BA 50Z3/6003 en – Edition 4.3 * 5003b530.fm 5-33

Maintenance

5.12 Tracks

• Track wear can vary according to work and ground conditions.

☞ We recommend checking track wear and tension once a day.

☞ Park the machine on firm, level and horizontal ground to check and perform mainte-

nance.

Raising the machine with the stabilizer blade and the attachment does not

provide adequate safety for work that has to be performed under a raised

machine.

Caution, danger.

☞ Do not allow anyone to stay in the risk zone.

☞ Firmly support the machine with chocks or suitable brackets. Do not dam-

age any parts of the machine as you support it.

Checking the track tension of the rubber tracks

☞ Place the machine on firm, level and horizontal ground.

☞ Raise the machine evenly and horizontally by means of the boom and the stabilizer

blade.

☞ Slowly and carefully actuate the control levers.

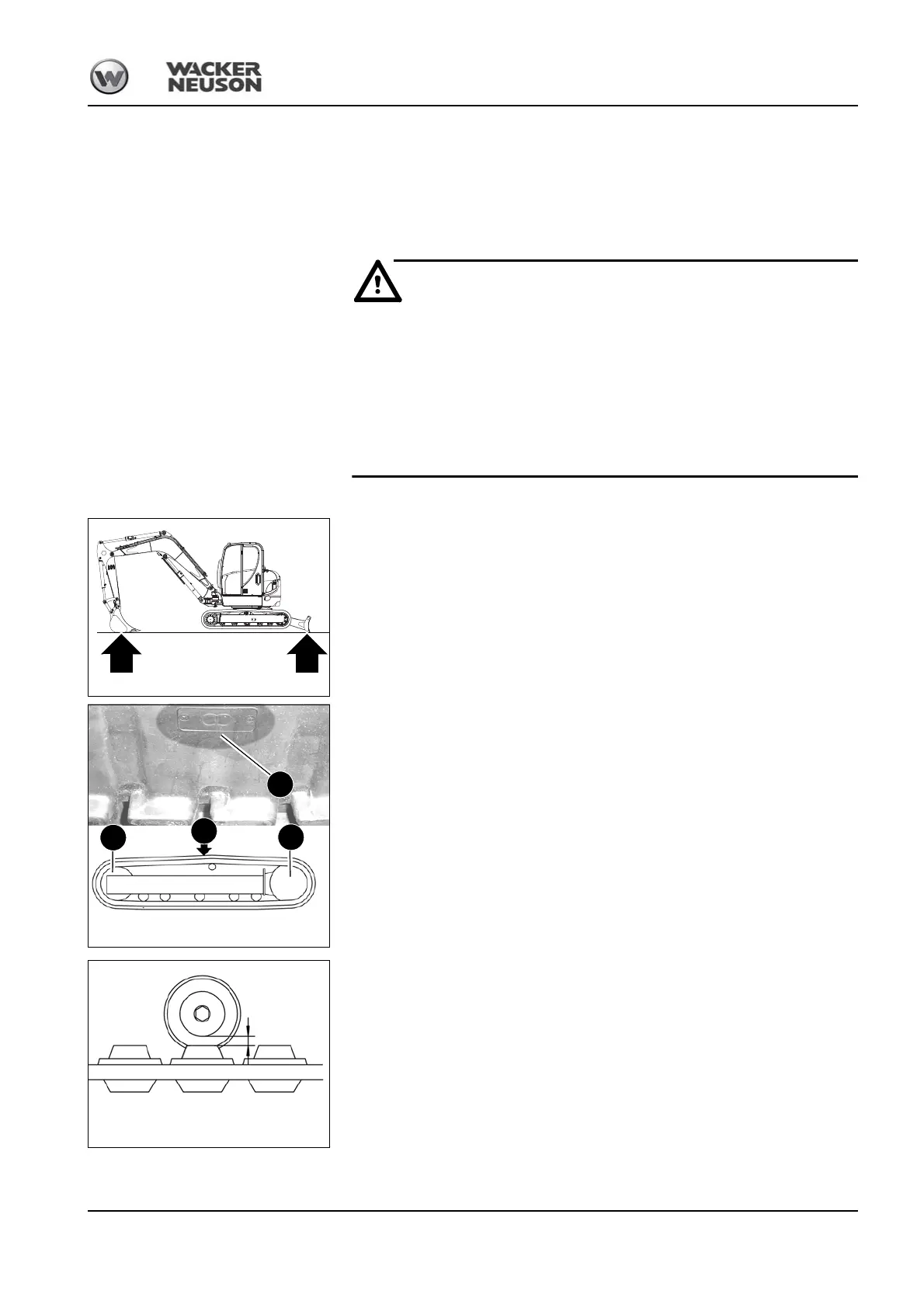

☞ The rubber track has a mark B as shown in Fig. 295.

☞ Place the machine so that mark B of the rubber track is between the drive pinion C and

the track tension roller D.

☞ Stop the engine.

☞ Raise the control lever base.

☞ Remove the ignition key and carry it with you.

☞ Use suitable auxiliary means to support the machine.

• Standard play between the shoulder of the sliding block and the contact area of the

second support roller of the drive pinion is 20 – 25 mm (0.78 – 0.98 in).

☞ Set the tension as follows if it is not in accordance with the rated value – see Adjust-

ing track tension on page 5-34.

Fig. 294: Raising the machine

Fig. 295: Rubber track mark

B

B

D

C

Fig. 296: Measuring distance

20 – 25 mm

(0.78 – 0.98 in)

Maintenance

Loading...

Loading...