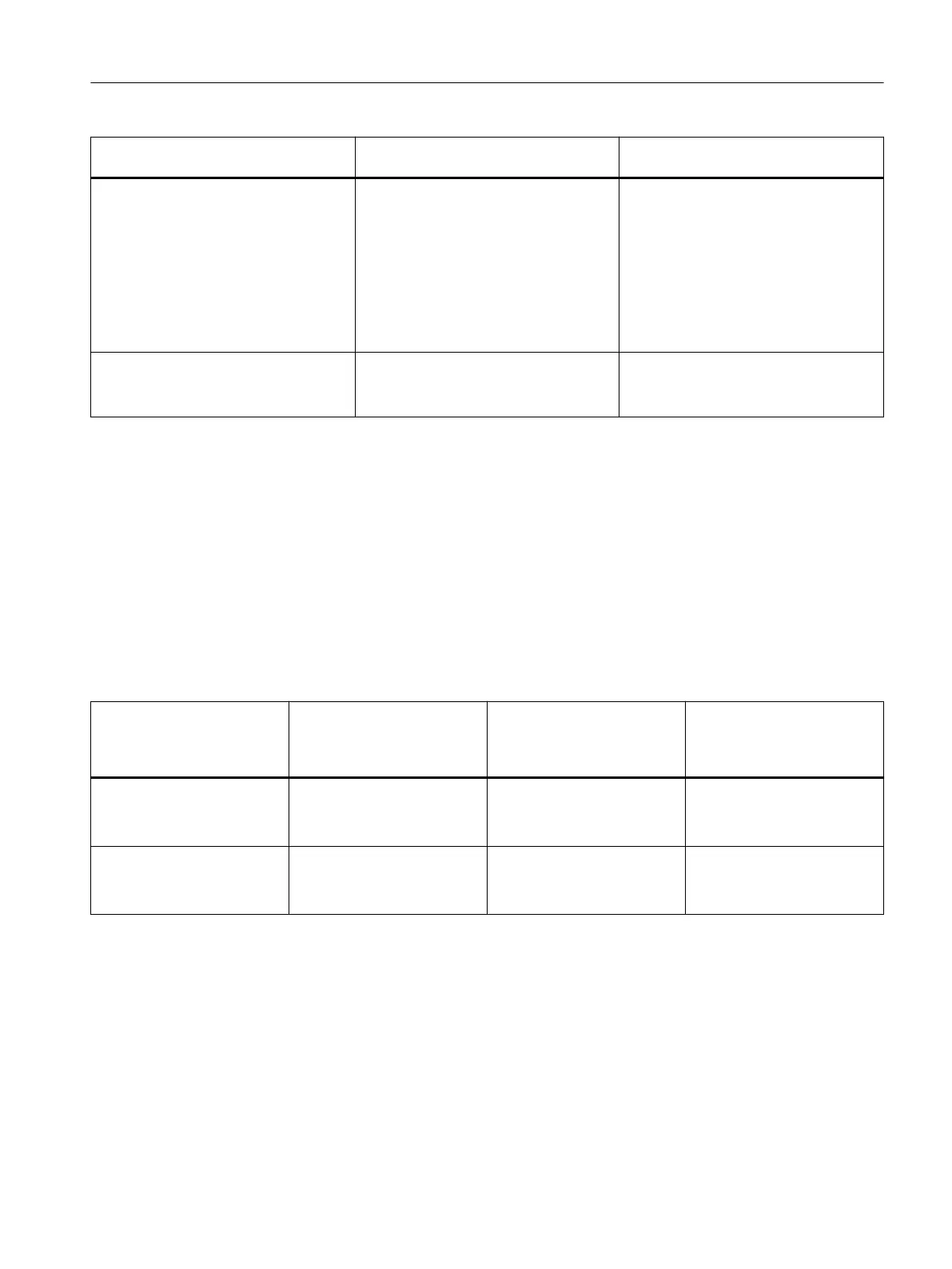

Place of installation / zone Sample gas non-ammable below the

lower explosive limit LEL (25% of LEL)

Sample gas is ammable and/or is oc‐

casionally above the LEL (25% of LEL)

Flame arrestor Not required For OXYMAT 7 and CALOMAT 7: Flame

arrestor recommended for sample gas

inlet and outlet;

For OXYMAT 7 monitoring of the refer‐

ence gas or ame arrestors in the refer‐

ence gas path

• For ULTRAMAT 7, the ame arrestors

can be omitted when using a techni‐

cally unmodied analyzer module

Monitoring Not required

• Enclosure purging monitored

2)

Regular leak test as described in the man‐

ual

1) The above-mentioned purging monitoring in py mode is permissible according to the certicate, but is explicitly not

recommended by SIEMENS. As a manufacturer,

we generally recommend the use of a purge monitor in px operation. The py operation requires immediate intervention by the

operator in the event of

failure or insucient purging, since the Ex p system only provides an alarm and no automatic shutdown.

