TractionLinkageAssembly(continued)

ThetransmissionoftheGroundsmaster360machineconsistsof2pistonpumps.

Theswashplateineachofthepistonpumpsiscontrolledbytheoperatortraction

pedalthroughthetractionlinkageassembly.Correctassemblyofthetraction

linkageassembly(Figure69)isrequiredforpropertractioncircuitoperation.

WhenservicingthetractionlinkageonyourGroundsmaster360machine,use

thefollowinginformation:

Note:RefertotheOperator’sManualforinformationonadjustingtractionpedal

stops,mowspeedlimiterlever,andtractionpedalneutralposition.

1.Thecenterdistancebetweenthetworodends(item41inFigure68)should

be1161mm(45.7inches).Thisisthedistancebetweenthecenterofthe

rodendandthecenteroftherubberbushing(Figure70).T omahhasatool

thatsetsitat1168.4mm(46inches)tobeginandthenitisadjustedoneach

machine.

2.Ifthedualspringhookthatlocatesbehindtheneutralarmspringisremoved,

installthedualspringhooksothatthethreadsextendaftertheangenut

from8.7to9.5mm(0.34to0.37inch)(Figure71).Ifquickerreturntothe

tractionneutralpositionisnecessary,adjustmentcanmadetoincrease

amountofthreadextension.Thisadjustmentwillalsoresultinhigher

pressurerequiredtopressthetractionpedal.

3.Adjustthecontrolarms;refertotheOperator’sManual.

