2.5 Use in hazardous areas

2.5.1 Internal explosion protection

Internal explosion protection refers to the sample gas path (containment system "CS") in the

analyzer and to the explosion protection of the process gas. A dierentiation must be made

between the following cases:

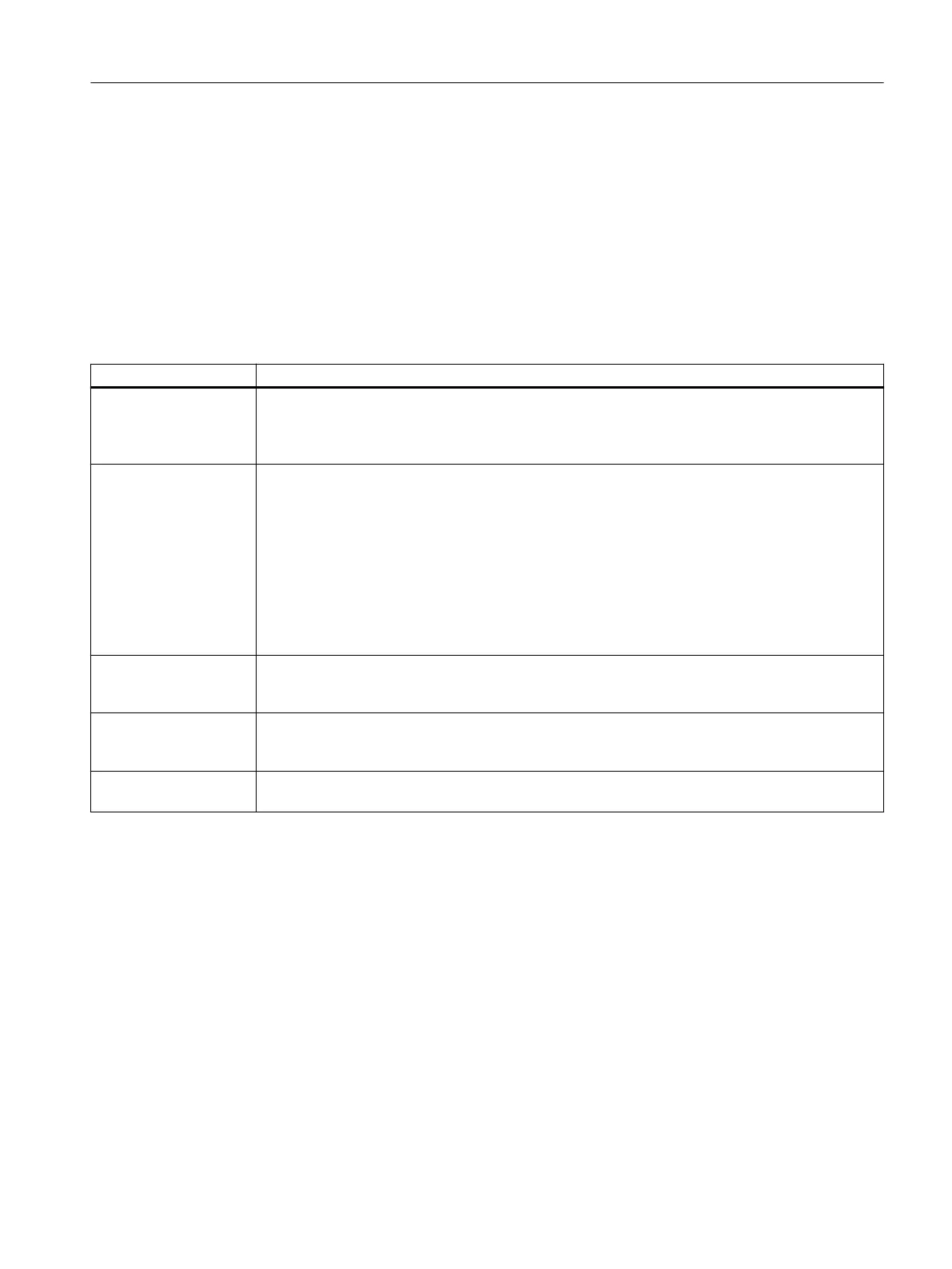

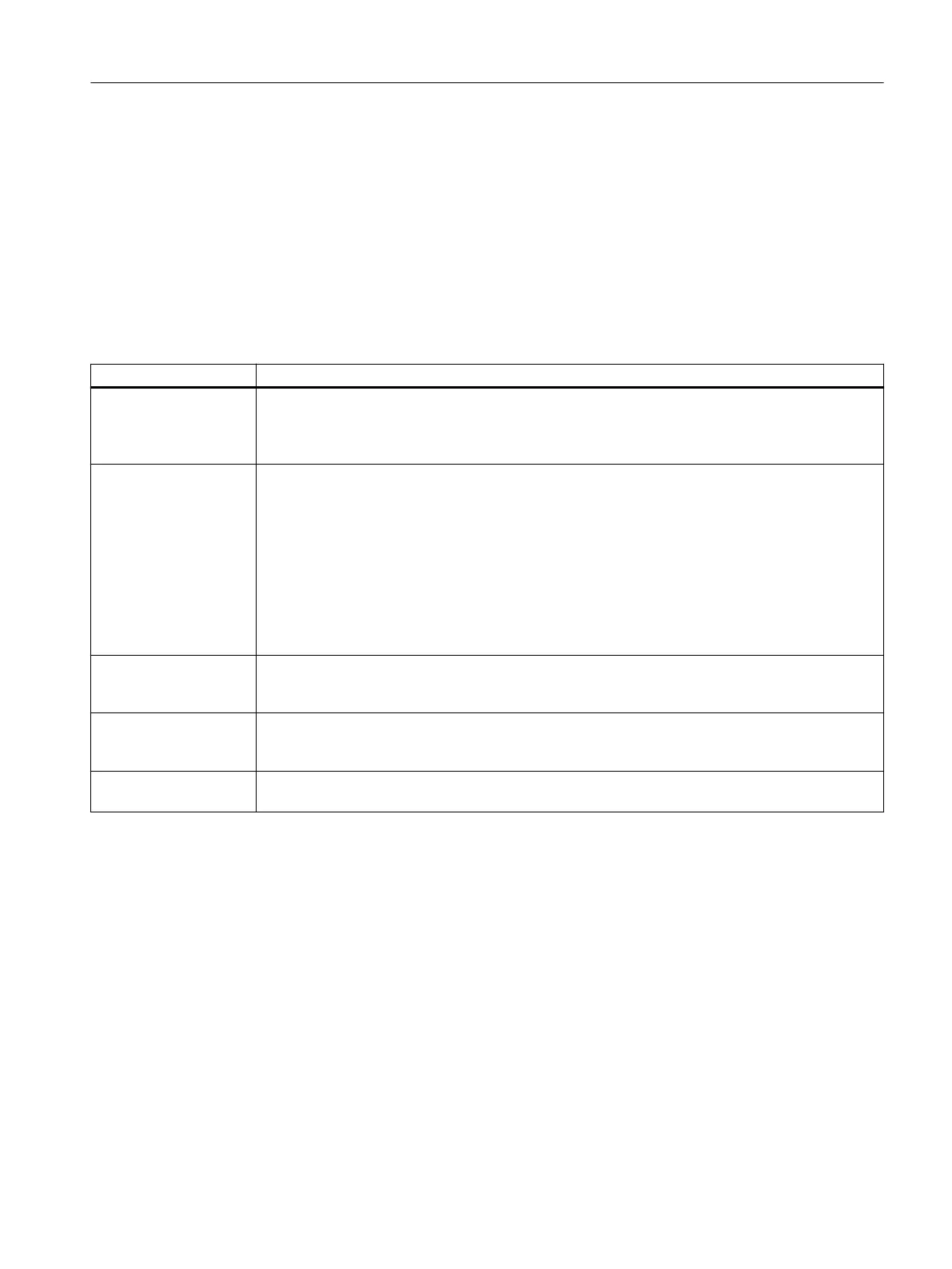

Table 2-1 Internal explosion protection: Dierentiation of cases

Sample gas Measures

Non-ammable gas mix‐

tures and gas mixtures

below 25% of the lower

ammable level (LFL)

If you have ensured that the sample gas in the CS does not become ammable, ame arrestors are

dispensable.

Occasionally explosive

gas mixtures below up‐

per ammable limit

(UFL)

The introduction of an occasionally explosive gas mixture into the wall-mounted device is permis‐

sible only with the explosion protection type Ex px/py, under NFPA 496 for North America amma‐

ble gases may be introduced using APU described in Ex pz safety equipment (Page115). We rec‐

ommend an automatic purging unit in accordance with Ex px.

When introducing a ammable or occasionally explosive gas mixture in OXYMAT 7 into the wall-

mounted device, each inlet/outlet for sample gas and reference gas must be equipped with a ame

arrestor. The installed ame arrestors have to full the safety-specic requirements of this amma‐

ble gas mixture.

