INSPECTION OF ELECTRIC PARTS

1. Always disconnect the battery plug before performing electric part inspections or maintenance.

2. Be very careful when handling electric parts.

(1)

Do not subject electric parts such as computers or

relays to impacts.

(2) Do not subject electric parts to high temperatures or

humidity.

(3)

Do not touch the connector terminals, because

deformation or static electricity could cause a

malfunction.

I

I.

Use a circuit tester that suits the measurement object and obiective.

Analog system:Useful when viewing movements during operations and when viewing the operation

status. The measured values are used as a reference or as a guideline.

Digital system: Relatively accurate values can be obtained from the measurements. However,

sometimes difficult to understand when viewing operations or movements.

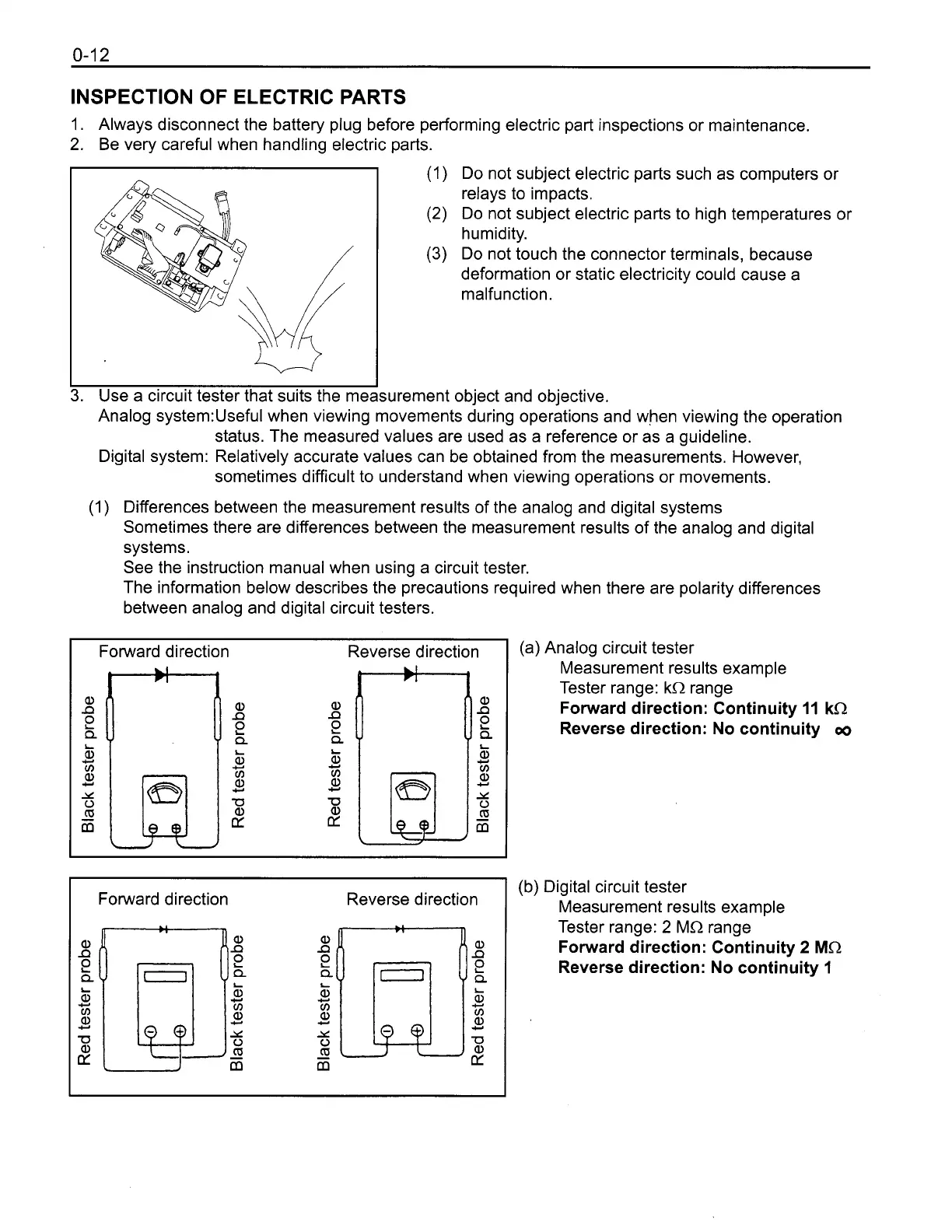

(1) Differences between the measurement results of the analog and digital systems

Sometimes there are differences between the measurement results of the analog and digital

systems.

See the instruction manual when using a circuit tester.

The information below describes the precautions required when there are polarity differences

between analog and digital circuit testers.

Forward direction Reverse direction

Forward direction Reverse direction

(a) Analog circuit tester

Measurement results example

Tester range:

kR range

Forward direction: Continuity

11

kR

Reverse direction: No continuity

oo

(b) Digital circuit tester

Measurement results example

Tester range:

2

MR range

Forward direction: Continuity 2

MR

Reverse direction: No continuity

1

Loading...

Loading...