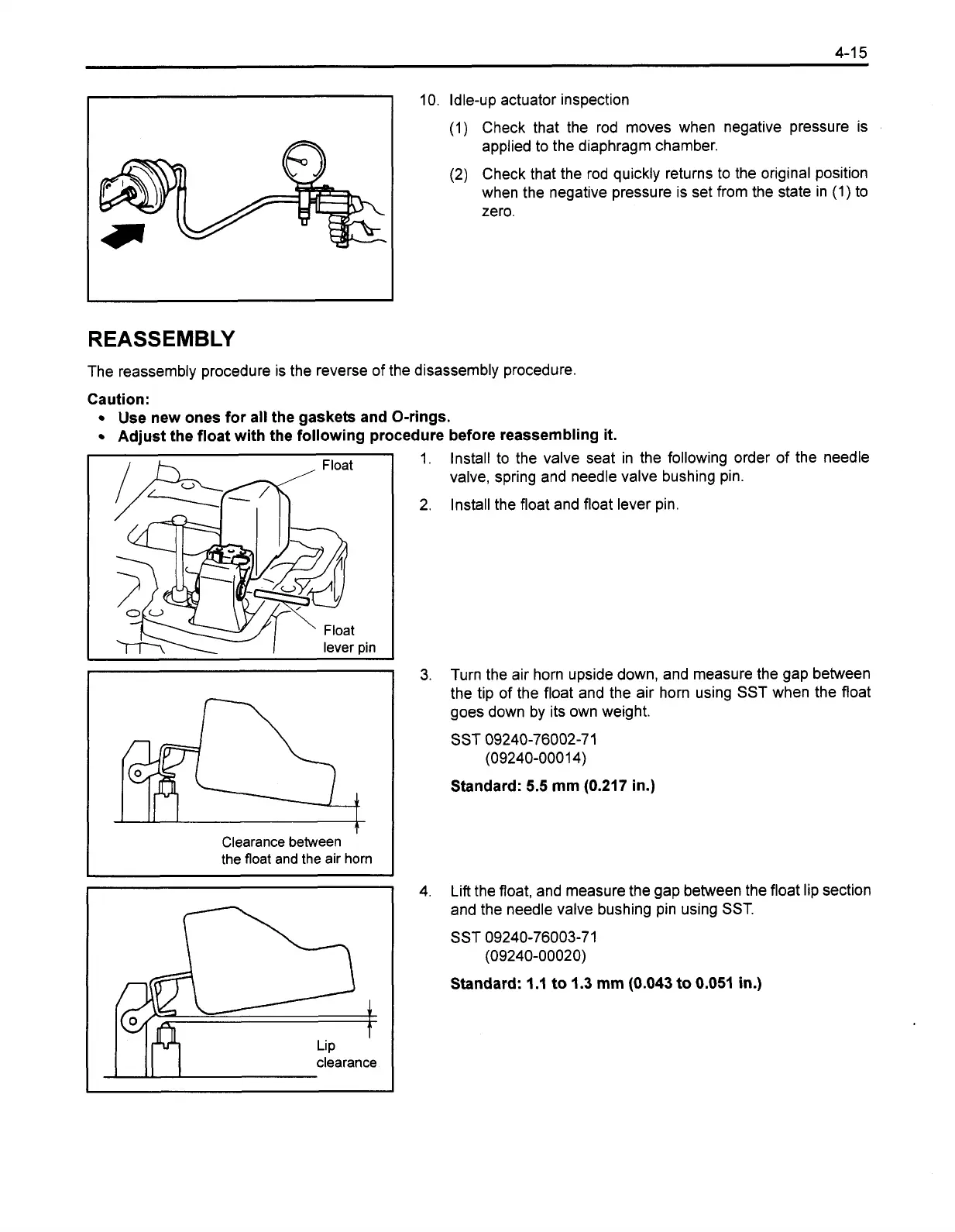

10. Idle-up actuator inspection

(1)

Check that the rod moves when negative pressure is

applied to the diaphragm chamber.

(2) Check that the rod quickly returns to the original position

when the negative pressure is set from the state in

(1) to

zero.

REASSEMBLY

The reassembly procedure is the reverse of the disassembly procedure.

Caution:

Use new ones for all the gaskets and O-rings.

