Loading...

Loading...

Do you have a question about the RayTek MI3 and is the answer not in the manual?

| Spectral Response | 8 to 14 µm |

|---|---|

| Response Time | 500 ms |

| Display Resolution | 0.1 °C |

| Accuracy | ±1% or 1°C (2°F), whichever is greater |

| Emissivity | Adjustable 0.10 to 1.00 |

Provides instructions for operating the MI3 Miniature Infrared Sensor.

Contact information for Raytek's worldwide and European headquarters, and service center.

Details manufacturer's warranty for product defects, exclusions, and software.

Important information for safe operation, acceptable/unacceptable uses, and parts.

Explains various safety symbols used in the manual and on the device.

Details safety measures for the Class 2 laser and electrical hazards.

Introduces the MI3 sensor series, its capabilities, and key features.

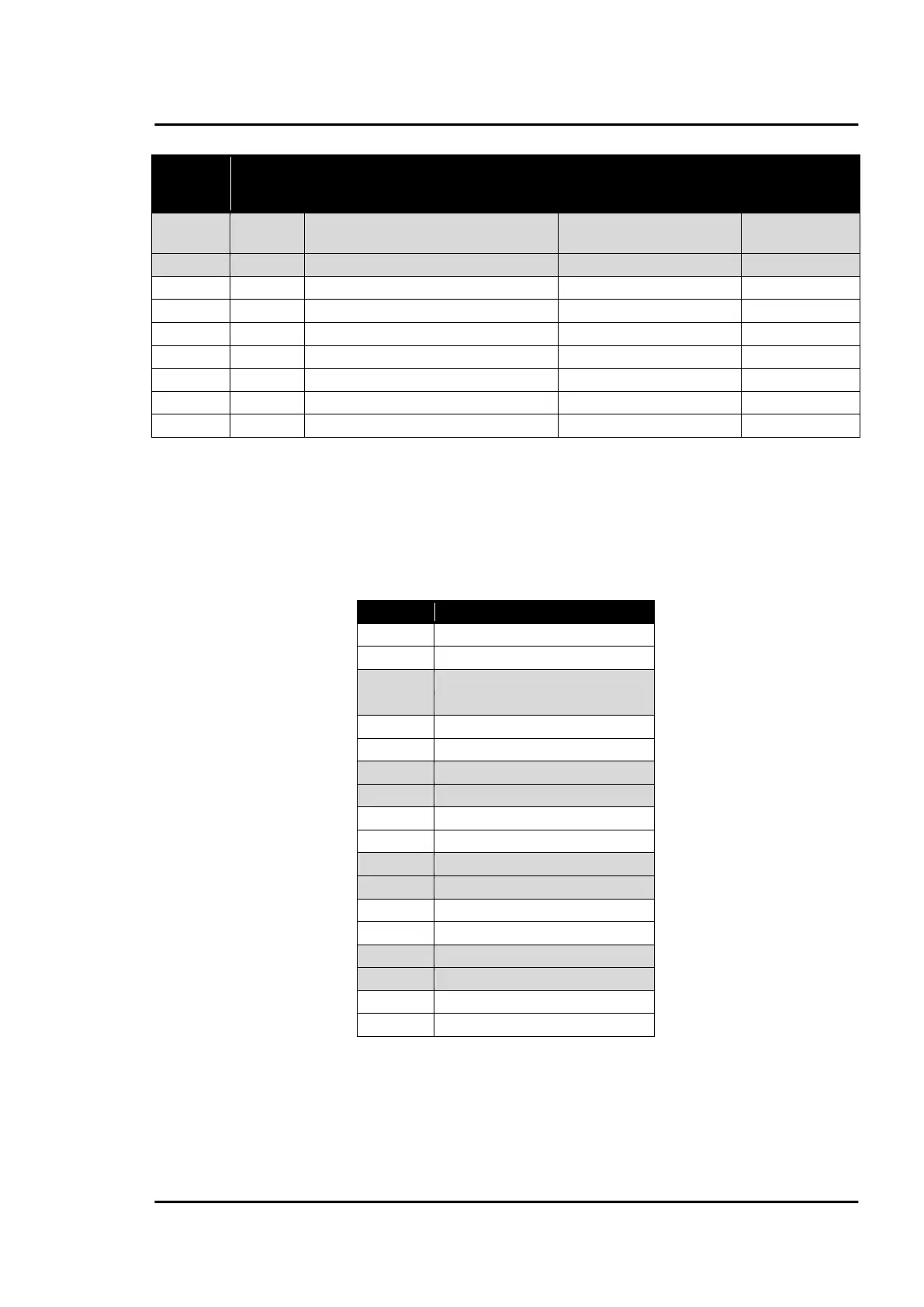

Compares the capabilities of different MI3 communication box models.

Details measurement capabilities, temperature range, and response time for sensing heads.

Lists accuracy, resolution, and loop times for Comm Boxes.

Illustrates spot sizes for different optical resolutions.

Details electrical characteristics like voltage, power, and interfaces for Comm Boxes.

Outlines environmental conditions for sensing heads and metal Comm Boxes.

Outlines environmental conditions for DIN Comm Boxes and LTH Electronics.

Provides dimensional drawings for sensing heads and metal Comm Box.

Details dimensions for DIN Comm Boxes and scope of delivery for sensing heads.

Lists items included with the Comm Box delivery.

Explains principles of infrared measurement, emissivity, and ambient conditions.

Guidance on minimizing electrical interference and proper grounding techniques.

Guides sensor placement, distance, and typical installation configurations.

Instructions for wiring the sensing head cable to the Comm Box.

Step-by-step guide for connecting the sensing head cable to a metal Comm Box.

Notes on DIN wiring and terminal connections for metal Comm Box.

Terminal wiring diagram for the DIN 3TE Comm Box.

Terminal wiring diagram for the DIN 4 TE Comm Box.

Terminal wiring for DIN 6 TE Comm Boxes for Profibus/Modbus.

Terminal wiring for DIN 6 TE Comm Boxes for Profinet/Modbus.

Terminal wiring for DIN 6 TE Comm Boxes with analog outputs.

