7-23

Chapter 7 ASSEMBLY OF BASIC ENGINE

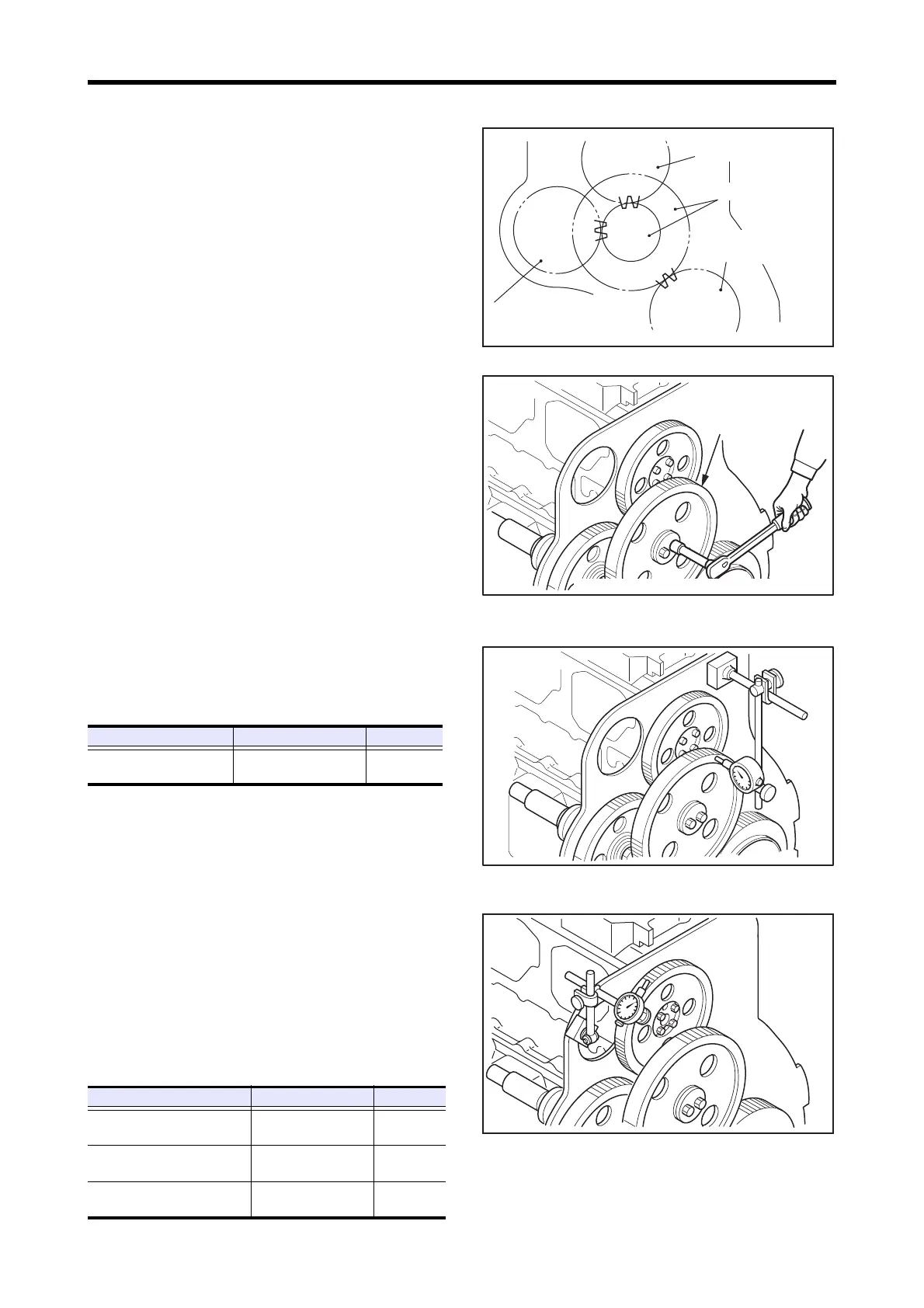

4.7 Idler Gear - Install

(1) Turn the crankshaft to move the No. 1 cylinder to the

top dead center.

(2) Apply engine oil to the idler shaft.

(3) Install the idler gear, aligning it with the match marks.

(4) Install the thrust plate to the idler shaft.

(5) Tighten the bolts to the specified torque.

(6) Make sure that the match marks on timing gears are

properly aligned as shown in the illustration.

