53 / 100

Siemens Commissioning Guide CM1G5192en

Building Technologies 8 Additional functions 29.07.2010

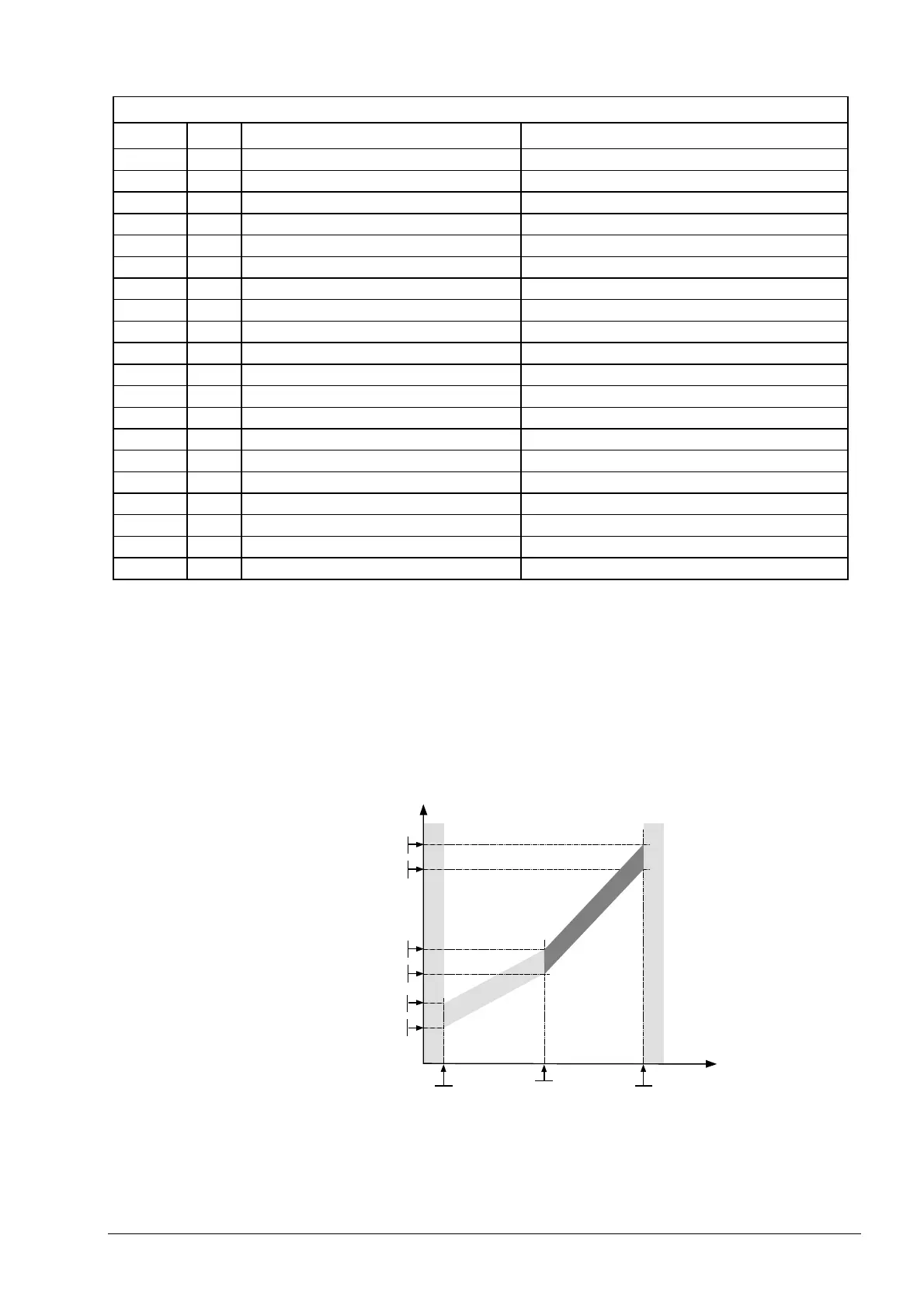

7.8.1 Parameter changes

Start with quick commissioning according to application 1

Par. no. Value Parameter function Function selection

P0501(0) 4 Type of sensor Set input scale to range of QBE620 – P25

P0701(0) 16 Function of digital input 1 in “Auto” mode Set DIN 1 for fixed freq SP + ON

P0756(0) 0 Analog input Unipolar voltage input (DC 0…10 V)

P1080 5 Motor minimum frequency Minimum frequency

P1210 3 Restart after fault / mains break Auto restart after mains fail

P2200 1 Enable PID controller Enable PID loop

P2201 60 Fixed PID setpoint Fixed setpoint as a percentage of sensor range

P2253 2224 PID setpoint PID setpoint source

P2264 755.0 PID feedback Sets PID feedback source to AIN-1

P2274 0 PID derivative action time Derivative action time

P2280 1.5 PID proportional band Proportional band

P2285 20 PID integral action time Integral action time

P2306 0 PID acting direction Direct acting loop

P2390 20 Hibernation frequency Hibernation setpoint [%]