Instructions for mounting shield wire and ferrite cores for EMI compliance.

Step-by-step guide for powering up single and multiple head systems.

Instructions for connecting the sensor to a computer via USB.

Guidance on installing and verifying the USB driver for the sensor.

Information on fieldbus connection, addressing, and RS485 network recommendations.

Overview of output setups and configuration for Analog Output OUT1 and OUT2.

Configuration for analog outputs on DIN 6TE, and alarm relay function.

Details the thermocouple output configuration and its specifications.

Explains external inputs and FTC1 for analog emissivity control.

How to use FTC inputs for digital emissivity and ambient temperature compensation.

Details methods for ambient background temperature compensation.

How to use FTC3 for trigger and hold functions.

How to use FTC3 for controlling the laser.

Overview of control panels and LCD display elements for Comm Boxes.

Table of symbols and messages displayed on the unit.

Navigation and setting of head-specific parameters like Tambient, Emissivity, Transmissivity.

Configuration options for Laser, Averaging, Hold, Trigger, Alarm, and Defaults.

Configuring the switching behavior of the internal alarm relay.

Settings for Temperature Unit, Key Enter Lock, and Display Backlight.

Displays box info and introduces post-processing techniques.

How averaging smooths the output signal and its time delay.

Captures and holds maximum (Peak) or minimum (Valley) temperature values.

Advanced peak detection with hysteresis.

Advanced valley hold with averaging, and peak hold with averaging.

Lists available options like longer cables, network interfaces, and water-cooled housing.

Guidance on preventing condensation in water-cooled systems.

Details on intrinsically safe heads and the Ex Power Supply with ATEX/IECEx certification.

Specs for Ex Power Supply and basic installation diagram.

Illustration of external wiring and instructions for mains supply connection.

Procedures for voltage selection, grounding, and AC mains connection.

Details on fixed voltage Ex Power Supply variants and their IECEx certification.

Lists general accessories and the Multi-Channel Box.

Dimensional drawings and wiring diagram for the multi-channel box.

Guidance on correctly mounting cable shields for EMI compliance.

Details the USB/RS485 adapter and its wiring.

