Loading...

Loading...

Do you have a question about the MR ETOS ED and is the answer not in the manual?

Defines the intended and correct usage of the motor-drive unit.

Key safety guidelines for preventing accidents and damage.

Details on required PPE for safe operation and maintenance.

General recommendations for operating the product safely with IT security considerations.

IT security recommendations for the commissioning phase of the device.

IT security recommendations to follow during the operation of the device.

Information on how the motor-drive unit is packaged and delivered.

Explanation of how the motor-drive unit adjusts tap-changer positions.

Overview of optional function packages available for the device.

Procedure for emergency operation during switching blocking.

Instructions for accessing and using the device visualization.

Step-by-step instructions for mounting the control cabinet onto the transformer.

Detailed steps for centering the OLTC and motor-drive unit.

Description of ISM assemblies and their connection requirements.

Important notes and precautions for connecting sensors to the MR sensor bus.

Safety precautions and guidelines for connecting the motor-drive unit.

Cable recommendations for various circuits according to Maschinenfabrik Reinhausen GmbH.

Step-by-step instructions for the electrical connection of the motor-drive unit.

Preparation and commissioning steps for starting up the motor-drive unit.

Safety precautions and tests to perform on the motor-drive unit.

How to use the commissioning wizard for parameter setup.

Procedure to check the plausibility of measured values and I/O status.

Procedure to check temperature measurements and sensor wiring.

How to operate the motor-drive unit remotely.

Procedures for operating the motor-drive unit locally.

Safety warnings and instructions for operating the unit with the hand crank.

Instructions for establishing a connection to the device visualization.

How to set general device functions using parameters.

Configuring automatic logout after a period of inactivity.

Procedure for activating/deactivating service user access for diagnostics.

Configuring network interfaces for control system communication.

Activating and configuring the MQTT message protocol.

Methods for setting the device time manually or via SNTP.

Configuring the transmission of log messages via syslog protocol.

Activating and setting a screensaver to increase display service life.

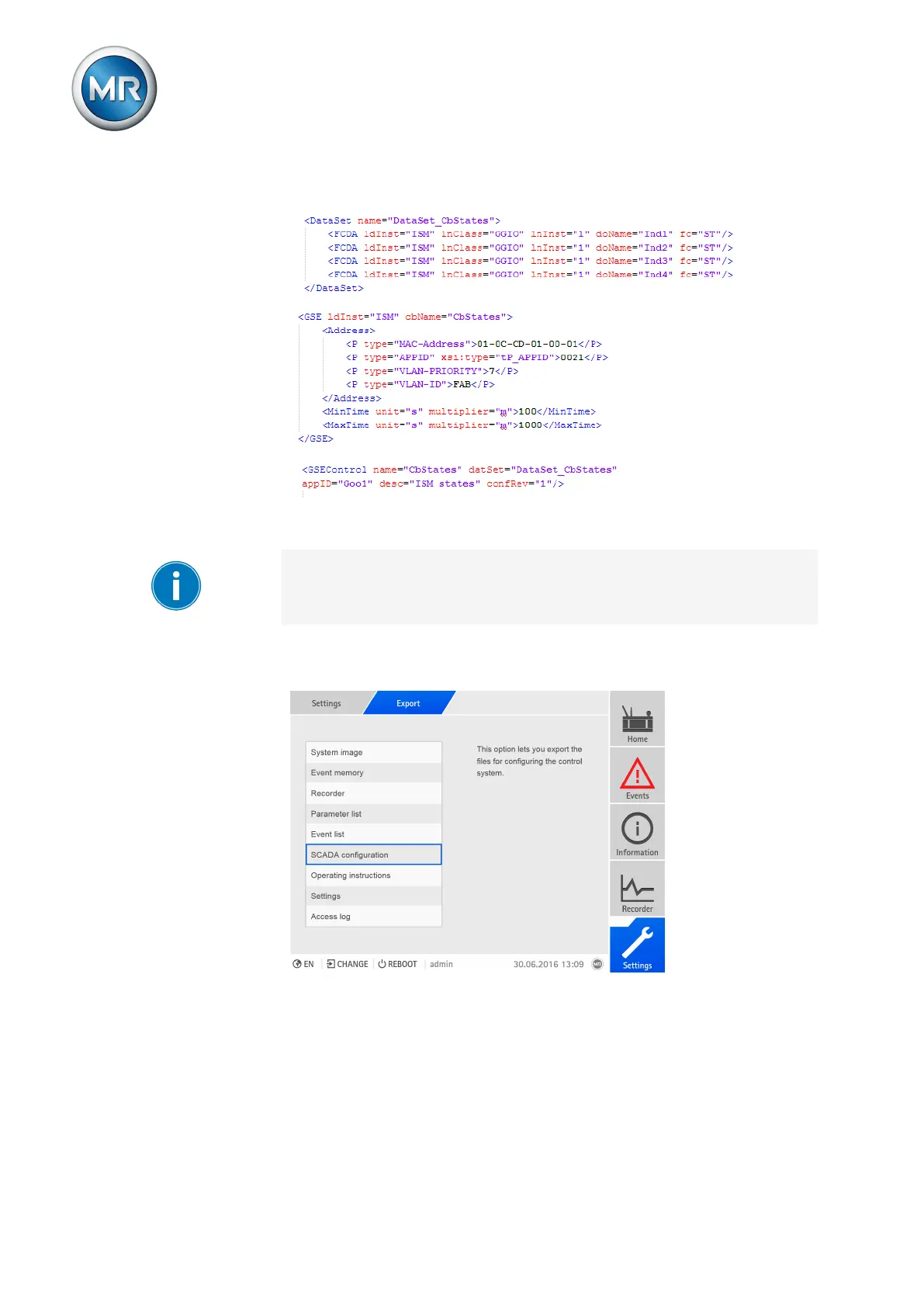

Configuring the device to connect to a control system (SCADA).

