Profinet

114 Rev. G Nov/2015 MI3

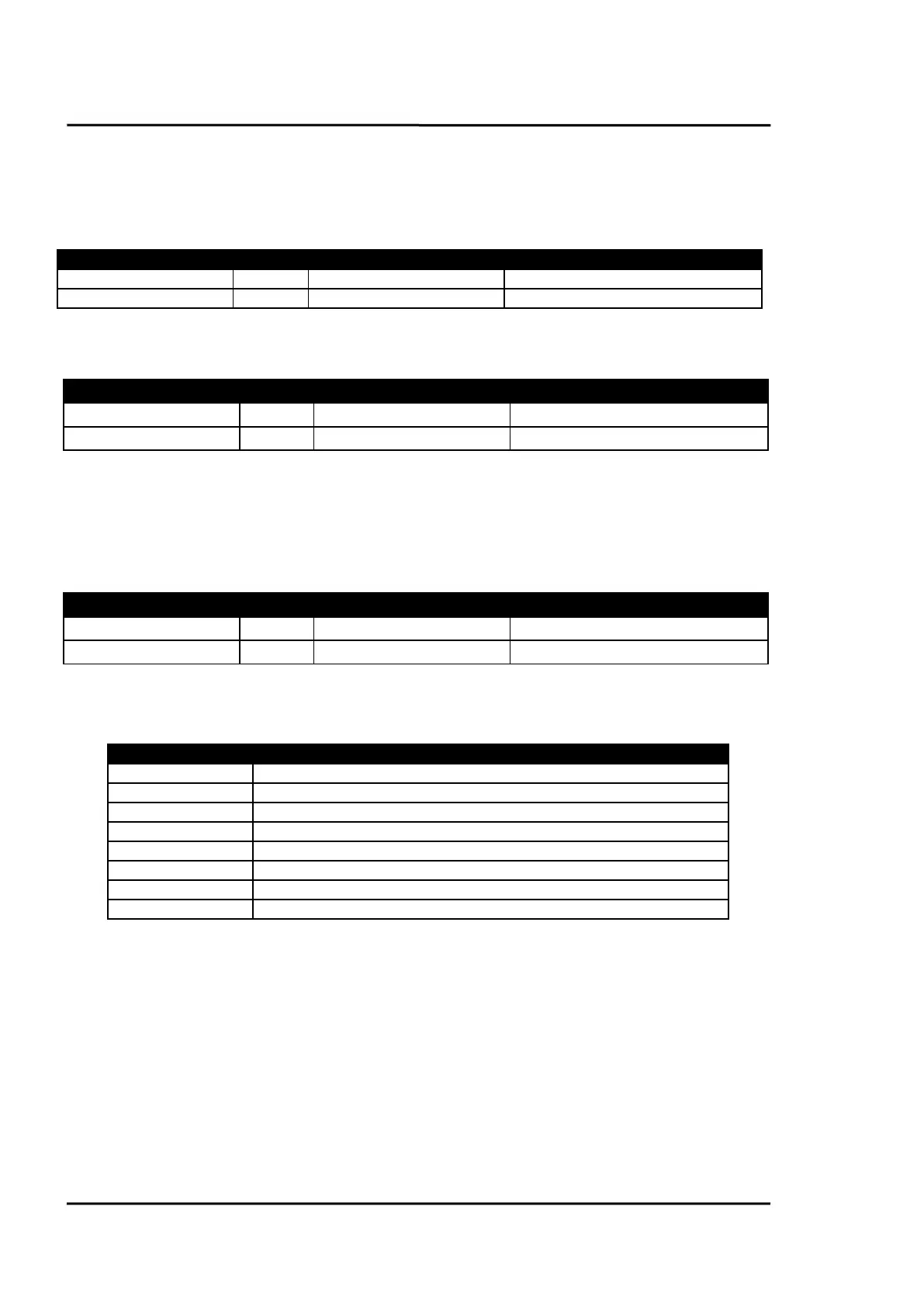

17.2.3 Input Data Structure

17.2.3.1 Input Data of Fieldbus Communicator

The input data length is 5 Byte.

Trigger state ( 0 – inactive, 1 – active)

Real (Big Endian, Motorola)

Internal temperature of the station

17.2.3.2 Input Data of Pyrometer Module

The input data length of pyrometer module is 8 Byte.