Lists accessories specific to LT and G5 sensing heads.

Dimensions of the adjustable mounting bracket.

Dimensions for fixed bracket and description of air purge jacket.

Instructions for mounting air purge jacket and details on the air cooling system.

Diagram illustrating the air cooling system setup and connections.

Chart showing ambient temperature limits based on air flow and hose length.

Lists and identifies the parts of the air cooling system.

Details on right angle mirrors, dimensions, and installation.

Information on protective windows and close focus lens.

Diagrams of head with lens and spot size charts.

Lists accessories specific to 1M and 2M sensing heads.

Dimensions for the fixed mounting bracket for 1M/2M heads.

Dimensions for the adjustable mounting bracket for 1M/2M heads.

Details on isolation kit and air purge collar for 1M/2M heads.

Usage and installation of the right angle mirror for 1M/2M heads.

Information on protective windows for 1M/2M heads.

Common issues, causes, solutions, and fail-safe system explanation.

Lists error codes for various outputs and instructions for cleaning the sensor lens.

Procedure for exchanging a sensing head and parameter management.

Overview of software features, PC requirements, driver installation, and launch.

RS485 specifications, wiring diagrams for metal Comm Box, and ASCII programming reference.

Explains Profibus DP-V0 protocol and wiring for metal Comm Box.

Terminal assignments for Profibus DIN Comm Box and pin assignments for connectors.

Terminal assignments for Profibus DIN 6TE Comm Box.

Details on Profibus parameter data, format, and range.

Structure and description of Profibus input data.

Structure of output data and explanation of diagnose data.

Details on diagnose data bytes and error bit meanings.

Example of diagnose data showing errors like cable breaks.

Explains Modbus protocol and wiring for metal Comm Box.

Terminal assignments for Modbus DIN 6TE Comm Box.

Details on Modbus functions and box parameters.

Continued table of Modbus box parameters and their settings.

Table of Modbus head parameters and their settings.

Continued table of Modbus head parameters and their settings.

Details on Ethernet connectivity, protocols, and wiring for Comm Boxes.

Information on IP addressing for MI3 and network configuration.

Steps to configure the PC's network adapter for communication.

Guide to setting IP address, subnet mask, and gateway.

Details on the http server and data logging function.

How to start, stop, and retrieve logged data via the http server.

Explains Profinet protocol, refers to Ethernet wiring, and details status LEDs.

Overview of Profinet programming, I/O configuration, GSD file, and parameter setting.

Parameters for configuring the fieldbus communicator.

Exemplary view of Fieldbus Communicator parameters in STEP7.

Parameters for configuring individual pyrometer modules.

Structures of input/output data and how to read diagnostics.

Explains how diagnostic information is communicated via status indicators.

Explains ASCII protocols, transfer modes, and command structure.

How to set parameters, response formats, and addressing methods.

Examples, device info retrieval, and setup commands.

How to set emissivity/alarms and configure post-processing modes.

Commands for dynamic data, device control, output scaling, and alarm output.

Commands for factory defaults, lock mode, FTC3 settings, and ambient compensation.

Summary table of ASCII commands.

Detailed table of ASCII commands, formats, and values.

Continued table of ASCII commands, formats, and values.

Continued table of ASCII commands, formats, and values.

Continued table of ASCII commands, formats, and values.

Continued table of ASCII commands, formats, and values.

ASCII commands specific to Ethernet and Profinet.

Methods for determining the emissivity of target objects.