Adjust the float with the following procedure before reassembling it.

pin

Clearance between

the float and the air horn

I

I

(

I

clearance

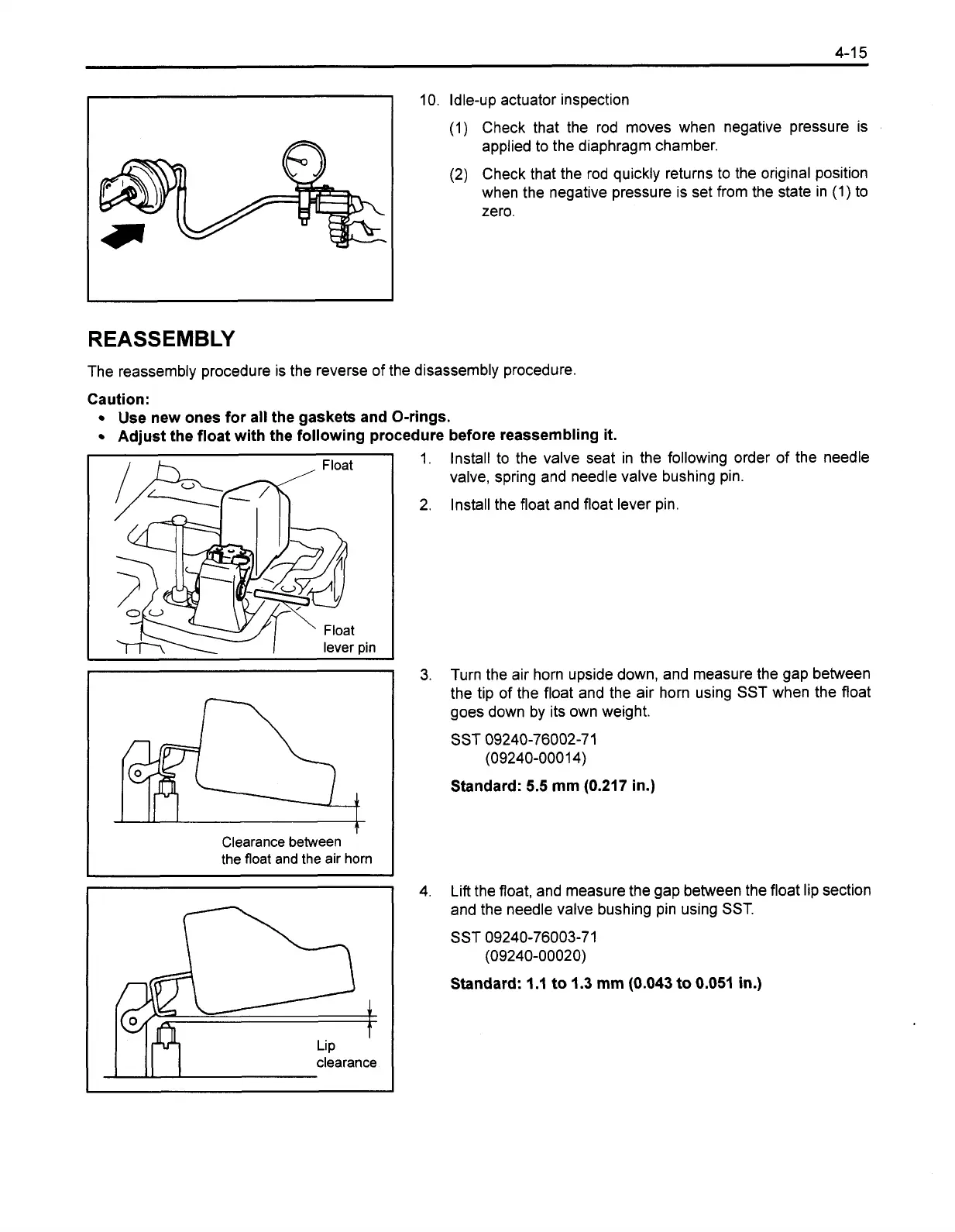

1.

Install to the valve seat in the following order of the needle

valve, spring and needle valve bushing pin.

2,

Install the float and float lever pin.

3.

Turn the air horn upside down, and measure the gap between

the tip of the float and the air horn using

SST

when the float

goes down by its own weight.

SST 09240-76002-7 1

(09240-0001 4)

Standard:

5.5

mm (0.217 in.)

4. Lift the float, and measure the gap between the float lip section

and the needle valve bushing pin using

SST.

SST

09240-76003-71

(09240-00020)

Standard:

I

.I to 1.3

mm

(0.043 to 0.051 in.)

Loading...

Loading...