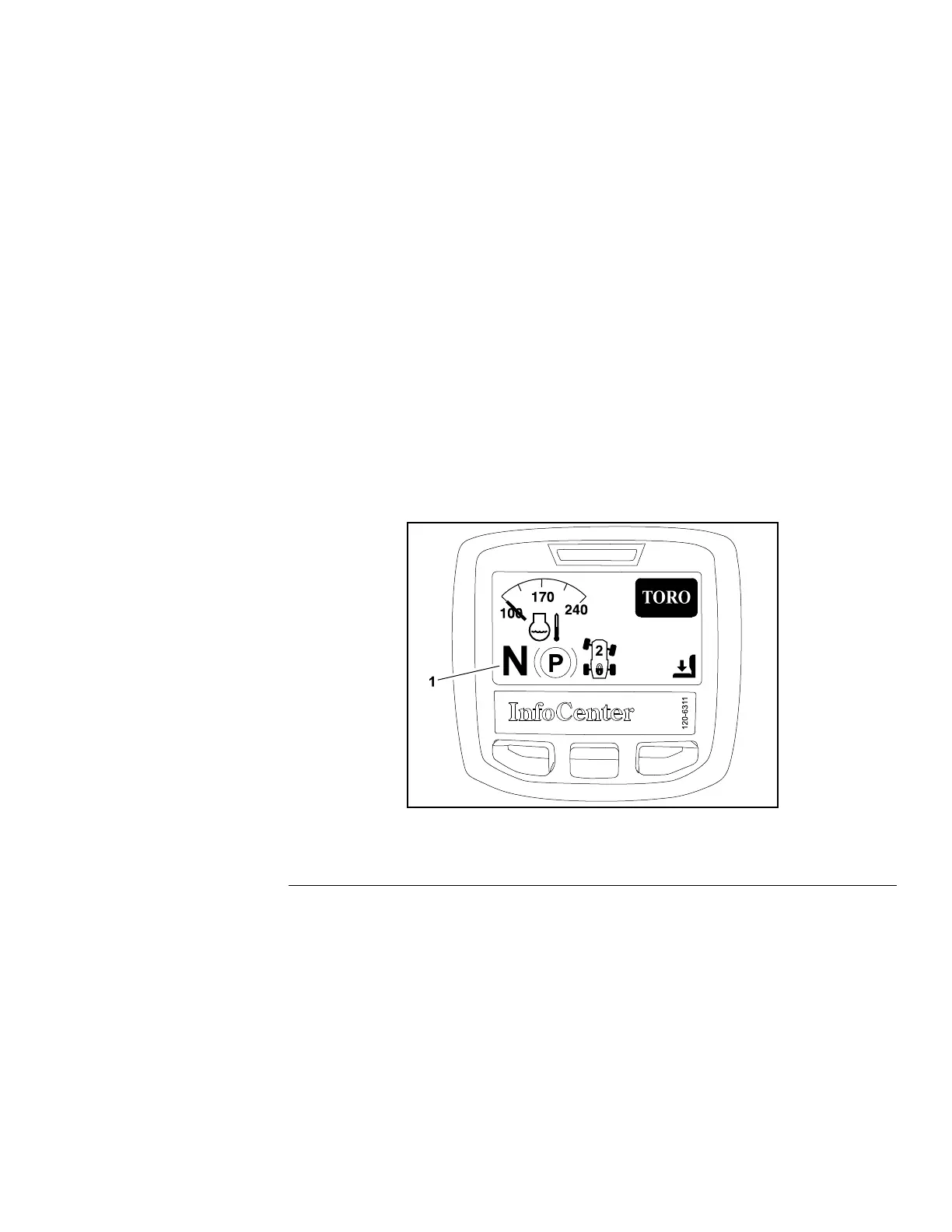

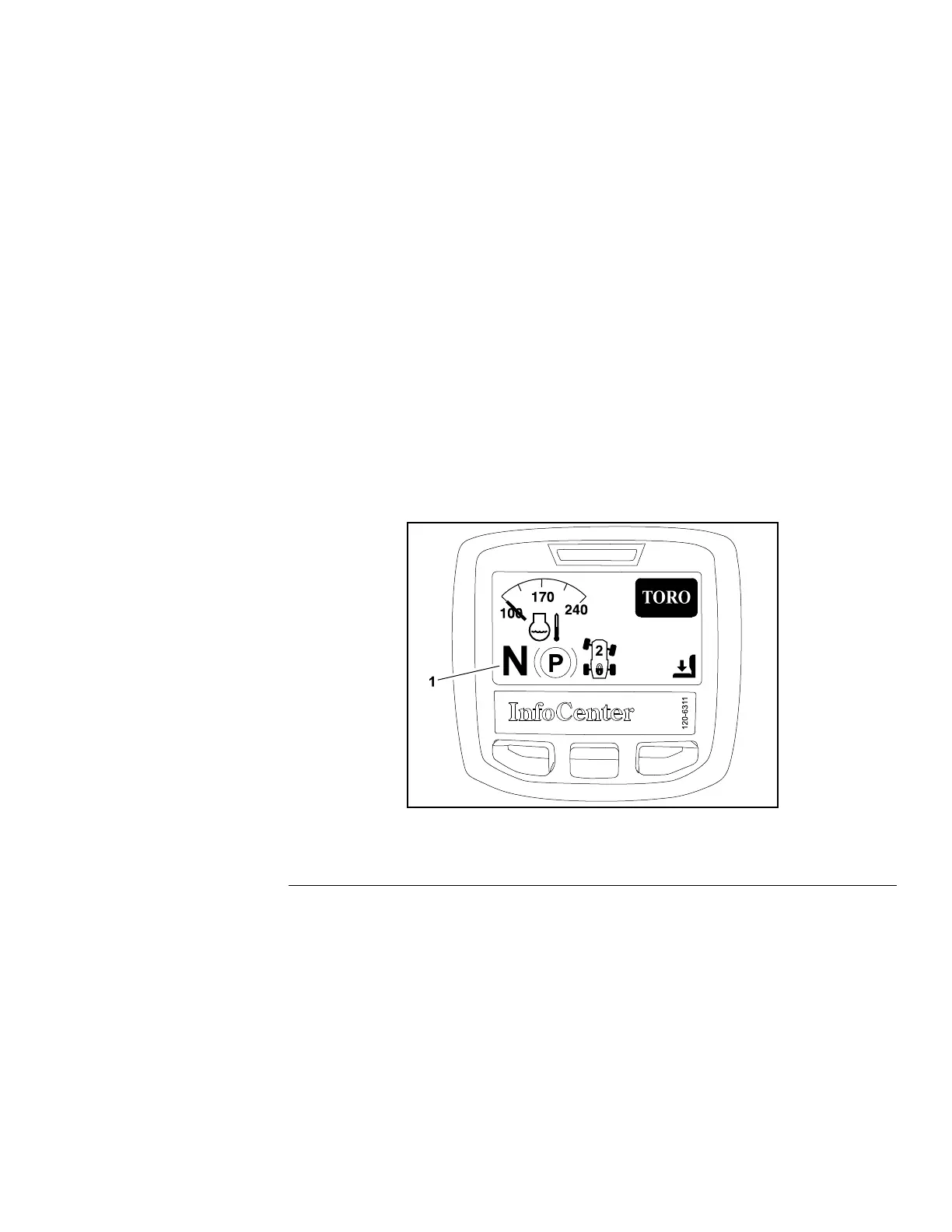

g187656

Figure72

1.Tractionneutralposition

4.Ensurethatthetractionneutralsensorisclosedwhenthetractionpedal

isintheNEUTRALposition:

A.UseInfoCenterdisplaytocheckthetractionneutralsensoroperation

(Figure72).

B.ThetractionneutralsensorLEDshouldbeilluminatedwhenthetraction

pedalisintheNEUTRALposition;refertoTractionNeutralSensor(page

5–43).

5.Afteradjustmentshavebeenmadeandallthetractionlinkagefastenersare

tightened,ensurethatthereisnobindingasthetractionpedalispressed.

ThetractionpedalshouldfreelyreturntotheNEUTRALpositionafteritis

releasedfromeitherforwardorreverse.Also,ensurethatthetractionrod

doesnotcontactanythingthroughbothforwardandreversedirections.

Groundsmaster360

Page4–91

HydraulicSystem:ServiceandRepairs

16225SLRevC

Loading...

Loading...