Timing Gear Train

Idler Gear - Install

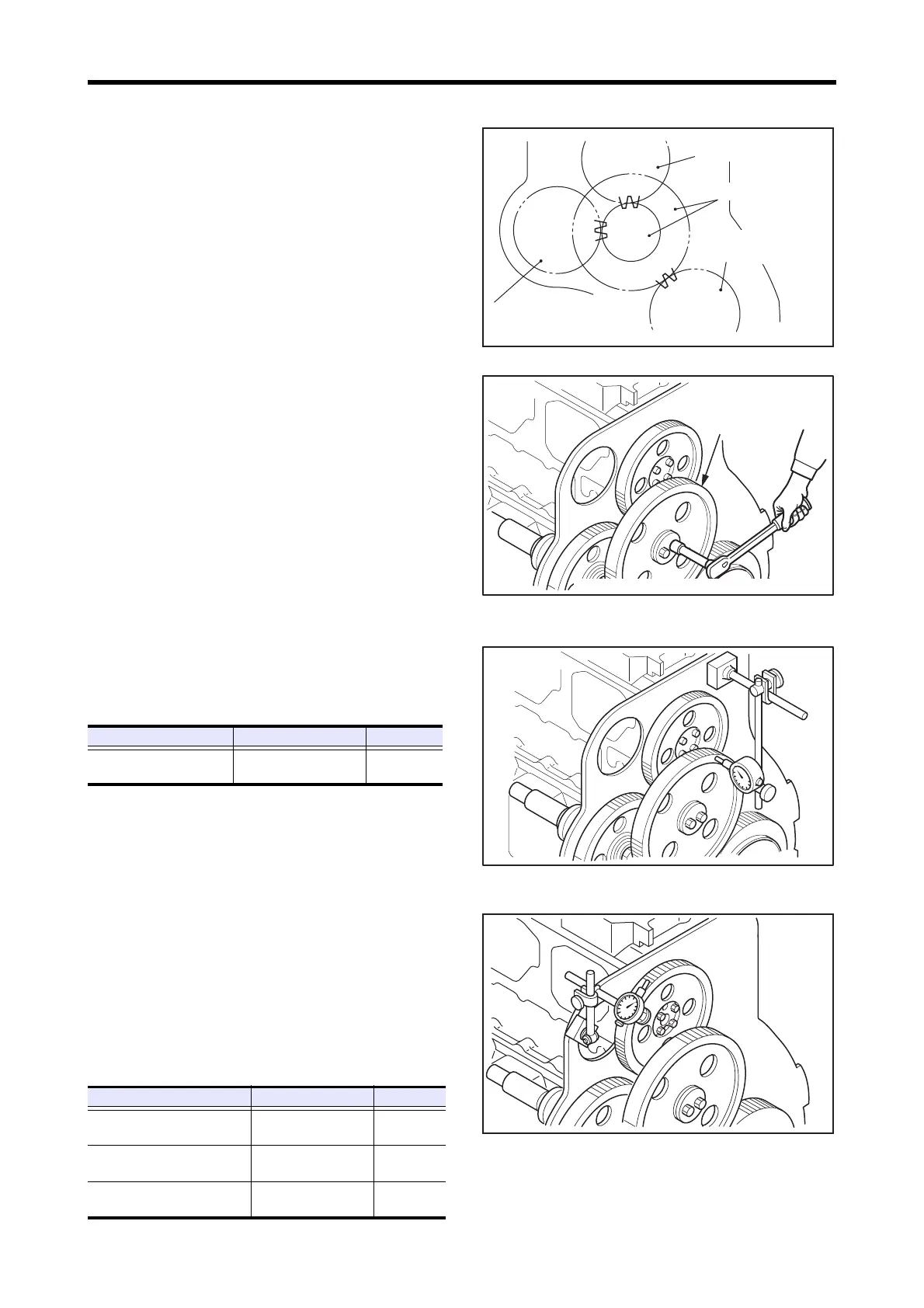

4.8 Idler Gear End Play - Measure

Measure the end play of the idler gear. If the value exceeds

the limit, find the causal parts, and replace them with new

ones.

Idler Gear End Play - Measure

4.9 Timing Gear Backlash - Measure

Measure the backlash of timing gears using either method:

measure the gear backlash with a dial gauge applying its

probe to a tooth flank on the pitch circle at a right angle to

the tooth axis, or measure the clearance between gears by

inserting thickness gauges between the engaging gear teeth.

If the value exceeds the limit, replace the gears with new

ones.

Timing Gear Backlash - Measure

Idler gear

Crankshaft gear

Fuel injection pump gear

3

3

3

2

22

1

1

1

Camshaft gear

60 ± 3.0 N·m {6.1 ± 0.31 kgf·m} [44.3 ± 2.21 lbf·ft]

Idler gear

Item Standard value Limit value

Idler gear end play

0.2 to 0.4 mm

[0.008 to 0.016 in.]

0.6 mm

[0.024 in.]

Item Standard value Limit value

Backlash between crank gear

and idler gear

0.11 to 0.28 mm

[0.0043 to 0.0110 in.]

0.50 mm

[0.0197 in.]

Backlash between idler gear

and camshaft gear

0.12 to 0.18 mm

[0.0047 to 0.0071 in.]

0.50 mm

[0.0197 in.]

Backlash between idler gear

and fuel injection pump gear

0.12 to 0.18 mm

[0.0047 to 0.0071 in.]

0.50 mm

[0.0197 in.]

Loading...

Loading...