Real (Big Endian, Motorola)

Real (Big Endian, Motorola)

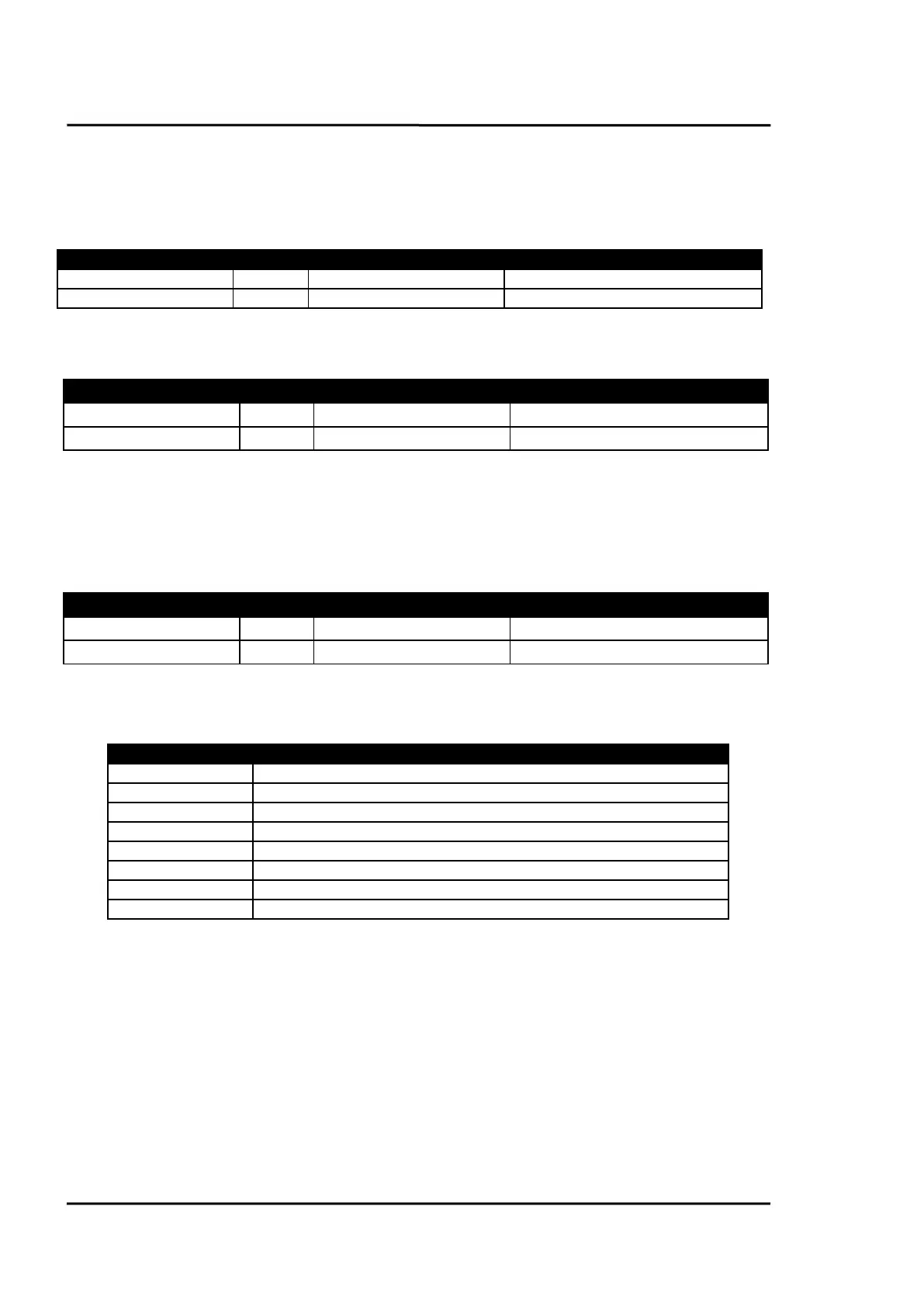

17.2.4 Output Data Structure

The pyrometer module provides output data. The output data length of pyrometer module is 3 Byte.

The output data may be used to change the initialization of the device (which was set once at start-up)

when the bus is in data exchange mode.

To do so the following structure is defined:

Byte (Big Endian, Motorola)

Integer (Big Endian, Motorola)

The <Type of parameter> gives the meaning of the following parameters (with the same format as

described in section 17.2.2.2 Parameters of the Pyrometer Module, page 113):

background temperature (for background temperature compensation)

If <Type of parameter> is set to 0 then the output data gets ignored. So it should be set to 0 as default.

17.2.5 Diagnostics

The diagnostics information of the fieldbus communicator and the pyrometer modules can be read out

anti-cyclically using standard diagnostics data sets defined in the Profinet IO specification.

Errors occurring when configuring and setting the parameters of the fieldbus communicator and the

connected pyrometer modules as well as external errors are reported by the communicator via

channel specific diagnostic.

In productive data exchange between the I/O controller and the fieldbus communicator, one byte IOPS

process data qualifiers are available for each module providing information of the validity of the

pyrometer module data (good/ bad). In the event of an error occurs during operation, the problem-

Loading...

Loading...