Note

Correct fastening of the cable glands

Fasten the cable glands as follows:

• M16 x 1.5 clamping range 5 to 10 mm (0.2" .. 0.39") made of plastic, counter nut and cap nut

(clamp cables or plugs) with a torque of 3.0 Nm.

• M20 x 1.5 clamping range 10 to 14 mm (0.4" .. 0.55") made of plastic, counter nut and cap

nut with a torque of 4.5 Nm.

• M16 x 1.5 clamping range 6 to 10 mm (0.2" .. 0.39") made of metal, counter nut and cap nut

with a torque of 6.5 Nm.

• M20 x 1.5 clamping range 10 to 14 mm (0.4" .. 0.55") made of metal, counter nut and cap

nut with a torque of 9.0 Nm.

To ensure tightness of cable glands, use cable diameters of:

• 5 mm .. 10 mm (0.2" .. 0.39") for cable glands M16x1.5

• 10 mm .. 14 mm (0.4" .. 0.55") for cable glands M20x1.5

7.1.3 OXYMAT 7

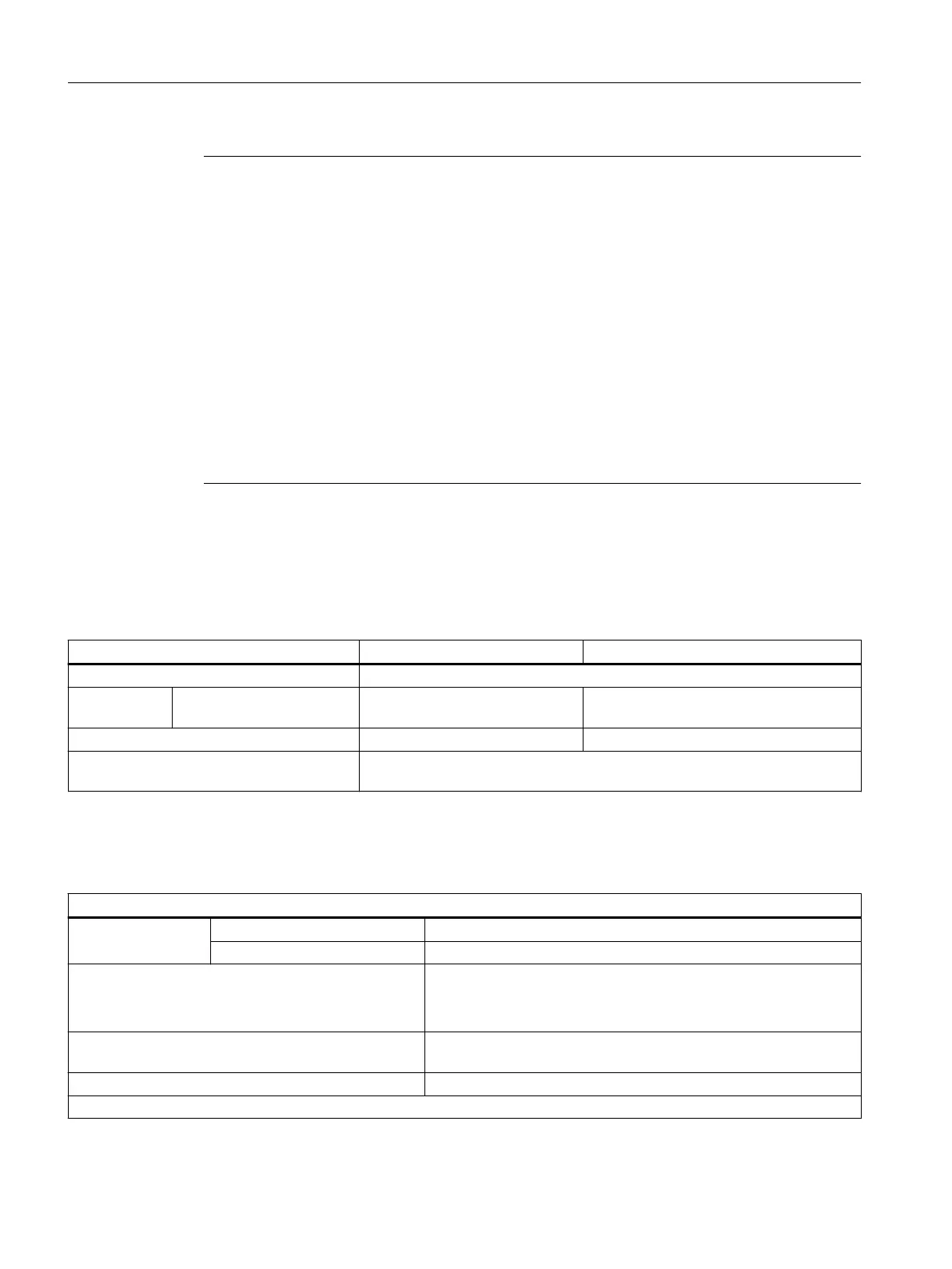

Table 7-10 OXYMAT 7: General technical data

General OXYMAT 7 OXYMAT 7 high-temperature

1)

Information on the smallest span See module nameplate or parameter sheet

Max. power

consumption

Warm-up phase ≤60W ≤120W

Weight (only module) < 5.5kg < 7.5kg

Max. EMC error during operation with one

and/or two OXYMAT7 / ULTRAMAT7 units

1.0% in accordance with EN61326-1

1)

The high-temperature version of the analyzer module is not intended for installation in the rack unit.