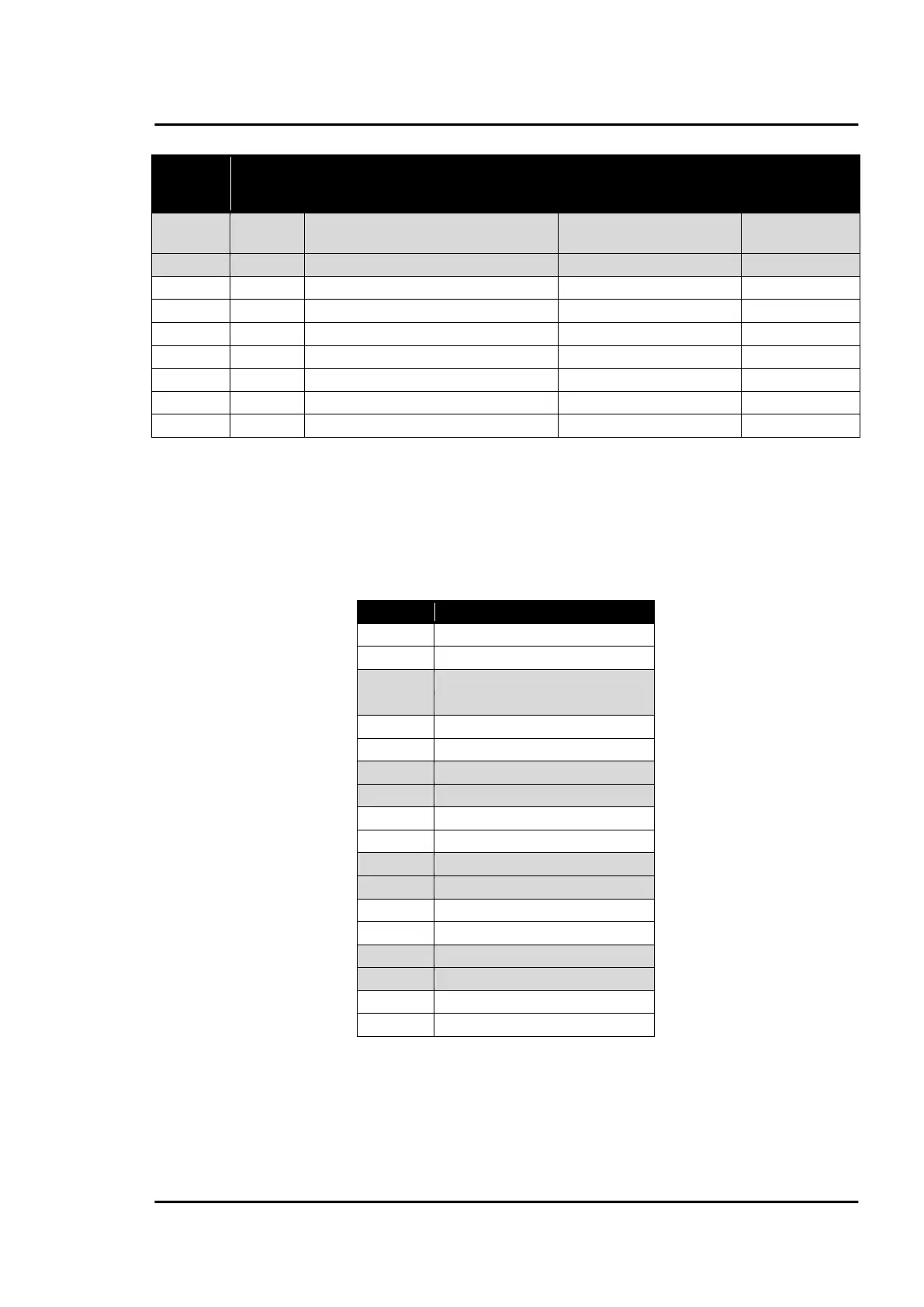

Reference table of emissivity values for various metals.

Continued table of emissivity values for metals.

Table of emissivity values for various non-metals.

ATEX certificate details for sensing heads.

Parameters and test reports related to ATEX certification.

Information on additional manufacturing locations for ATEX certification.

ATEX certificate for the Ex Power Supply.

Details on subject, type, and ratings for Ex Power Supply ATEX certification.

Confirmation of translation correctness for the ATEX certificate.

IECEx certificate details for sensing heads.

Standards relevant to the IECEx certification.

Details on the equipment covered by the IECEx certificate.

Electrical ratings and ambient temperature ranges from the IECEx certificate.

IECEx certificate for the Ex Power Supply.

Standards relevant to the Ex Power Supply IECEx certification.

Details on equipment covered by the Ex Power Supply IECEx certificate.

Ratings and electrical data from the Ex Power Supply IECEx certificate.

General notes section.