2) For the measurement of ammable gases, a px monitoring system (option E72) is recommended, since with py purge

monitoring it must be ensured that

remedial action is taken immediately in the event of malfunction.

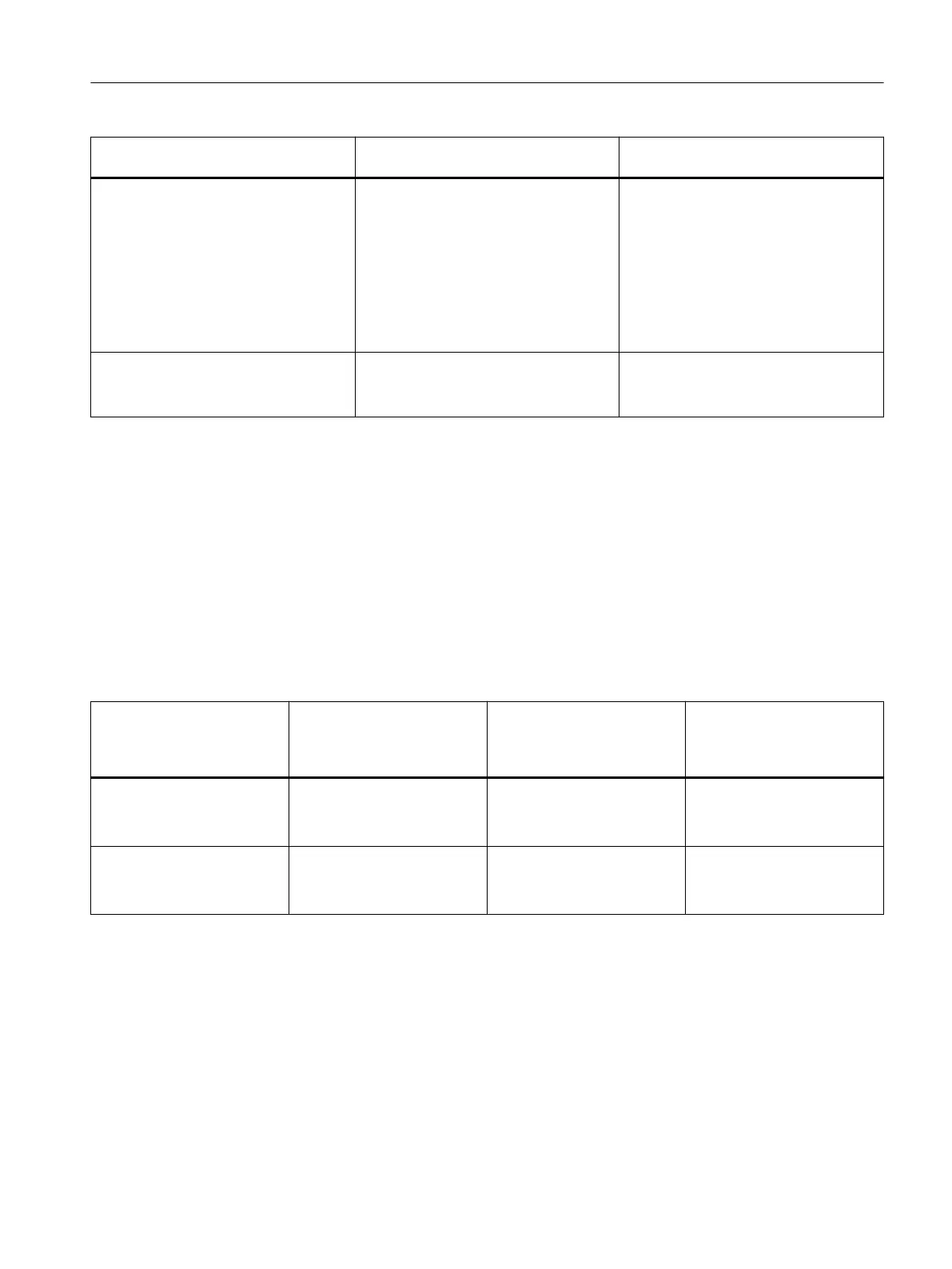

3.1.2.2 Hazardous zones/danger through ammable and potentially explosive sample gas

- rack unit

Place of installation / zone Sample gas non-ammable

below

the lower explosive limit

LEL (25% of LEL)

Flammable sample gas Sample gas is ammable

and/or is

occasionally above the LEL

(25% of LEL)

ATEX II 1G (Zone 0)

Device protection level

Not permissible

(EPL) Ga – not approved

Not permissible

(EPL) Ga – not approved

Not permissible

(EPL) Ga – not approved

ATEX II 2G (Zone 1)

Device protection level

Not permissible

(EPL) Ga – not approved

Not permissible

(EPL) Ga – not approved

Not permissible

(EPL) Ga – not approved

Installing/mounting

3.1Basic safety notes

SIPROCESS GA700 rack and wall mounted devices

Compact Operating Instructions, 06/2023, A5E35134047-AB 29

Loading...

Loading...