See also

Service and maintenance (Page81)

5.4.2.2 Checking ULTRAMAT 7 for leaks

Procedure

1. Close the sample gas/reference gas outlet.

2. Connect the sample gas/reference gas outlet to a pressure measuring instrument

(manometer).

3. Pressurize the sample gas/reference gas path with overpressure of 200 hPa / 400 hPa.

4. Wait for approximately 1minute until the sample gas/reference gas reaches the ambient

temperature.

5. Note the pressure.

6. Wait approximately 5 minutes. Note the pressure again.

If the pressure change lies under 1 hPa, the sample gas/reference gas path is adequately tight.

Calculation of leakage rate

The measured pressure drop is tested against the maximum permissible pressure drop

(calculated from the above data). If the actual pressure drop is greater, the test is considered

failed.

The following applies to the maximum permissible pressure drop:

Δp= t ∙ Q

L

/ V

Δp = max. pressure drop

t = test duration

Q

L

= leakage rate

V = Enclosed volume

The enclosed volume V between gas inlet and outlet is:

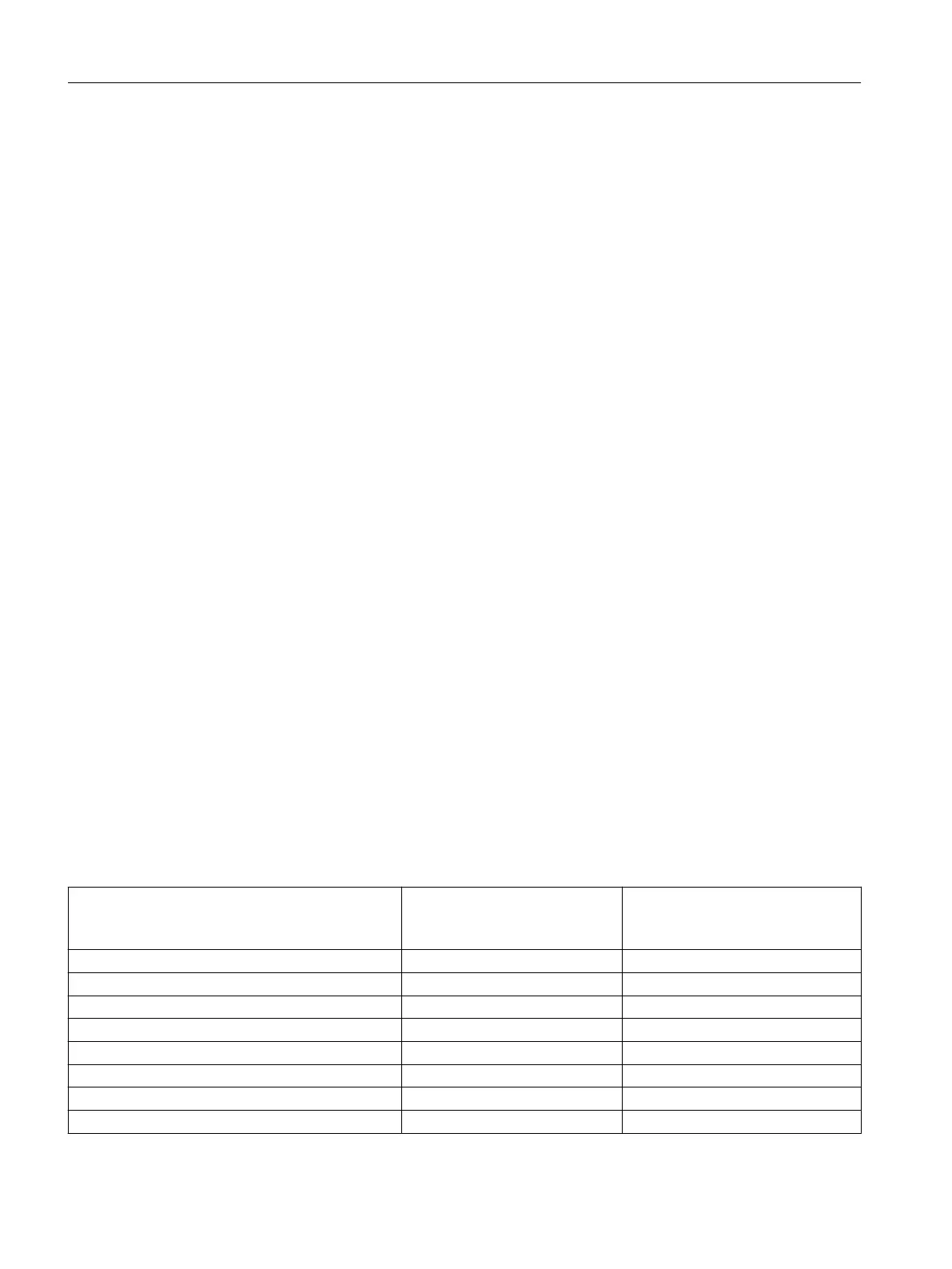

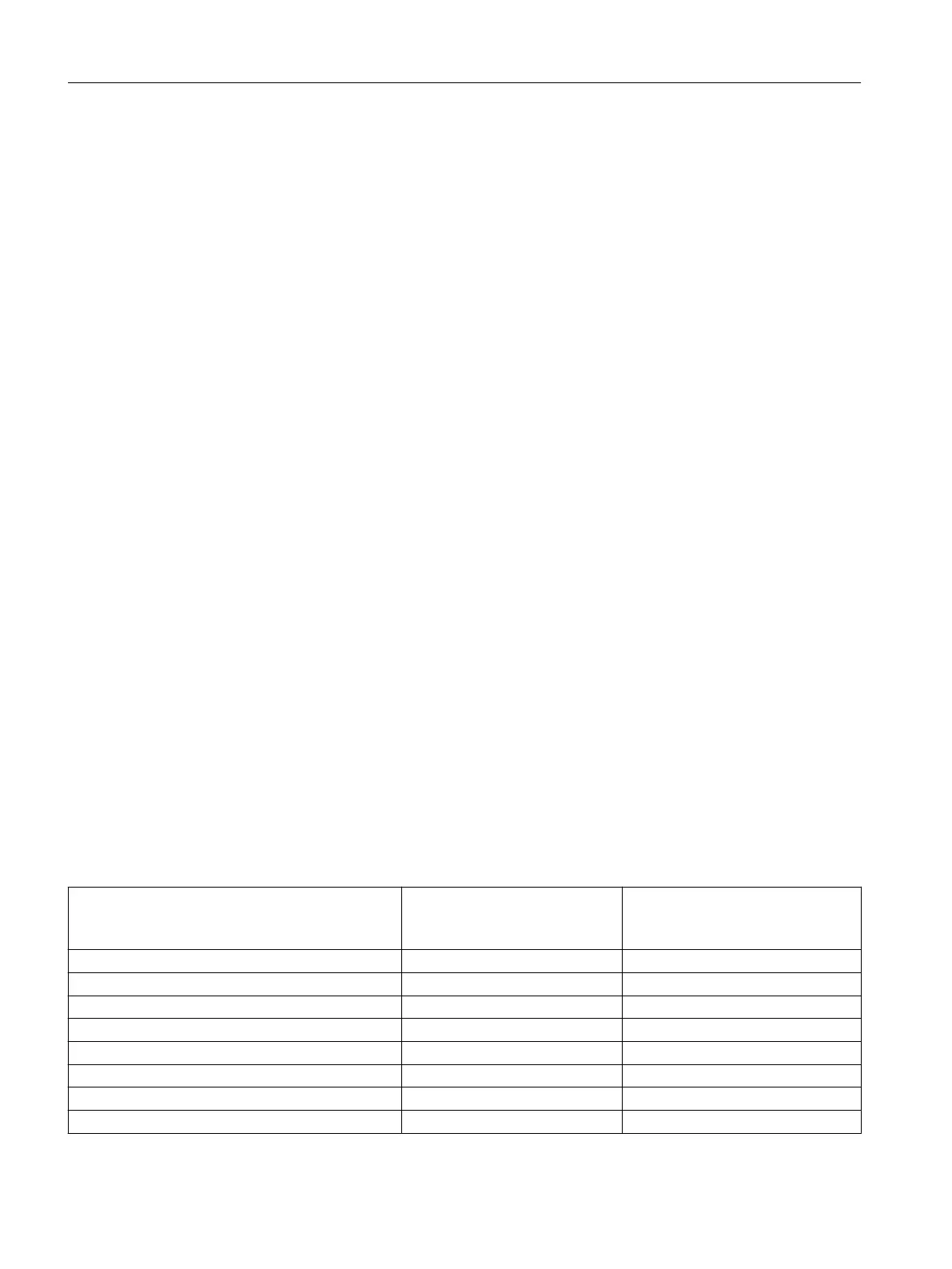

Analysis chamber with gas path [AK mm] Max. permissible pressure drop

Dp [hPa]

Ex variant

Max. permissible pressure drop Dp

[hPa]

Non-Ex variant

0,2 39 78

0,6 36 73

2 31 63

6 22 45

20 14 28

60 4 9

90 3 6

180 1 3

Commissioning

5.4Checking gas paths for leaks

SIPROCESS GA700 rack and wall mounted devices

76 Compact Operating Instructions, 06/2023, A5E35134047-AB

Loading...

Loading...