P2391 60 Hibernation timer Hibernation timer in seconds

P2392 -5 Restart PID controller deviation Restart – PID error in %

r2262 Filtered PID setpoint Display actual setpoint in C

r2272 PID scaled feedback Display actual condenser pressure

r2273 PID error Display actual PID error in %

r2294 PID output Display actual VSD output in %

8 Additional functions

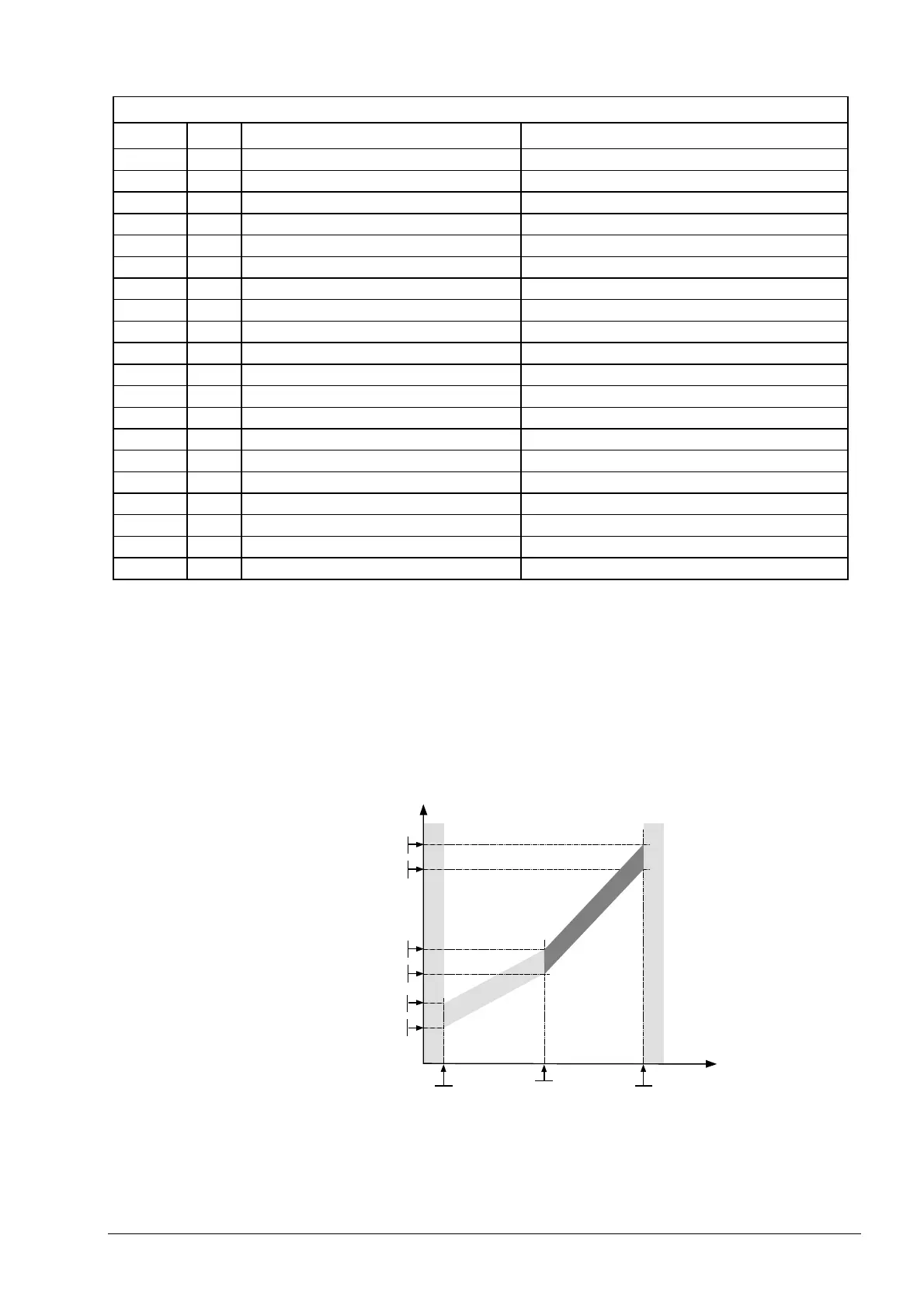

8.1 Belt failure detection without sensor

Carry out quick commissioning and modify the parameters for normal operation, then proceed as follows:

Frequency /

torque curve

Torque [Nm]

Frequency [Hz]

Threshold frequency 1 Threshold frequency 3

Threshold frequency 2

P2182 P2184

P2183

P2189

Upper torque threshold 3

P2190 unterer

Lower torque threshold 3

P2187

Upper torque threshold 2

P2188

Lower torque threshold 2

P2185

Upper torque threshold 1

P2186

Lower torque threshold 1

5192D01en

Loading...

Loading...