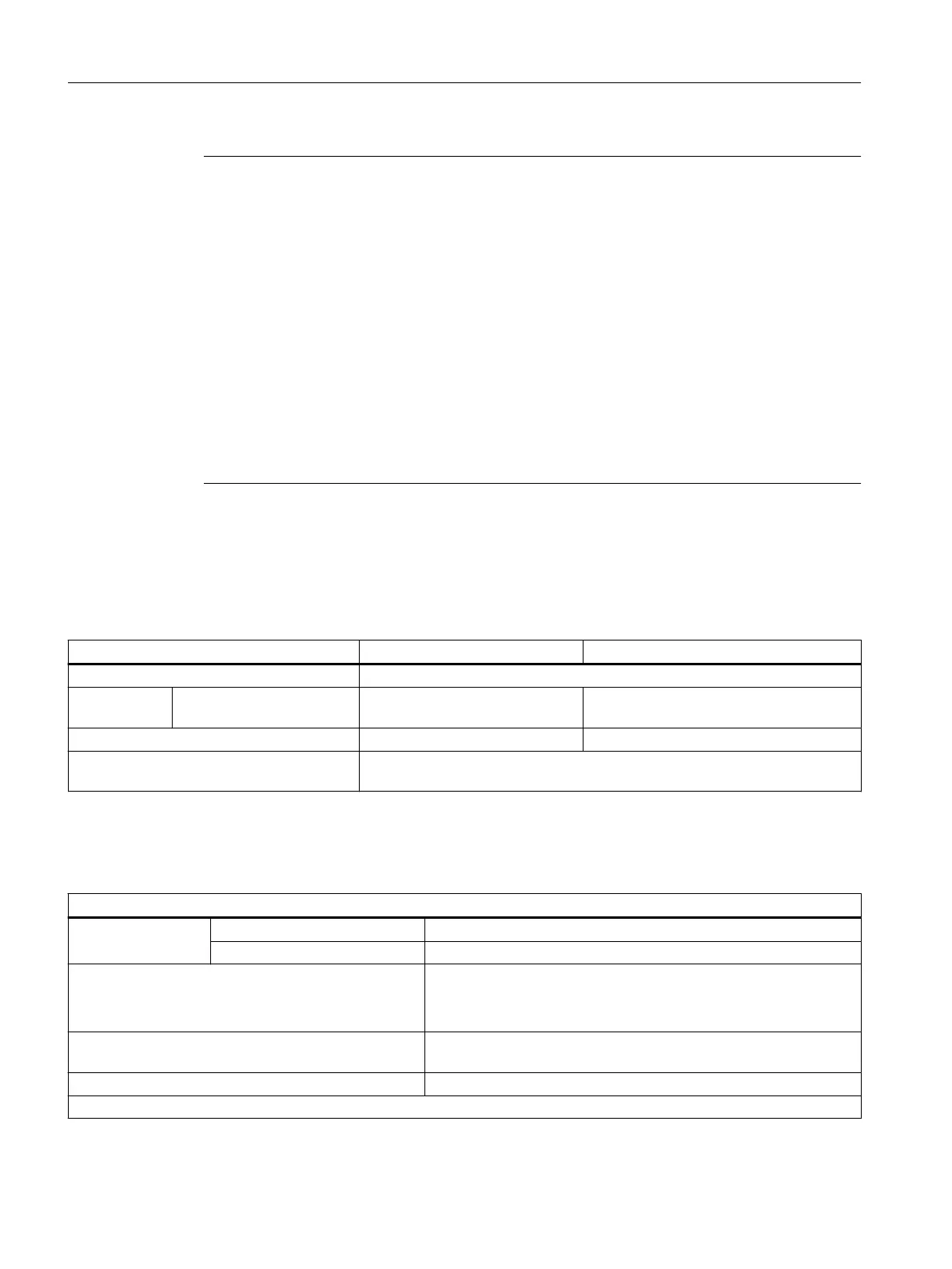

Table 7-11 OXYMAT 7: Gas inlet conditions

Gas inlet conditions

Sample gas pressure with internal pressure sensor -500 ... +1 500 hPa

with external pressure sensor -500 ... +2 000 hPa

Reference gas pressure

2000 to 4000 hPa above the sample gas pressure

1)

Max. permissible: 5000 hPa (abs.)

Only nitrogen is allowed with ammable gas as sample gas

Pressure loss between sample gas inlet and sample gas

outlet

<100hPa at 1l/min

Permissible sample gas ow range 18 to 60 l/h (0.3 to 1 l/min)

Sample gas temperature and humidity.

Technical data

7.1General technical specications

SIPROCESS GA700 rack and wall mounted devices

92 Compact Operating Instructions, 06/2023, A5E35134047-AB

Loading...

Loading...