Edition

2018

Workshop Manual

PARK PRO 340 IX

Chapter

2 Frame and safety guards

Page

17

2.2 Lubrication

For the relative intervention times, see the Maintenance Summary Table in the

“INSTRUCTION MANUAL” (user manual).

Note!

Lubrication is necessary even if the machine is only used for only a few

hours a year.

Note!

Lubrication provides protection not only against wear but also against

rust.

Note!

Lubricate the machine before putting it into storage for a prolonged

period of time.

Lubricate the various parts as described below:

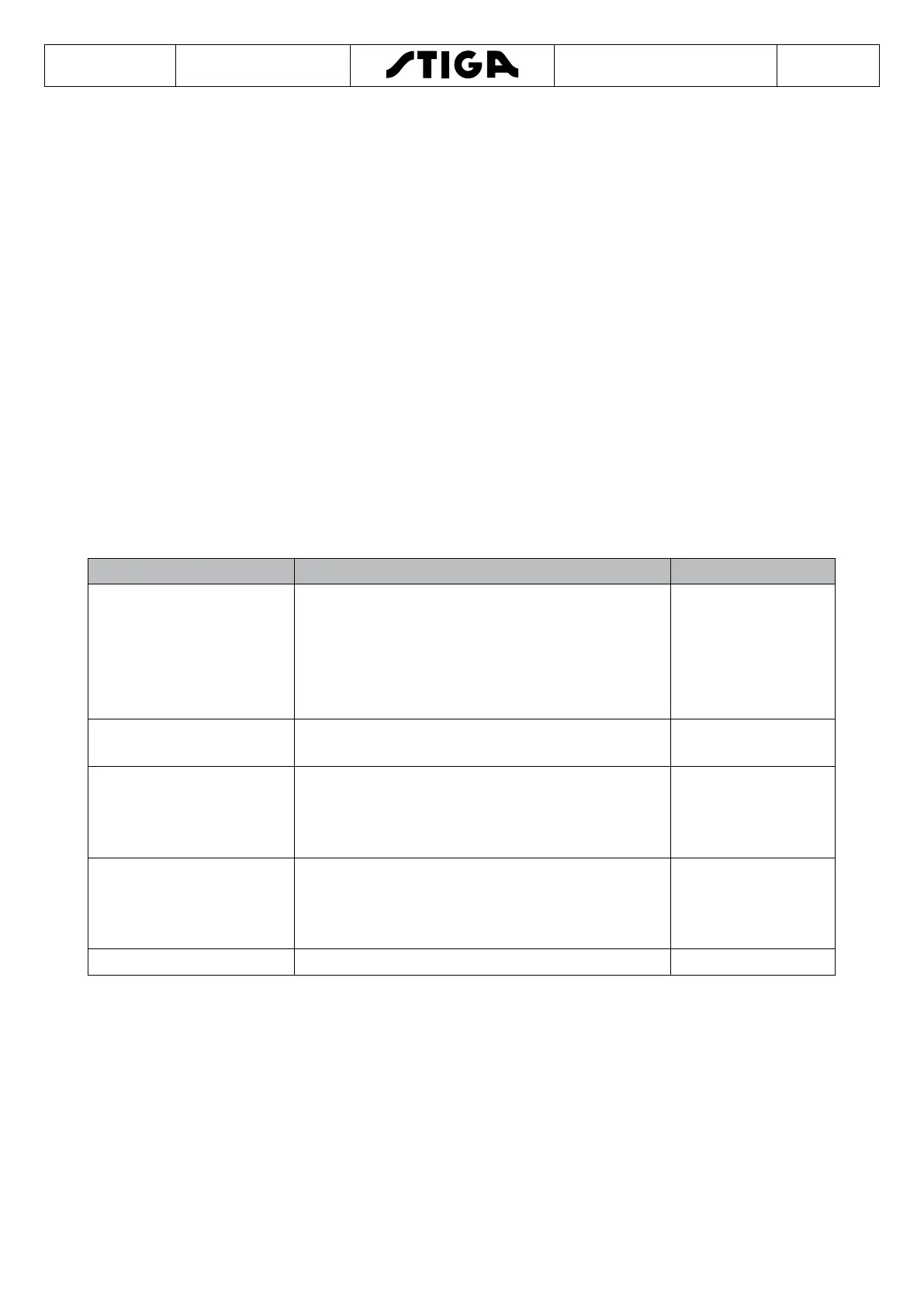

Object Action Pos.

Centre point

3 grease nipples located on the central

articulation on the left-hand side of the

machine.

Use a grease gun lled with universal

grease.

Pump until the grease seeps out.

A

Tensioning arms

Lubricate the support points of the

tensioning arms with oil.

B

Wheel bearings

2 grease nipples.

Use a grease gun lled with universal

grease.

Pump until the grease seeps out.

C

Quick-release

supports

1 grease nipple for each front wheel.

Use a grease gun lled with universal

grease.

Pump until the grease seeps out.

D

Control cabìes Lubricate the control cable ends with oil. E

Loading...

Loading...