Setting parameters for the IEC 61850 control system protocol.

Setting parameters for the IEC 60870-5-101 protocol.

Setting parameters for the IEC 60870-5-103 protocol.

Setting parameters for the IEC 60870-5-104 protocol.

Setting parameters for the Modbus control system protocol.

Setting parameters for the DNP3 control system protocol.

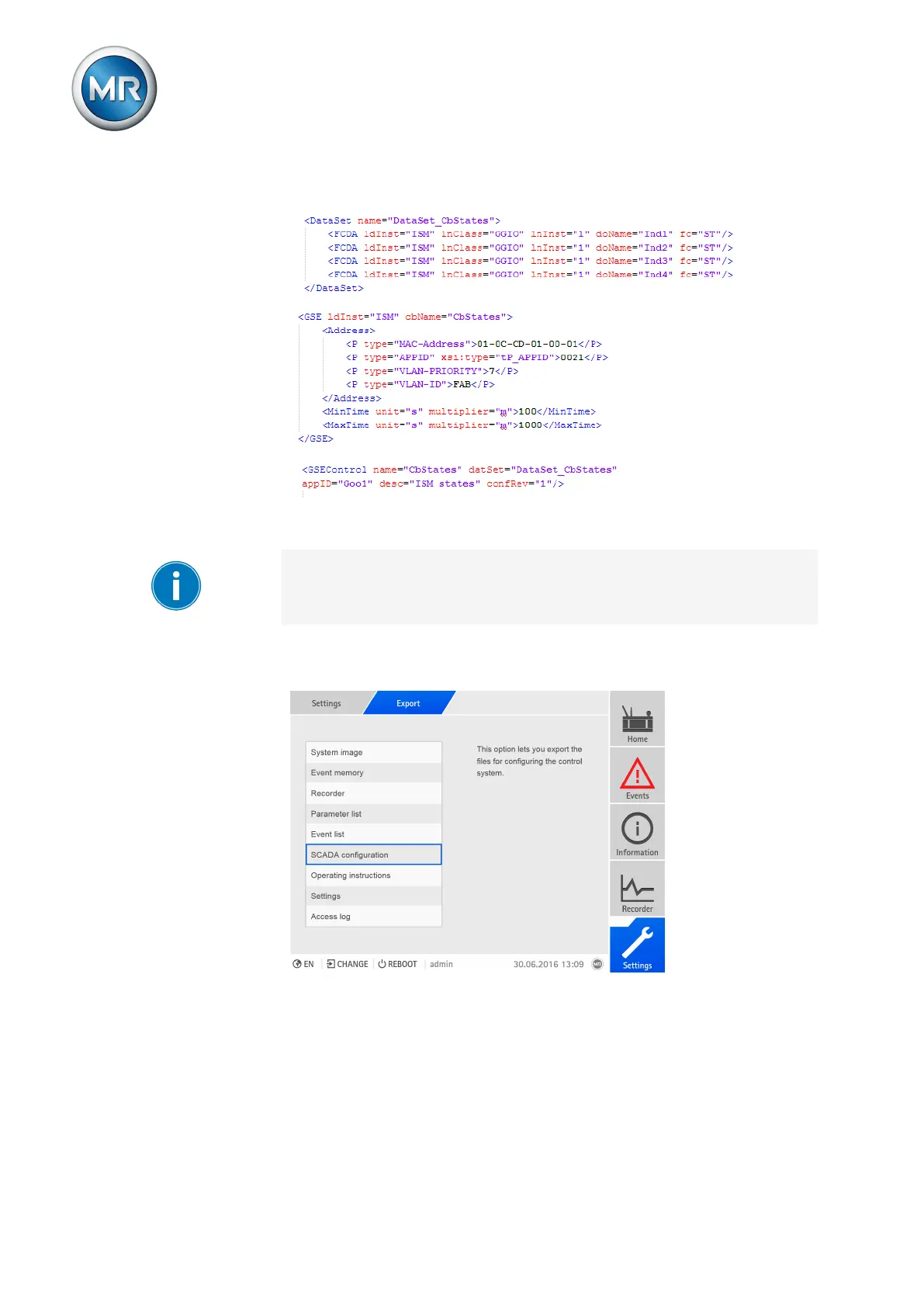

Using the GOOSE function to send or receive GOOSE messages.

Adjusting control system data points using the web visualization.

Controlling cooling system fans using frequency based on temperature and load.

Compensating for load-dependent voltage drop using R&X or Z compensation.

Setting parameters for hot-spot calculation.

General safety warnings related to fault elimination procedures.

Troubleshooting for faults where the switching operation is incomplete.

Guidelines for using the hand crank in emergency fault situations.

Troubleshooting for ISM hardware and software faults.

Safety warnings related to disassembly of energized components.

Technical data for the standard design of the motor-drive unit.

Immunity to electrostatic discharge, high-frequency fields, and impulse voltages.