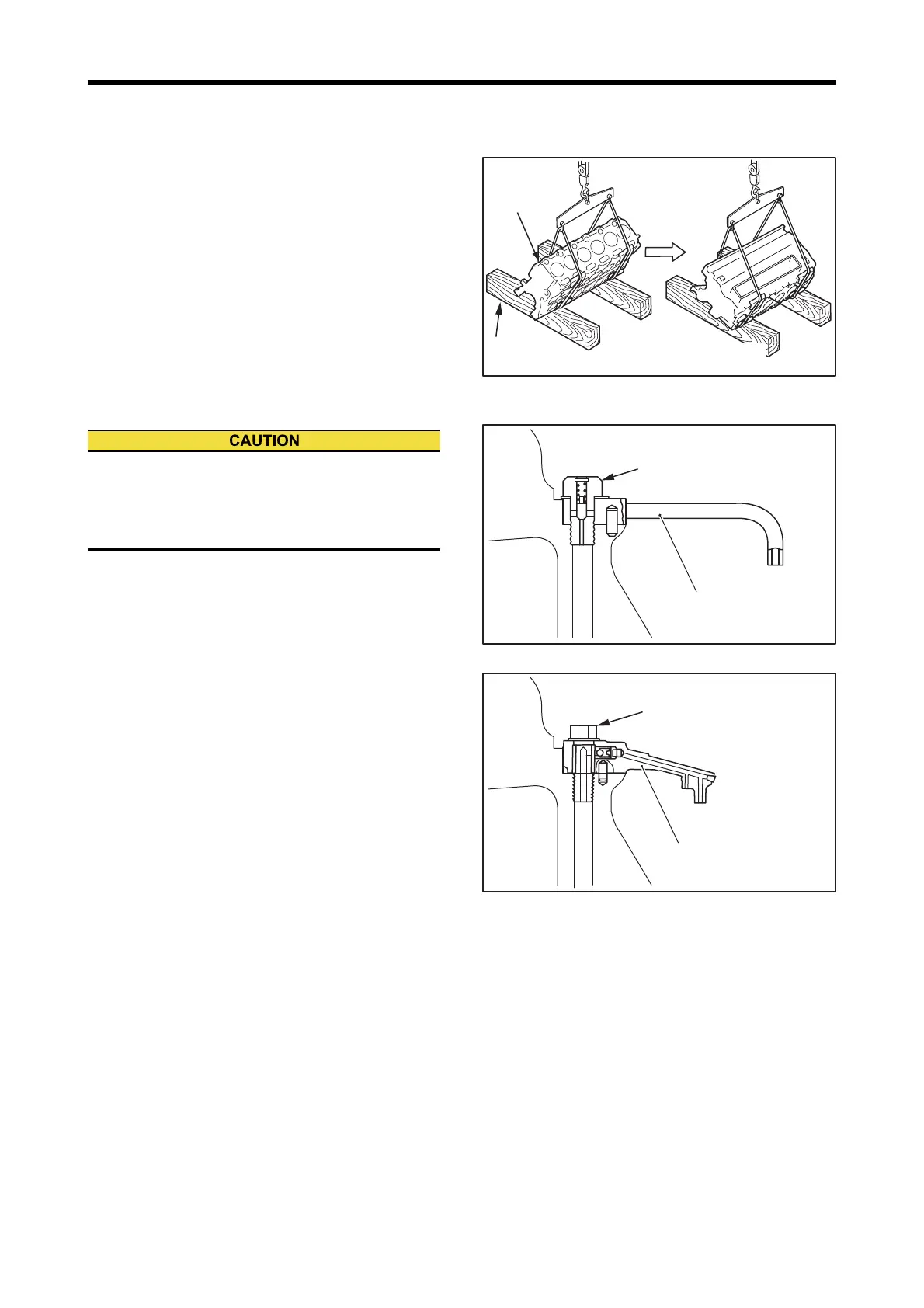

Install the piston cooling nozzle into the crankcase and

tighten the eye bolt or check valve to the specified torque.

Piston Cooling Nozzle - Install (One Jet Spec)

Piston Cooling Nozzle - Install (Two Jet Spec)

Crankcase

rotation direction

Crankcase

Wood block

Crankcase weight:

approx

530 kg [1168 lb] (S6R)

approx

590 kg [1301 lb] (S6R2)

Be sure to tighten the piston cooling nozzle to the

specified torque using a torque wrench. If the nozzle is

over-tightened, it may cause the valve malfunction,

and lead to piston seizure.

34 ± 1.7 N·m

{3.5 ± 0.18 kgf·m}

[25 ± 1.25 lbf·ft]

Piston cooling nozzle

34 ± 1.7 N·m

{3.5 ± 0.18 kgf·m}

[25 ± 1.25 lbf·ft]

Piston cooling nozzle

Loading...

Loading...