54 / 100

Siemens Commissioning Guide CM1G5192en

Building Technologies 8 Additional functions 29.07.2010

8.1.1 Parameter setting

Start with quick commissioning according to application 1

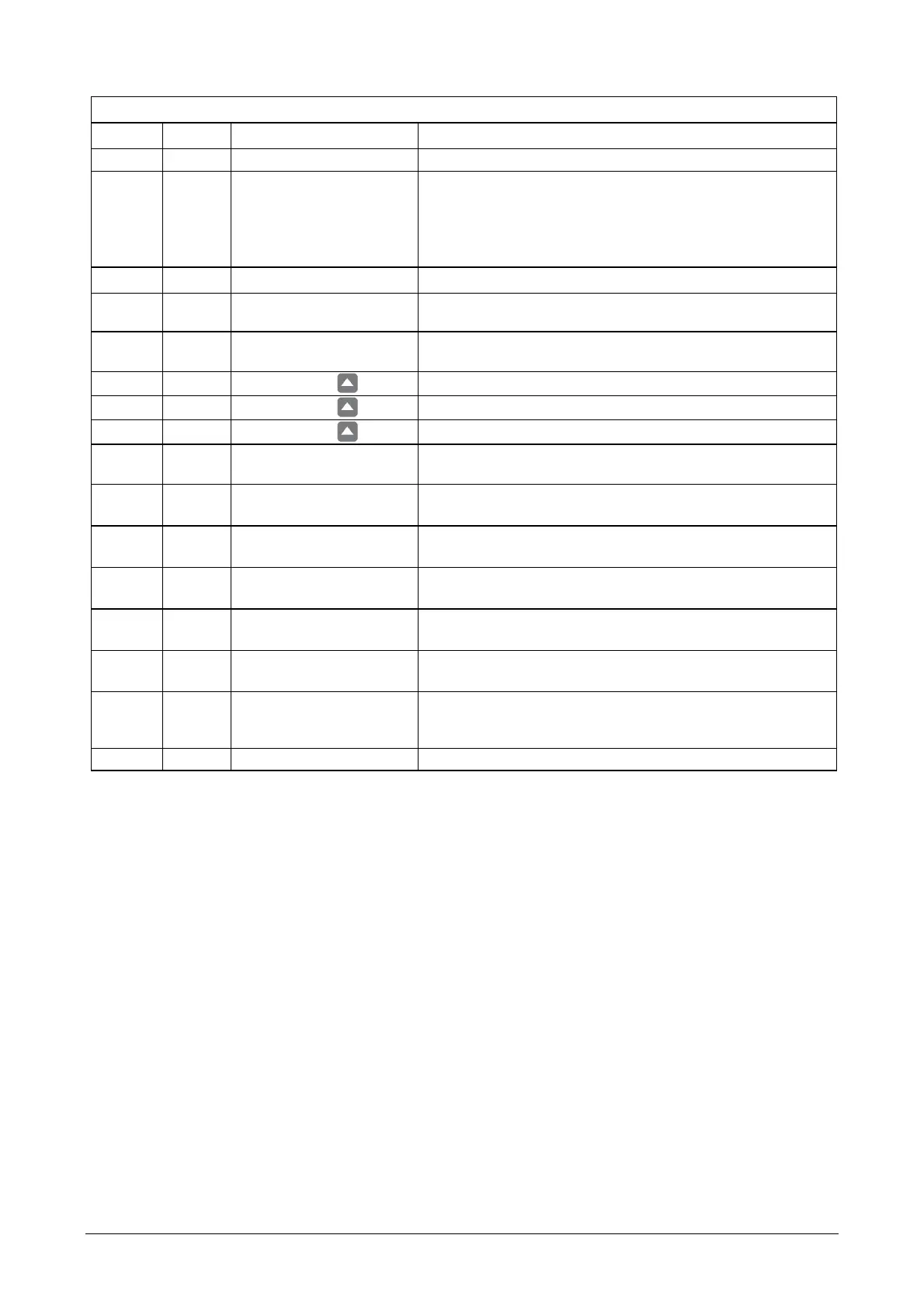

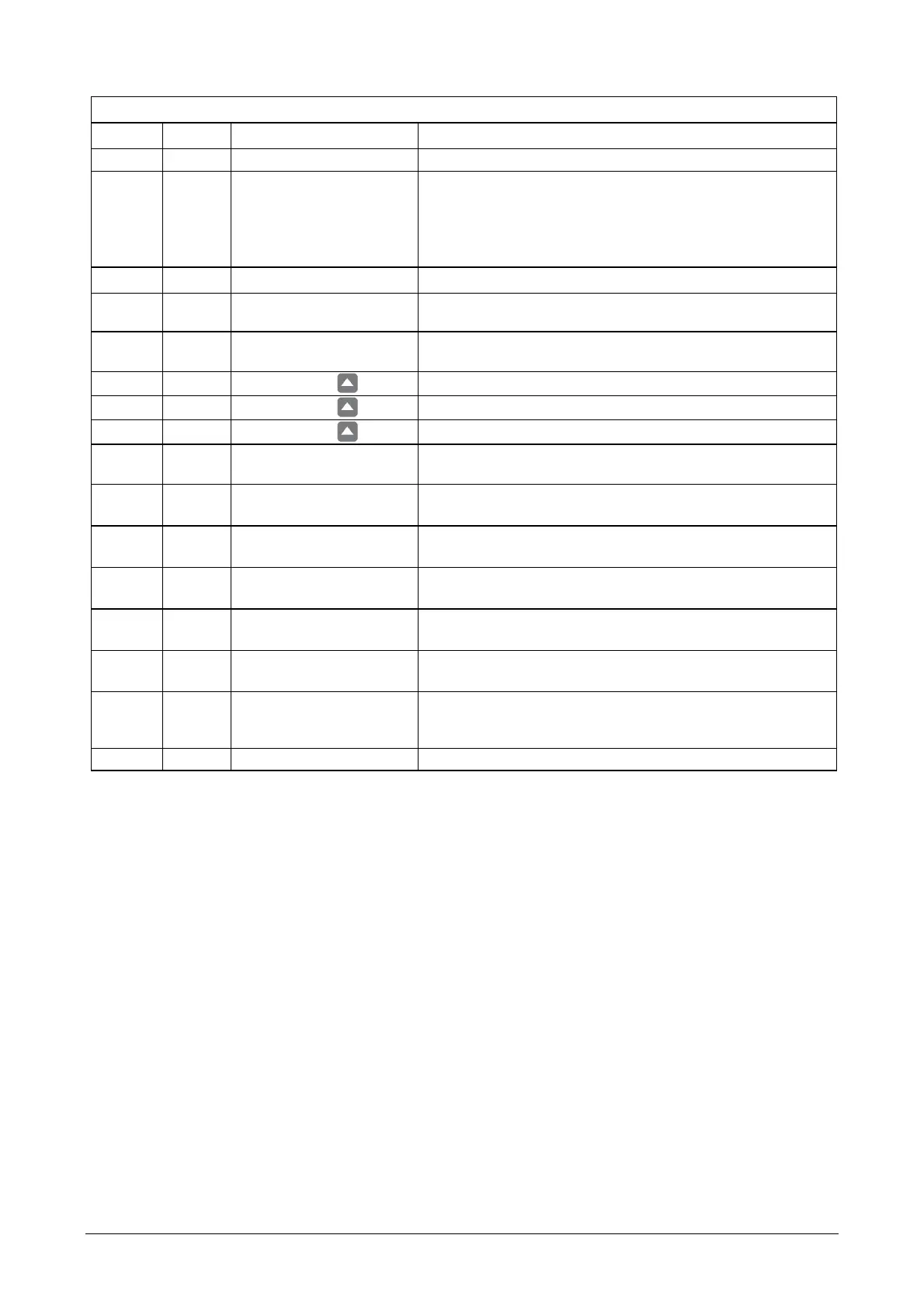

Par. no. Value Parameter function Function selection

P0003 3 User access level Expert access

P2182 14 Hz Belt threshold 1

Sets a frequency threshold F1 for comparing actual torque to

torque the envelope for belt failure detection. The frequency

torque envelope is defined by 9 parameters – 3 are frequency

parameters (P2182 - P2184) and the other 6 define the low

and high torque limits (P2185 - P2190) for each frequency

Par. no. Value Parameter function Function selection

P2183 30 Hz Belt threshold 2

Sets a threshold F2 for comparing actual torque to torque

within the envelope for belt failure detection

P2184 51 Hz Belt threshold 3

Sets a threshold F3 for comparing actual torque to torque

within the envelope for belt failure detection

r0031 15 Hz

Adjust with the

button

Read the torque at 15 Hz and note it here: ......................

r0031 30 Hz

Adjust with the

button

Read the torque at 30 Hz and note it here: ......................

r0031 50 Hz

Adjust with the

button

Read the torque at 45 Hz and note it here: ......................

P2185 ≥+ 25%

Upper torque threshold

frequency 1

Add 25% to the torque reading taken at 15 Hz

P2186 ≥- 25% Lower torque threshold

frequency 1

Subtract 25% of the torque reading taken at 15 Hz

P2187 ≥+ 25% Upper torque threshold

frequency 2

Add 25% to the torque reading taken at 30 Hz

P2188 ≥- 25% Lower torque threshold

frequency 2

Subtract 25% of the torque reading taken at 30 Hz

P2189 ≥+ 25% Upper torque threshold

frequency 3

Add 25% to the torque reading taken at 50 Hz

P2190 ≥- 25% Lower torque threshold

frequency 3

Subtract 25% of the torque reading taken at 50 Hz

P2192

Suggest

30 s

Time delay for belt failure

Defines a delay before warning / trip becomes active. It is

used to eliminate events caused by transient conditions. It is

used for both methods of fault detection

P2181 6 Belt failure detection mode Trip on high / low torque / speed

Loading...

Loading...