Introducing a ammable gas mixture below upper ammable limit in OXYMAT 7 into the rack-

mounted device is not permissible.

Gas mixtures which are

frequently or perma‐

nently explosive

Do not introduce any frequently or permanently explosive gas mixtures!

Gas mixtures above the

upper ammability level

(UFL)

A case-by-case assessment is required for these ammable gas mixtures.

Flammable gas mixtures

with OXYMAT 7

Flame arrestor is needed, make sure the reference gas pressure is always 2000 hPa (± 150 hPa)

above sample gas pressure.

2.5.2 External explosion protection

2.5.2.1 Overview

The external explosion protection serves to prevent penetration of ammable gas mixtures (gas

vapors) into the enclosure or ignition on the surfaces.

OXYMAT 7: When conducting ammable or non-ammable sample gases into the hazardous

area, both the sample gas inlet and outlet must be provided with a ame arrestor.

The maximum permissible sample gas pressure in the analyzer depends on the type of

connected gas. Make sure that no higher sample gas pressures occur than specied in the

technical data of the respective device version. The exact specications of the sample gas

inlet conditions can be found in the section "Technical data (Page87)".

Safety notes

2.5Use in hazardous areas

SIPROCESS GA700 rack and wall mounted devices

Compact Operating Instructions, 06/2023, A5E35134047-AB 19

Loading...

Loading...